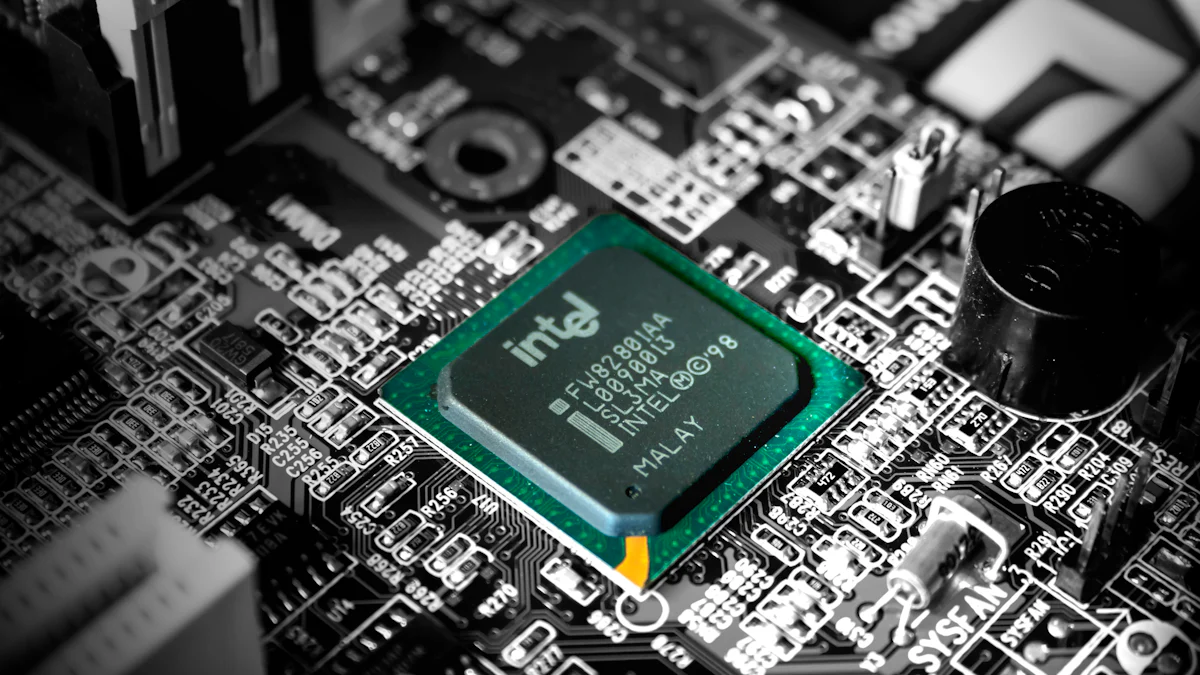

I’ve noticed that silicon carbide coated susceptors play a vital role in industries like semiconductor manufacturing and aerospace. The sic coating provides excellent thermal conductivity and chemical resistance, making these sic coated susceptors essential for high-purity processes. However, they face several challenges. Durability issues arise from coating degradation and environmental exposure. Thermal performance inconsistencies, such as uneven heat distribution, can lead to mechanical stress. Contamination risks, including material shedding, threaten the integrity of operations. High manufacturing costs and limited application compatibility further complicate their use. Addressing these concerns is essential for industries relying on silicon carbide coated susceptors to maintain operational excellence.

Key Takeaways

- Silicon carbide coated susceptors are important in making semiconductors. They work well because they handle heat and resist chemicals.

- Problems happen when the coating wears off, heats up, or meets chemicals. This can make them last shorter and work less well.

- Pieces breaking off can cause contamination, which can ruin delicate work. Checking and fixing them often is very important.

- They cost a lot to make and don’t fit all uses. This can stop people from using them, even though they work great in many cases.

- New materials and ideas might fix these problems. These changes could make susceptors more useful and better for different industries.

Durability Challenges

Coating Degradation

Causes of Wear and Tear

I’ve observed that silicon carbide coated susceptors face wear and tear due to several factors. One major cause is mechanical abrasion during repeated use. Over time, even the toughest coatings can develop micro-cracks. These cracks weaken the surface and make it more prone to damage. Another issue comes from temperature fluctuations. When susceptors heat up and cool down repeatedly, the coating expands and contracts. This constant movement stresses the material, leading to gradual degradation.

Impact of Corrosion from Residual Gases

Residual gases in industrial environments also play a role in coating degradation. For example, gases like oxygen or water vapor can react with the silicon carbide layer. This reaction causes oxidation, which eats away at the coating. In some cases, corrosive gases like chlorine or ammonia accelerate this process. Once the coating starts to break down, the underlying material becomes exposed. This exposure reduces the susceptor’s lifespan and reliability.

