![]()

Ceramic custom SiC coating solutions are set to play a crucial role in advanced industries by 2025. The durability and resilience of ceramic custom SiC coating make it vital for applications in aerospace, semiconductors, and clean energy sectors. With global defense budgets surpassing $2.2 trillion in 2023, investments in advanced materials, including ceramic SiC coating, have significantly increased. Cutting-edge innovations like laser-assisted chemical vapor deposition (LACVD) and CVD tac Coating have further improved the precision and performance of these coatings. As industries continue to seek materials with exceptional thermal stability and chemical resistance, ceramic custom SiC coating and ceramic SiC coating solutions remain at the forefront of addressing modern industrial challenges with unparalleled reliability.

Key Takeaways

- Ceramic SiC coatings are very strong and resist wear. They work well in tough places like aerospace and semiconductors.

- SiC coatings can be customized to fit specific needs. This improves how they work and helps parts last longer.

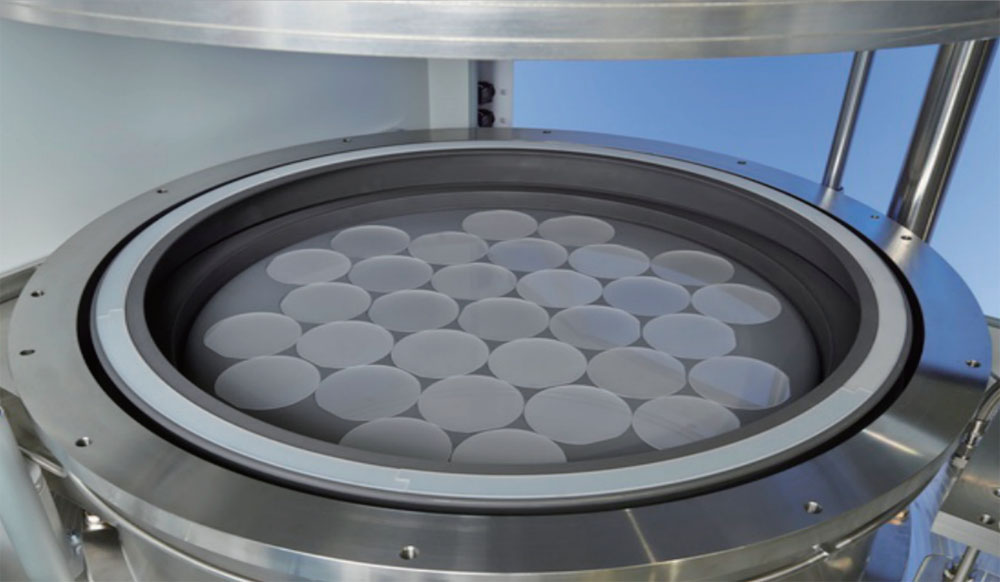

- Special methods, like chemical vapor deposition, make SiC coatings even and precise. This ensures they work reliably.

- Using ceramic SiC coatings can save money on repairs. In some cases, blade replacements happen 40% less often.

- The demand for SiC coatings is growing fast. Renewable energy and car industries are driving this growth, making them a smart choice for the future.

What Are Ceramic Custom SiC Coating Solutions?

Definition and Composition

Ceramic custom SiC coating solutions refer to specialized silicon carbide (SiC) coatings designed to meet specific industrial needs. These coatings consist of silicon and carbon atoms arranged in a crystalline structure, which provides exceptional hardness and thermal stability. Manufacturers often apply these coatings using advanced techniques like chemical vapor deposition (CVD) to ensure uniformity and precision. The ability to customize the composition allows industries to tailor the coatings for unique applications, such as enhancing resistance to extreme temperatures or corrosive environments.

Key Properties and Characteristics

Silicon carbide coatings exhibit several remarkable properties that make them indispensable in modern industries. Their hardness, measured at room temperature, reaches approximately 486 ± 16 GPa, surpassing many other materials. This high hardness ensures excellent wear resistance, even under challenging conditions. Additionally, the elastic modulus of SiC coatings, which measures stiffness, shows minimal reduction with increasing temperature. For example, UMAN and CEA coatings demonstrate slight decreases in elastic modulus values, with coefficients of -0.05 ± 0.04 and -0.07 ± 0.04, respectively. These characteristics make ceramic custom SiC coating solutions ideal for applications requiring durability and stability.

