Semiconductor manufacturing demands precision and reliability. Coated MOCVD susceptors play a pivotal role in achieving these standards. By utilizing the SiC coating of Graphite substrate for Semiconductor applications, manufacturers enhance thermal stability and chemical resistance. This innovation ensures consistent wafer uniformity, even under extreme conditions. Graphite semiconductor components, when coated with silicon carbide, resist corrosive gases and maintain structural integrity. Sic coated graphite mocvd components automotive industries rely on demonstrate exceptional durability, making them indispensable in high-performance environments. These advancements underscore the importance of sic coated graphite mocvd components in modern semiconductor processing.

Key Takeaways

- Coated MOCVD susceptors make heat stable and resist chemicals better.

- The silicon carbide (SiC) coating spreads heat evenly for thin films.

- SiC-coated susceptors lower contamination, making better and stronger chips.

- These susceptors last longer, cut repair costs, and work more efficiently.

- Good coated susceptors help new tech and meet industry needs today.

What Are Coated MOCVD Susceptors?

Definition and Function

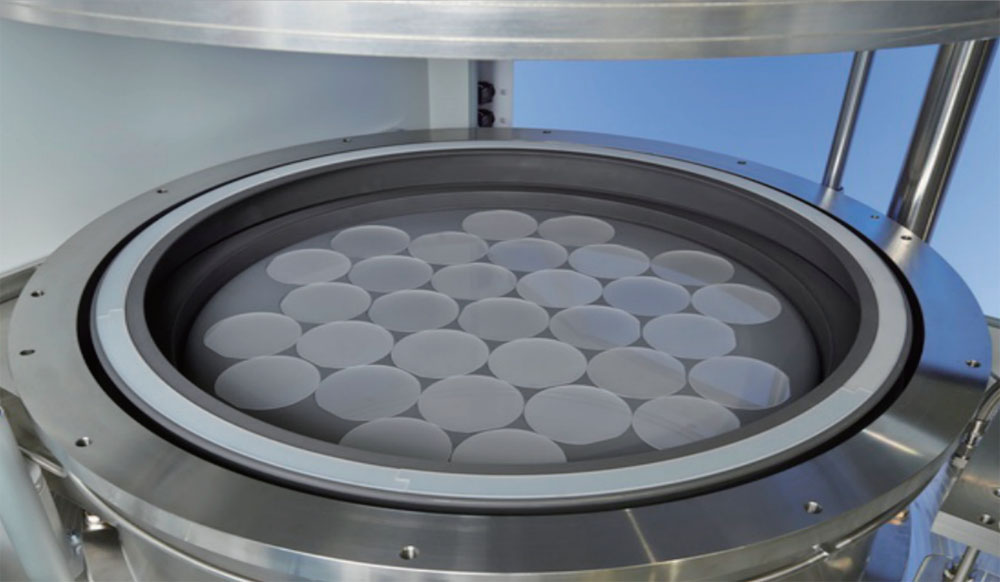

A coated MOCVD Susceptor is a critical component in the Metal-Organic Chemical Vapor Deposition (MOCVD) process. It serves as a platform to hold and heat semiconductor wafers during thin-film deposition. These susceptors are typically made from graphite and coated with silicon carbide (SiC) to enhance their performance. The SiC coating provides superior thermal stability and chemical resistance, ensuring the susceptor can withstand the harsh conditions of semiconductor manufacturing.

The primary function of a coated MOCVD Susceptor is to facilitate uniform heating of wafers. This uniformity is essential for achieving consistent thin-film deposition, which directly impacts the quality and performance of semiconductor devices. By maintaining structural integrity and resisting chemical degradation, these susceptors play a vital role in ensuring reliable and efficient wafer processing.

Role in Semiconductor Manufacturing

Supporting Wafer Processing

Coated MOCVD Susceptors support wafer processing by providing a stable and thermally conductive surface. During the MOCVD process, the susceptor evenly distributes heat across the wafer, preventing temperature fluctuations that could lead to defects. The SiC coating enhances this thermal conductivity, ensuring precise control over the deposition environment. This stability is crucial for producing high-quality semiconductor layers.