Environmental Resistance

Effects of Thermal Cycling

Thermal cycling is another challenge I’ve noticed with silicon carbide coated susceptors. These materials often operate in high-temperature environments, where they must endure rapid heating and cooling. While silicon carbide offers excellent thermal stability, repeated cycles can still cause stress. Over time, this stress leads to cracks or delamination of the coating. These issues compromise the susceptor’s ability to perform consistently.

Chemical Exposure Vulnerabilities

Chemical exposure is another factor that tests the durability of these susceptors. Silicon carbide coatings are highly resistant to many chemicals, which is why they’re widely used. However, in harsh environments, even this robust material can face challenges. Aggressive agents like strong acids or alkalis can slowly erode the coating. This erosion reduces its protective properties, leaving the susceptor vulnerable to further damage.

Silicon carbide coated susceptors excel in durability because of their resistance to corrosion, oxidation, and wear. Their chemical inertness prevents reactions with aggressive agents, while their thermal stability allows them to withstand high temperatures. However, these benefits don’t make them immune to long-term environmental stressors.

Thermal Performance Issues

Heat Distribution Problems

Uneven Thermal Expansion

I’ve noticed that uneven thermal expansion can create significant challenges for silicon carbide coated susceptors. When exposed to high temperatures, the coating and the underlying material expand at different rates. This mismatch leads to internal stress. Over time, this stress can cause warping or deformation, which affects the susceptor’s ability to distribute heat evenly. In precision-driven industries like semiconductor manufacturing, even minor inconsistencies in heat distribution can disrupt the entire process.

Mechanical Stress and Cracking

Mechanical stress is another issue I’ve observed. As susceptors undergo repeated heating and cooling cycles, the constant expansion and contraction weaken the material. This process often results in cracking. Once cracks form, they compromise the structural integrity of the susceptor. These cracks also create pathways for contaminants, further reducing the susceptor’s performance. Maintaining consistent thermal performance becomes increasingly difficult as these issues progress.

Efficiency Limitations

Energy Loss in High-Temperature Applications

Silicon carbide coated susceptors face efficiency limitations in high-temperature applications. I’ve seen how their flat design can struggle to meet the demands of high-throughput processes. Barrel-type designs, for example, often perform better in such scenarios. Additionally, compatibility issues with certain reactor designs can limit their use in diverse production setups. While these susceptors excel in many areas, these limitations can hinder their overall efficiency.

- Key factors contributing to energy loss include:

- Higher initial manufacturing costs due to advanced materials.

- Design limitations that reduce adaptability in specific applications.

Comparison with Alternative Materials

Compared to traditional materials like graphite and quartz, silicon carbide coated susceptors offer superior thermal efficiency. Their excellent thermal conductivity ensures uniform heat distribution, which is critical for processes requiring precision. I’ve found that these susceptors can withstand extreme temperatures without degrading, making them ideal for high-temperature environments. They also allow for higher processing temperatures, which improves yield in semiconductor fabrication. However, while they outperform alternatives in many ways, their higher cost and specific design requirements can make them less practical for some applications.

Contamination Risks

Material Shedding

Sources of Particle Contamination

I’ve noticed that material shedding can be a significant issue with silicon carbide coated susceptors. Over time, the coating may release tiny particles due to mechanical stress or surface wear. These particles often come from micro-cracks or areas where the coating has degraded. High-temperature environments and repeated thermal cycling can accelerate this process. Even small amounts of shedding can introduce contaminants into sensitive systems, especially in industries like semiconductor manufacturing.