Importance of Customization

Customization plays a pivotal role in the effectiveness of ceramic custom SiC coating solutions. Different industries face unique challenges, such as exposure to high temperatures, abrasive materials, or corrosive chemicals. By tailoring the coating's composition and thickness, manufacturers can address these specific needs. For instance, aerospace applications may require coatings optimized for thermal resistance, while semiconductor industries prioritize chemical stability. Customization ensures that the coatings deliver maximum performance and extend the lifespan of critical components.

Tip: Custom SiC coatings not only enhance performance but also reduce maintenance costs by minimizing wear and tear on equipment.

Manufacturing Processes for Ceramic Custom SiC Coatings

Overview of Key Techniques

Manufacturing ceramic custom SiC coating solutions involves advanced techniques to ensure precision and durability. Chemical vapor deposition (CVD) is one of the most widely used methods. It creates a uniform coating by depositing silicon carbide onto a substrate through chemical reactions in a controlled environment. Thermal spraying is another popular technique. It involves heating SiC particles and spraying them onto surfaces to form a protective layer. Both methods allow manufacturers to achieve coatings with exceptional hardness and thermal stability.

Other techniques, such as physical vapor deposition (PVD) and plasma-enhanced CVD, are also gaining traction. These methods offer enhanced control over coating thickness and microstructure, making them ideal for applications requiring high precision.

Steps Involved in the Manufacturing Process

The manufacturing process for ceramic custom SiC coatings follows a series of well-defined steps. Each step ensures the final product meets industry standards for performance and reliability. The table below outlines the key steps:

| Step | Description |

|---|---|

| Consolidation | Ceramic powder is shaped, either through wet or dry forming methods. |

| Binder Burnout | Binders are burned out to create a green body. |

| Sintering | The green body is sintered, allowing ceramic particles to enlarge and join, forming a dense product. |

| Joining and Metallization | The formed ceramic is joined to housing materials, often using brazing techniques for hermetic seals. |

These steps ensure the coatings are robust and capable of withstanding extreme conditions.

Quality Control and Performance Testing

Quality control is critical in the production of ceramic custom SiC coating solutions. Manufacturers use various methods to ensure the coatings meet stringent performance standards. The table below highlights some of the most common quality control techniques:

| Quality Control Method | Description |

|---|---|

| Non-Destructive Testing | Techniques like X-ray computed tomography and ultrasonic inspection ensure the integrity of the coatings without damaging them. |

| Mechanical Testing | Includes flexural strength testing and hardness testing to evaluate the performance of the coatings under stress. |

| Dimensional Inspection | Utilizes tools like coordinate measuring machines (CMM) to ensure precise dimensions of the coatings. |

| Microstructural Analysis | Employs methods such as scanning electron microscopy (SEM) to analyze the microstructure of the coatings for quality assurance. |

These methods help manufacturers maintain consistency and reliability in their products. By combining advanced manufacturing techniques with rigorous quality control, ceramic custom SiC coating solutions deliver exceptional performance across various industries.

Benefits of Ceramic Custom SiC Coating Solutions

Durability and Wear Resistance

Ceramic custom SiC coating solutions are renowned for their exceptional durability and wear resistance. These coatings protect surfaces from abrasion, extending the lifespan of critical components in demanding environments. Industries rely on rigorous testing methods to validate this durability.

| Testing Method | Description |

|---|---|

| Pin-on-Disk / Ball-on-Disk Tests | Measures friction and wear over a controlled contact area and sliding distance. |

| Taber Abrasion Test | Quantifies weight or volume loss after a set number of abrasion cycles with a rotating wheel. |

| Dry Sand / Rubber Wheel Test | Evaluates abrasion resistance under controlled sand flow and wheel rotation, simulating real-world conditions. |

These tests demonstrate the coatings' ability to withstand harsh conditions, making them ideal for applications in aerospace, semiconductors, and other high-stress industries.

Thermal and Chemical Stability

The thermal and chemical stability of ceramic custom SiC coating solutions ensures reliable performance in extreme environments. Experimental results highlight the coatings' ability to maintain stability even at elevated temperatures. For instance, coatings produced through Electrophoretic Deposition, enhanced with SiO₂ and a Black dye, achieve emissivity values of approximately 0.89 at room temperature and 0.82 at 550 ºC. These additives also improve thermal stability, with absorbance levels exceeding 85% in the near-infrared spectral range over extended periods. This stability makes the coatings indispensable for industries requiring resistance to high temperatures and corrosive chemicals.