Ensuring Uniform Deposition

Uniform deposition is a cornerstone of semiconductor manufacturing. Coated MOCVD Susceptors contribute to this by maintaining consistent temperatures and resisting chemical reactions with process gases. The SiC coating acts as a barrier, protecting the graphite substrate from corrosive gases and preventing contamination. This ensures that the thin films deposited on the wafer are uniform in thickness and composition, which is essential for advanced semiconductor applications.

Note: The use of coated MOCVD Susceptors significantly improves the reliability and efficiency of semiconductor manufacturing processes.

Why Graphite Substrates Are Used

Key Properties of Graphite

High Thermal Conductivity

Graphite exhibits exceptional thermal conductivity, making it an ideal material for MOCVD susceptors. This property allows it to distribute heat evenly across the wafer surface, ensuring precise temperature control during semiconductor processing. The ability to transfer heat efficiently minimizes temperature gradients, which can lead to defects in thin-film deposition. Manufacturers rely on graphite's thermal performance to maintain the consistency and quality of semiconductor layers.

Lightweight and Machinable

Graphite's lightweight nature offers significant advantages in semiconductor manufacturing. Its reduced weight simplifies handling and integration into complex equipment. Additionally, graphite is highly machinable, allowing manufacturers to shape it into intricate designs required for advanced MOCVD susceptors. This machinability ensures that the material can meet the specific demands of modern semiconductor processes without compromising performance.

Challenges of Uncoated Graphite

Chemical Degradation

Uncoated graphite faces significant challenges in the harsh chemical environments of MOCVD processes. Exposure to reactive gases, such as ammonia and hydrogen chloride, can lead to chemical degradation. Over time, this degradation compromises the structural integrity of the susceptor, reducing its effectiveness and lifespan. Without a protective coating, graphite becomes vulnerable to contamination, which can negatively impact wafer quality.

Limited Durability at High Temperatures

Graphite's performance diminishes when exposed to high temperatures for extended periods. In semiconductor manufacturing, where extreme heat is a constant factor, uncoated graphite can oxidize or lose its mechanical strength. This limitation reduces its durability and increases the frequency of replacement, leading to higher operational costs. Coating the graphite with silicon carbide addresses these issues, enhancing its thermal stability and extending its usability.

Note: While graphite offers remarkable properties, its limitations necessitate the use of protective coatings like silicon carbide to unlock its full potential in semiconductor applications.

How SiC Coating Enhances MOCVD Susceptors

Improved Thermal Conductivity

Silicon carbide (SiC) coating significantly enhances the thermal conductivity of a coated MOCVD Susceptor. SiC's high thermal conductivity ensures efficient heat transfer across the susceptor's surface, enabling precise temperature control during wafer processing. This uniform heat distribution minimizes temperature gradients, which are a common cause of defects in thin-film deposition. By maintaining consistent thermal conditions, SiC-coated susceptors improve the quality and reliability of semiconductor layers. Manufacturers benefit from this enhanced thermal performance, as it directly contributes to higher yields and reduced production variability.

Enhanced Durability and Lifespan

The durability of MOCVD susceptors increases substantially with the application of SiC coating. Silicon carbide's exceptional hardness and resistance to wear protect the graphite substrate from mechanical damage and thermal stress. This coating also prevents oxidation, a common issue for uncoated graphite at high temperatures. As a result, SiC-coated susceptors exhibit a longer operational lifespan, reducing the frequency of replacements. This durability translates into lower maintenance costs and improved operational efficiency for semiconductor manufacturers.

Resistance to Chemical Degradation

Protection Against Corrosive Gases

SiC coating acts as a robust barrier against corrosive gases commonly used in the MOCVD process, such as ammonia and hydrogen chloride. These gases can degrade uncoated graphite, compromising its structural integrity. The SiC layer prevents chemical reactions between the gases and the susceptor, ensuring the substrate remains intact. This protection allows the susceptor to maintain its performance even in harsh chemical environments, making it a reliable component in semiconductor manufacturing.