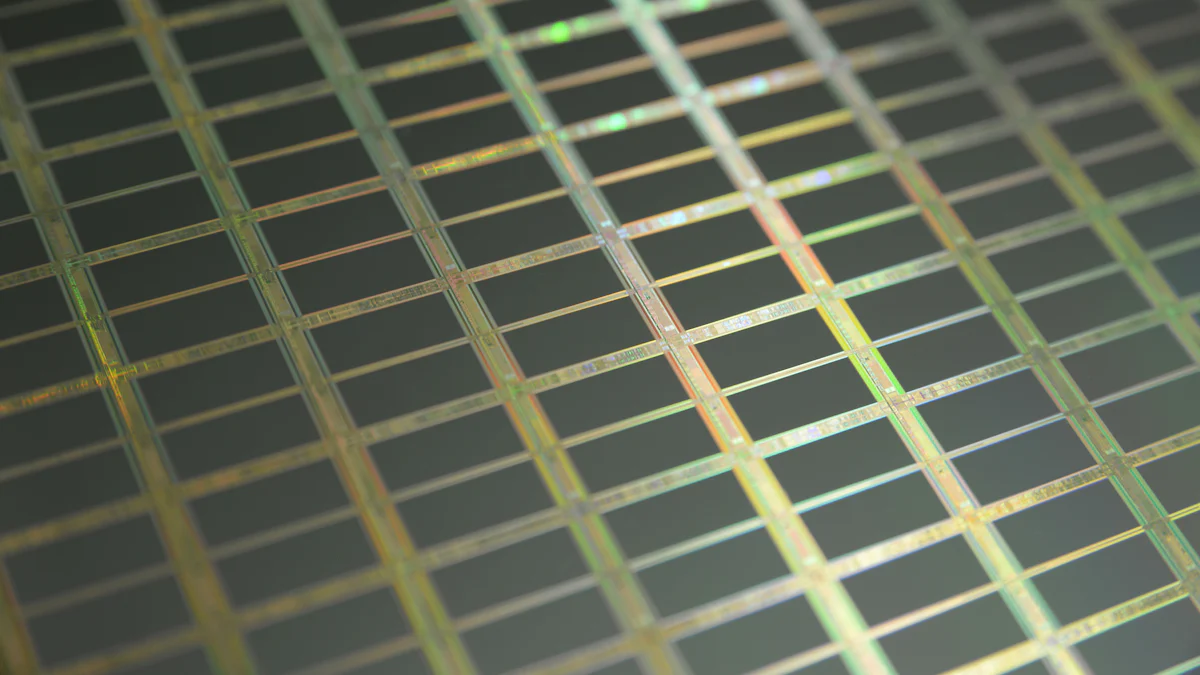

Impact on Semiconductor and Photovoltaic Processes

Particle contamination poses a serious risk to semiconductor and photovoltaic processes. I’ve seen how even a single particle can disrupt the production of wafers or solar cells. These industries require ultra-clean environments to maintain product quality. Contaminants can cause defects in thin films or interfere with the deposition of materials. This leads to lower yields and higher production costs. Preventing material shedding is critical to ensuring consistent performance and reliability in these applications.

Chemical Reactivity

Corrosion from Ammonia and Chlorine Exposure

Silicon carbide coated susceptors face challenges when exposed to aggressive chemicals like ammonia and chlorine. These substances can corrode the coating over time, especially in high-temperature settings. I’ve observed that prolonged exposure to such chemicals weakens the protective layer, making the susceptor more vulnerable to damage. This corrosion not only shortens the lifespan of the susceptor but also increases the risk of contamination in critical processes.

Strategies to Minimize Contamination

To minimize contamination risks, I recommend using silicon carbide coatings due to their exceptional chemical resistance. These coatings prevent reactions with aggressive agents like acids, alkalis, and salts. Their non-reactive nature ensures that they remain stable even in harsh environments. This stability enhances the durability of susceptors and reduces the likelihood of contamination. Regular maintenance and monitoring can also help identify early signs of wear or corrosion. By addressing these issues promptly, industries can maintain the reliability of their systems and protect their processes from contamination.

Cost-Effectiveness Concerns

High Manufacturing Costs

Complexity of SiC Coating Processes

I’ve noticed that the process of creating silicon carbide coated susceptors involves advanced techniques. These methods require precision and specialized equipment. For example, chemical vapor deposition (CVD) is often used to apply the silicon carbide layer. This process ensures a uniform coating but takes time and resources. The equipment itself is expensive, and maintaining it adds to the overall cost. Additionally, the need for skilled technicians to operate these systems further increases expenses.

Long-Term Maintenance Expenses

Maintenance costs also play a significant role in the overall expense of silicon carbide coated susceptors. Over time, the coating may degrade due to wear or exposure to harsh environments. Regular inspections and repairs are necessary to ensure optimal performance. I’ve seen how industries must invest in replacement parts or refurbishing services to extend the lifespan of these susceptors. While these measures help maintain reliability, they add to the long-term financial burden.

Value Comparison

Cost-Benefit Analysis of Alternatives

When comparing silicon carbide coated susceptors to other materials, I’ve found several advantages:

- They offer superior thermal stability, enabling higher processing temperatures. This leads to better yields in semiconductor fabrication.

- Their excellent chemical resistance makes them ideal for processes like MOCVD, where reactive gases are involved.