Cost-Effectiveness and Efficiency

While ceramic custom SiC coatings may have a higher initial cost, their long-term benefits outweigh the expense. A cost analysis reveals that SiC coatings reduce blade replacement frequency by 40% compared to alumina alternatives, making them a cost-effective choice for high-stress environments.

| Material Type | Cost Comparison | Performance Advantage |

|---|---|---|

| Zirconia | 30-40% lower | Adequate hardness and fracture toughness for non-critical components |

| SiC | Higher cost | Dominates in high-stress environments with 40% less blade replacement frequency compared to alumina alternatives |

| Si₃N₄-SiC Composite | Competitive | 20% higher fracture toughness, extending service life in photovoltaic applications |

| Aluminum Nitride | Lower CO₂ emissions | Lower embodied carbon compared to SiC, influencing material choice in Europe |

By reducing maintenance costs and extending the lifespan of components, these coatings provide significant economic advantages for industries worldwide.

Applications of Ceramic Custom SiC Coating Solutions

Aerospace and Defense

Ceramic custom SiC coating solutions play a vital role in aerospace and defense industries. These coatings are commonly applied to turbine blades, nozzles, and armor plates. Their high strength and resistance to wear and corrosion ensure that critical components maintain structural integrity under extreme conditions. The thermal stability of SiC coatings allows them to perform reliably in high-pressure and high-temperature environments, such as jet engines and missile systems.

- Key performance highlights include:

- Exceptional resistance to wear and corrosion, extending the lifespan of components.

- High thermal stability, ensuring functionality in extreme heat.

- Superior strength, which is essential for maintaining structural integrity.

These properties make ceramic custom SiC coatings indispensable for enhancing the durability and efficiency of aerospace and defense equipment.

Semiconductor and Electronics

In the semiconductor and electronics industries, ceramic custom SiC coating solutions are essential for improving performance and reliability. These coatings protect sensitive components from thermal and chemical damage, ensuring consistent operation in demanding environments. Their high hardness and elastic modulus provide excellent mechanical stability, which is critical for precision manufacturing processes.

| Metric | Value (at Room Temperature) | Notes |

|---|---|---|

| Hardness | ~35 GPa | Similar across three coatings despite different microstructural features |

| Elastic Modulus | 340 - 400 GPa | Varies among coatings; decreases with temperature |

The ability to withstand extreme conditions makes SiC coatings a preferred choice for semiconductor manufacturing equipment and electronic devices.

Energy and Power Generation

Ceramic custom SiC coating solutions significantly enhance efficiency in energy and power generation industries. SiC power devices improve energy conversion efficiency in electric vehicles and renewable energy systems. Their low conduction loss and high voltage blocking ability reduce energy waste and operating costs.

- In solar and wind energy inverters, SiC technology boosts energy conversion efficiency and lowers operating temperatures.

- SiC-based power electronics enable the development of compact and efficient power converters, reducing costs and improving reliability.

- Grid-connected inverters for solar systems benefit from SiC coatings, supporting the growth of renewable energy by enhancing system performance.

These advancements demonstrate how ceramic custom SiC coatings contribute to sustainable energy solutions while optimizing performance and reducing costs.

Emerging applications in other industries

Ceramic custom SiC coating solutions are finding new applications across a variety of industries. Their unique properties, such as high durability, thermal stability, and chemical resistance, make them suitable for innovative uses beyond traditional sectors.

In the field of metalworking, these coatings enhance the performance of cutting tools. The wear resistance of SiC coatings allows tools to maintain sharpness and durability, even under intense conditions. This reduces tool replacement frequency and improves operational efficiency.

Industries operating in chemically aggressive environments also benefit from these coatings. SiC coatings protect components exposed to corrosive substances, ensuring longer lifespans and reduced maintenance costs. For example, chemical processing plants use these coatings to safeguard equipment from acid or alkali damage.