Reduced Contamination Risks

Contamination poses a significant risk to wafer quality during semiconductor processing. Uncoated graphite can release particles or react with process gases, introducing impurities into the deposition environment. SiC coating eliminates this risk by creating a chemically inert surface that resists degradation. This inertness ensures that the coated MOCVD Susceptor does not contribute to contamination, safeguarding the purity of the thin films and enhancing the overall reliability of the manufacturing process.

Tip: SiC-coated susceptors not only improve performance but also reduce long-term costs by minimizing maintenance and contamination-related issues.

Benefits for Semiconductor Processing

Improved Wafer Uniformity

Wafer uniformity is a critical factor in semiconductor manufacturing. Coated MOCVD Susceptors play a pivotal role in achieving this uniformity. The silicon carbide (SiC) coating ensures consistent thermal conductivity across the susceptor's surface. This uniform heat distribution minimizes temperature variations during the deposition process. As a result, thin films deposited on wafers exhibit consistent thickness and composition. This consistency directly impacts the performance and reliability of semiconductor devices. Manufacturers rely on this uniformity to meet the stringent quality standards required for advanced technologies.

Reduced Contamination

Contamination during semiconductor processing can lead to defects and reduced yields. Coated MOCVD Susceptors address this challenge by providing a chemically inert surface. The SiC coating prevents the release of particles and resists reactions with process gases. This protection ensures that the deposition environment remains free from impurities. By reducing contamination risks, these susceptors enhance the purity of thin films and improve overall manufacturing reliability. This capability is especially important in high-precision applications, where even minor impurities can compromise device performance.

Longer Susceptor Lifespan

The lifespan of a susceptor significantly influences operational costs and process efficiency. Coated MOCVD Susceptors offer enhanced durability due to their SiC coating. This coating protects the graphite substrate from chemical degradation and thermal stress. It also prevents oxidation, which is a common issue at high temperatures. These features extend the operational life of the susceptor, reducing the frequency of replacements. Manufacturers benefit from lower maintenance costs and improved process continuity. The longer lifespan of these susceptors contributes to more sustainable and cost-effective semiconductor production.

Enhanced Process Efficiency

Coated MOCVD susceptors significantly enhance process efficiency in semiconductor manufacturing. Their ability to maintain consistent thermal conditions and resist chemical degradation ensures smoother operations and higher productivity.

One of the key contributions of these susceptors lies in their role in reducing downtime. The silicon carbide (SiC) coating protects the graphite substrate from wear and tear, minimizing the need for frequent replacements. This durability allows manufacturers to maintain uninterrupted production cycles, which is critical in high-volume semiconductor fabrication.

Note: Reduced maintenance requirements translate into lower operational costs and improved resource allocation.

The uniform heat distribution provided by SiC-coated susceptors also optimizes energy usage. By ensuring precise temperature control, these components reduce energy waste during the deposition process. This efficiency not only lowers energy costs but also aligns with sustainability goals, making them an environmentally friendly choice for manufacturers.

Additionally, the enhanced chemical resistance of SiC-coated susceptors prevents contamination-related defects. Fewer defects mean higher yields, which directly impacts profitability. Manufacturers can produce more functional devices per batch, reducing material waste and improving overall output.

- Key benefits of enhanced process efficiency include:

- Lower maintenance and replacement costs.

- Reduced energy consumption.

- Higher production yields.

- Minimized material waste.

The integration of coated MOCVD susceptors into semiconductor manufacturing processes exemplifies how advanced materials can drive operational improvements. Their contribution to process efficiency not only benefits manufacturers economically but also supports the industry's push toward more sustainable practices.

Tip: Investing in high-quality coated susceptors can lead to long-term savings and improved manufacturing outcomes.