- Traditional materials like graphite and quartz have limitations. Graphite provides good thermal conductivity but lacks chemical resistance. Quartz, on the other hand, has great thermal stability but is mechanically weaker.

These benefits make silicon carbide coated susceptors a valuable choice despite their higher costs.

Scenarios Favoring Silicon Carbide Coated Susceptors

Certain applications highlight the advantages of silicon carbide coated susceptors. For example, they excel in MOCVD processes due to their ability to withstand harsh conditions. They are also essential for achieving high-quality epitaxy in semiconductor devices. Here’s a comparison of materials and their applications:

| Material | Advantages | Applications |

|---|---|---|

| Silicon Carbide | Exceptional thermal conductivity, unmatched durability, remarkable chemical stability | Semiconductor manufacturing, MOCVD |

| Graphite | Excels in thermal management | Various thermal applications |

| Molybdenum | Unique benefits in specific high-temperature environments | High-temperature applications |

This table shows why silicon carbide coated susceptors remain the preferred choice for industries requiring precision and durability.

Application Limitations

Process Incompatibilities

Examples of Unsuitable Industrial Applications

I’ve noticed that silicon carbide coated susceptors don’t work well in every industrial setting. For instance, industries requiring extremely lightweight materials may find these susceptors too dense. Aerospace applications often demand components with minimal weight, where alternatives like graphite perform better. Additionally, processes involving highly corrosive chemicals, such as hydrofluoric acid, can degrade the coating over time. This makes silicon carbide less ideal for such environments.

Challenges in Adapting to Diverse Needs

Adapting silicon carbide coated susceptors to meet diverse industrial requirements can be challenging. Some industries need susceptors with unique shapes or sizes, but silicon carbide’s rigidity limits customization. I’ve also seen how certain manufacturing setups require materials with higher flexibility or lower thermal mass. These demands often push industries to explore other options. While silicon carbide excels in many areas, its limitations in adaptability can restrict its use in specialized applications.

Emerging Alternatives

Innovations in Susceptor Materials

I’ve observed exciting developments in alternative materials for susceptors. Graphite stands out as a cost-effective option for general-purpose applications. It’s lightweight and transfers heat efficiently. Coated graphite offers improved chemical resistance, making it suitable for moderately reactive environments. Molybdenum is another alternative that addresses specific needs. Its mechanical strength makes it ideal for applications requiring stability under heavy loads. However, it has lower thermal conductivity and limited chemical resistance compared to silicon carbide or coated graphite.

Potential for Improved Designs

Emerging materials inspire new designs that could overcome current limitations. For example, hybrid susceptors combining silicon carbide with other materials might offer better flexibility and reduced weight. I’ve also seen research into advanced coatings that enhance chemical resistance without compromising thermal performance. These innovations could lead to susceptors that adapt more easily to diverse industrial needs. As industries evolve, I believe these advancements will play a crucial role in shaping the future of susceptor technology.

I’ve explored the main challenges with silicon carbide coated susceptors, including durability, thermal performance, contamination, cost, and application limitations. These issues can significantly impact industries relying on these materials. Evaluating these factors helps businesses make informed decisions and optimize their processes. I believe further research and innovation are essential to overcome these challenges. Advancements in material science could improve susceptor performance, making them more reliable and versatile for future applications.

FAQ

What are silicon carbide coated susceptors used for?

Silicon carbide coated susceptors are essential in industries like semiconductor manufacturing and photovoltaics. I’ve seen them used to support wafers during high-temperature processes. Their excellent thermal conductivity and chemical resistance make them ideal for precise and clean operations.

How do silicon carbide coated susceptors improve thermal performance?

These susceptors distribute heat evenly and withstand extreme temperatures. I’ve noticed their thermal stability helps maintain consistent processing conditions. This ensures better product quality in applications like epitaxy and chemical vapor deposition.

Can silicon carbide coated susceptors resist chemical damage?

Yes, they resist many chemicals, including acids and alkalis. However, I’ve observed that prolonged exposure to aggressive agents like ammonia or chlorine can weaken the coating. Regular maintenance helps prevent damage and extends their lifespan.

Are silicon carbide coated susceptors cost-effective?

While they have higher upfront costs, I believe their durability and performance justify the investment. They reduce downtime and improve yields in precision-driven industries. For long-term use, they often prove more economical than alternatives.

What are the limitations of silicon carbide coated susceptors?

I’ve found that their rigidity limits customization for unique shapes or sizes. They may not suit lightweight applications or environments with highly corrosive chemicals. Exploring alternatives can help address these specific needs.