Optical systems represent another emerging application. High-purity SiC blanks are now used to create mirrors for telescopes and precision optical instruments. These mirrors offer exceptional stability and performance, even in extreme conditions. Space exploration has also adopted SiC coatings for lightweight, high-performance mirrors and structural components. These materials are critical for satellites and other space-based systems where weight and durability are key factors.

In power electronics, SiC coatings serve as substrate materials for next-generation semiconductor devices. These devices improve energy efficiency and performance in applications like electric vehicles and renewable energy systems. The ability to handle high voltages and temperatures makes SiC coatings indispensable in this sector.

The table below summarizes these emerging applications:

| Application Area | Description |

|---|---|

| Wear Resistance | Used in metal cutting tools to enhance durability and performance. |

| Corrosive Environment Protection | Protects components in environments that are chemically aggressive. |

| Optical Systems | Large, high-purity SiC blanks are utilized for mirrors in telescopes and precision optical systems. |

| Space Exploration | Development of lightweight, high-performance mirrors and structural components for space-based systems. |

| Power Electronics | Substrate material for next-generation wide-bandgap semiconductor devices, enhancing efficiency. |

These emerging applications highlight the versatility of ceramic custom SiC coating solutions. As industries continue to innovate, the demand for these coatings will likely grow, driving advancements in technology and sustainability.

Comparing Ceramic Custom SiC Coatings with Alternatives

SiC Coatings vs. Other Ceramic Coatings

Ceramic custom SiC coating solutions stand out when compared to other ceramic coatings due to their superior performance metrics. These coatings offer exceptional surface smoothness, with a surface roughness of Ra = 0.8µm, Rz = 5µm, and Rt = 8µm. Their high purity levels and excellent adhesion make them ideal for applications requiring precision and durability. Other ceramic coatings often vary in these properties, making them less reliable for demanding environments.

| Metric | Ceramic Custom SiC Coatings | Other Ceramic Coatings |

|---|---|---|

| Surface Roughness | Ra = 0.8µm, Rz = 5µm, Rt = 8µm | Varies |

| Coating Adhesion | Excellent adhesion with high purity | Varies |

| Penetration Depth | 10 µm at 5.5 mm depth in small holes | Varies |

| Purity Levels | High purity silicon carbide coating | Varies |

The table highlights the consistency and precision of SiC coatings, making them a preferred choice for industries like aerospace and semiconductors.

SiC Coatings vs. Metallic Coatings

When compared to metallic coatings, SiC coatings offer distinct advantages. Metallic coatings, while cost-effective, often lack the thermal and chemical stability required for extreme environments. SiC coatings excel in these areas, maintaining their integrity under high temperatures and corrosive conditions. Additionally, their hardness and wear resistance far surpass those of metallic alternatives, ensuring longer-lasting protection for critical components.

For example, in high-temperature applications, metallic coatings may degrade or oxidize, leading to frequent maintenance. SiC coatings, on the other hand, remain stable, reducing downtime and operational costs. This makes them a more efficient and reliable solution for industries requiring robust performance.

Key Factors in Selecting a Coating Solution

Selecting the right coating solution depends on several factors. Industries must consider the operating environment, including temperature, chemical exposure, and mechanical stress. The desired lifespan of the coated component also plays a crucial role. SiC coatings are ideal for applications requiring high durability, thermal stability, and resistance to wear and corrosion.

Cost is another important factor. While SiC coatings may have a higher initial cost, their long-term benefits, such as reduced maintenance and extended component life, often justify the investment. Industries should evaluate these factors carefully to choose a coating solution that meets their specific needs.

Tip: Always assess the compatibility of the coating material with the substrate to ensure optimal performance and adhesion.

Future Trends in Ceramic Custom SiC Coating Solutions

Innovations in Nanotechnology

Nanotechnology is revolutionizing ceramic custom SiC coating solutions by enhancing their performance at the molecular level. Researchers are developing nanostructured SiC coatings with improved hardness, wear resistance, and thermal stability. These coatings exhibit superior surface smoothness and reduced porosity, making them ideal for high-precision applications. For instance, nanotechnology enables the creation of ultra-thin coatings that maintain their integrity under extreme conditions. This advancement is particularly beneficial for industries like aerospace and semiconductors, where precision and durability are critical.

Nanotechnology also facilitates the integration of functional additives into SiC coatings. These additives enhance properties such as electrical conductivity and thermal emissivity, expanding the range of applications. As nanotechnology continues to evolve, it is expected to drive further innovation in SiC coatings, making them more versatile and efficient.