Industry Applications of Coated MOCVD Susceptors

High-Volume Semiconductor Manufacturing

Coated MOCVD susceptors play a vital role in high-volume semiconductor production. Manufacturers rely on these components to maintain consistent wafer quality across large-scale operations. The silicon carbide (SiC) coating ensures uniform heat distribution and chemical resistance, which are critical for producing defect-free wafers. This reliability allows manufacturers to meet the growing demand for semiconductors in industries such as consumer electronics, automotive, and telecommunications.

In high-volume settings, operational efficiency is paramount. SiC-coated susceptors reduce downtime by minimizing maintenance needs and extending component lifespan. This durability supports uninterrupted production cycles, enabling manufacturers to achieve higher throughput and lower costs.

Tip: Investing in high-quality coated susceptors can significantly enhance productivity in large-scale semiconductor fabrication.

Advanced Node Technologies

The adoption of advanced node technologies requires precision and reliability. Coated MOCVD susceptors provide the thermal stability and chemical resistance needed for these cutting-edge processes. As semiconductor devices shrink to nanometer scales, the margin for error becomes smaller. SiC-coated susceptors ensure uniform thin-film deposition, which is essential for achieving the high performance and efficiency demanded by advanced nodes.

These susceptors also support the development of next-generation technologies, including 5G, artificial intelligence, and quantum computing. Their ability to maintain wafer purity and consistency makes them indispensable for manufacturing the complex chips required for these applications.

Examples of Industry Adoption

Leading semiconductor manufacturers have widely adopted coated MOCVD susceptors. Companies producing high-performance chips for smartphones, electric vehicles, and data centers rely on these components to meet stringent quality standards. For example, the automotive industry uses SiC-coated susceptors to produce power electronics for electric vehicles, where durability and efficiency are critical.

Note: The widespread use of coated MOCVD susceptors highlights their importance in driving innovation and meeting the demands of modern semiconductor applications.

Coated MOCVD Susceptors have revolutionized semiconductor manufacturing by addressing critical challenges in wafer processing. Their SiC-coated graphite design enhances thermal stability, chemical resistance, and wafer uniformity, ensuring consistent performance under demanding conditions. These advancements reduce contamination risks, extend component lifespan, and improve process efficiency. By enabling precise thin-film deposition, they support the development of cutting-edge technologies. Their role in advancing semiconductor technology highlights their importance in meeting the growing demands of modern industries.

FAQ

What is the primary purpose of a coated MOCVD susceptor?

A coated MOCVD susceptor ensures uniform wafer heating during the deposition process. Its silicon carbide (SiC) coating enhances thermal stability and chemical resistance, enabling precise thin-film deposition. This uniformity directly impacts the quality and performance of semiconductor devices.

Why is silicon carbide (SiC) used as a coating material?

Silicon carbide offers exceptional thermal conductivity, chemical resistance, and durability. It protects the graphite substrate from corrosive gases and high temperatures, extending the susceptor's lifespan. These properties make SiC an ideal choice for demanding semiconductor manufacturing environments.

How do coated MOCVD susceptors reduce contamination risks?

The SiC coating creates a chemically inert surface that resists reactions with process gases. This prevents particle release and contamination during wafer processing. By maintaining a clean deposition environment, coated susceptors improve wafer purity and manufacturing reliability.

What industries benefit from coated MOCVD susceptors?

Industries like consumer electronics, automotive, and telecommunications rely on coated MOCVD susceptors. These components support high-volume semiconductor production and advanced technologies, including 5G, artificial intelligence, and electric vehicles, by ensuring consistent wafer quality and process efficiency.

How do coated MOCVD susceptors improve manufacturing efficiency?

Coated susceptors enhance efficiency by reducing maintenance needs and extending operational lifespans. Their uniform heat distribution minimizes defects, increasing production yields. Additionally, their chemical resistance lowers contamination risks, ensuring smoother operations and higher productivity in semiconductor fabrication.

Tip: Investing in high-quality coated susceptors can lead to long-term cost savings and improved manufacturing outcomes.