Sustainability and Eco-Friendly Advancements

Sustainability is becoming a key focus in the development of ceramic custom SiC coating solutions. Manufacturers are exploring bio-based and recycled materials to reduce the environmental impact of these coatings. According to Unterweger, a leading researcher, "We are offering basically the same mechanical performance and temperature resistance as standard SiC but with a high bio-based content." Efforts are underway to replace non-sustainable components, such as novolac phenolic resin, with alternatives like lignin. These advancements aim to create coatings made entirely from bio-based, recycled, or sustainable materials.

Eco-friendly SiC coatings also contribute to energy efficiency by reducing wear and extending the lifespan of components. This minimizes waste and lowers the carbon footprint of industrial processes. As industries prioritize sustainability, the demand for environmentally friendly SiC coatings is expected to grow.

Market Growth and Emerging Applications in 2025

The market for ceramic custom SiC coating solutions is poised for significant growth. Market research projects a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030 in the semiconductor sector. Key drivers include the rising demand for SiC power devices, advancements in deposition techniques, and increased applications in renewable energy and automotive industries. The table below highlights these trends:

| Aspect | Details |

|---|---|

| Market Growth Rate | Expected CAGR of 4.5% from 2024 to 2030 for SiC coatings in the semiconductor market. |

| Major Drivers | Growing demand for SiC power devices, advancements in semiconductor manufacturing, and regulatory concerns. |

| Emerging Trends | Advances in deposition techniques, increased automotive applications, and integration with renewable energy. |

| Regional Growth | APAC expected to witness the highest growth due to demand for renewable energy and established semiconductor industry. |

| Cost Efficiency | Innovations in material processing to reduce costs and increase adoption of SiC coatings. |

Emerging applications include pharmaceutical equipment, consumer goods, and next-generation power electronics. These sectors are leveraging the unique properties of SiC coatings to improve efficiency and performance. As industries continue to innovate, the market for SiC coatings will expand, offering new opportunities for growth and development.

Ceramic custom SiC coating solutions offer unmatched durability, thermal stability, and chemical resistance. These properties make them indispensable across industries like aerospace, semiconductors, and renewable energy. Their ability to extend component lifespans and reduce maintenance costs highlights their economic and operational value.

Industries are increasingly adopting these coatings to tackle modern challenges. The global ceramic composites market is expected to reach $5 billion by 2027, with a CAGR of 8% from 2023 to 2027. Sectors such as aerospace and automotive are driving this growth by prioritizing lightweight, high-performance materials.

Adopting ceramic custom SiC coating solutions ensures industries remain competitive and sustainable. Their versatility and efficiency make them a future-ready choice for addressing evolving industrial demands.

FAQ

What makes ceramic custom SiC coatings unique compared to other materials?

Ceramic custom SiC coatings stand out due to their exceptional hardness, thermal stability, and chemical resistance. These properties make them ideal for extreme environments. Unlike metallic coatings, SiC coatings maintain their integrity under high temperatures and resist wear, ensuring longer-lasting performance.

How are ceramic custom SiC coatings applied to surfaces?

Manufacturers use advanced techniques like chemical vapor deposition (CVD) or thermal spraying to apply SiC coatings. These methods ensure uniformity and precision. The process involves depositing silicon carbide onto a substrate, creating a durable and protective layer tailored to specific industrial needs.

Are ceramic custom SiC coatings environmentally friendly?

Yes, many manufacturers are developing eco-friendly SiC coatings. They use bio-based or recycled materials to reduce environmental impact. These coatings also extend the lifespan of components, minimizing waste and lowering the carbon footprint of industrial processes.

What industries benefit the most from ceramic custom SiC coatings?

Industries like aerospace, semiconductors, and renewable energy benefit significantly. SiC coatings enhance the durability of turbine blades, protect semiconductor equipment, and improve energy efficiency in power systems. Emerging applications include optical systems and space exploration.

How do SiC coatings improve cost-effectiveness?

SiC coatings reduce maintenance costs by extending the lifespan of components. For example, they lower blade replacement frequency by 40% compared to alumina alternatives. Their durability and resistance to wear minimize downtime, making them a cost-effective solution for high-stress environments.