Ceramic materials play a critical role in modern industries, but their properties vary significantly. Understanding these differences helps engineers and designers select the right material for specific applications. Silicon carbide ceramic stands out due to its exceptional hardness, thermal conductivity, and chemical resistance. These qualities make it ideal for demanding environments, such as those requiring carbide coatings or tic coating for enhanced durability. Comparing silicon carbide ceramic with other materials reveals its unique advantages, enabling informed decisions for applications in aerospace, automotive, and beyond.

Key Takeaways

- Silicon carbide ceramic is very hard. It resists wear better than alumina, zirconia, and silicon nitride. This is important for mining and machining industries.

- Silicon carbide ceramic is lightweight. This makes it great for airplanes and cars. Lighter materials help improve performance.

- Silicon carbide ceramic moves heat well. It works in electronics and systems needing good heat control.

- It resists chemicals better than most materials. This makes it last longer in tough environments like chemical factories.

- When choosing materials, think about the job it will do. Look at cost, how it works, and the environment to get the best results.

Physical and Mechanical Properties

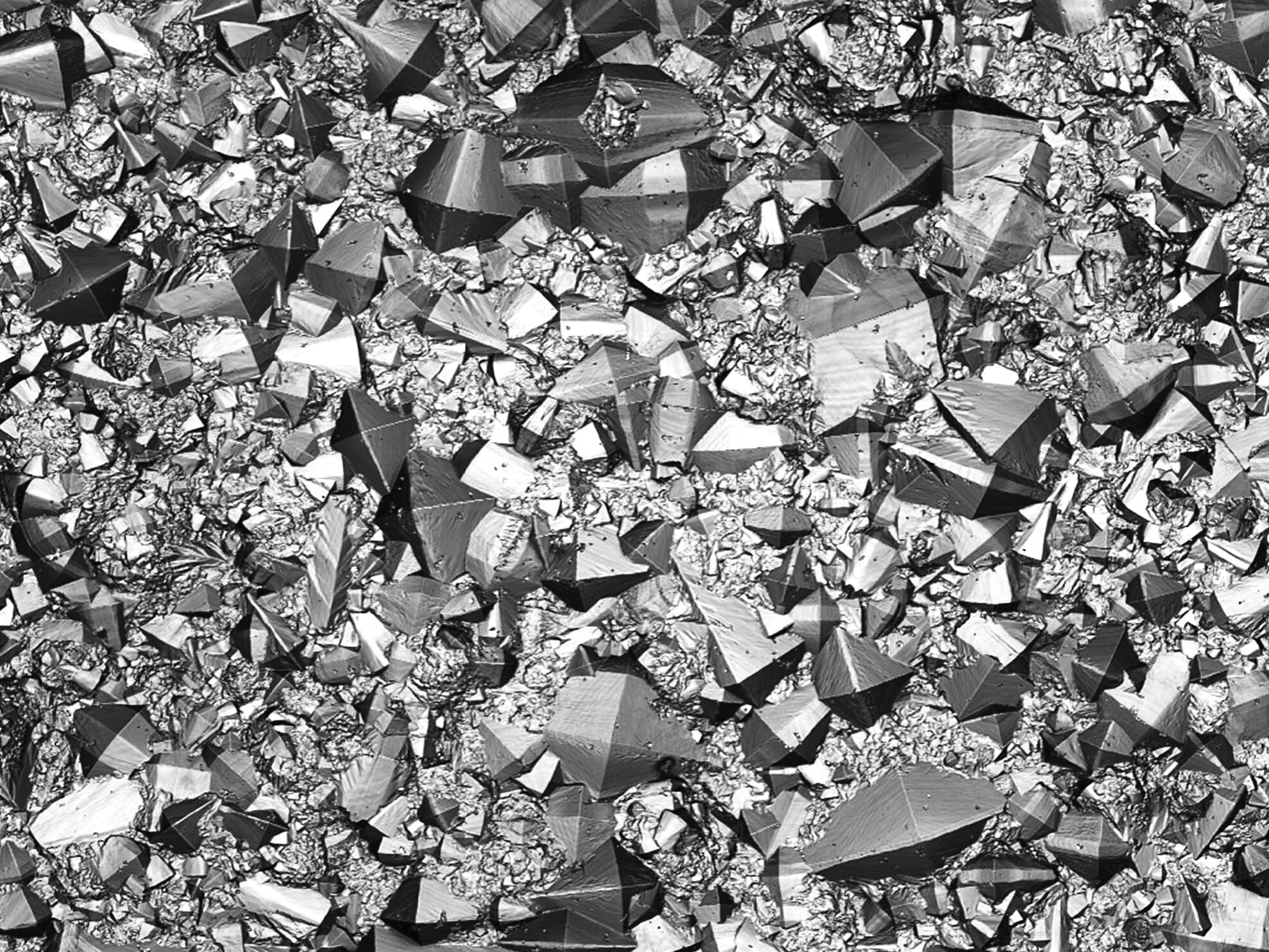

Hardness and Wear Resistance

Silicon carbide ceramic vs alumina

Silicon carbide ceramic exhibits superior hardness compared to alumina. This makes it more resistant to wear in abrasive environments. Alumina, while durable, tends to wear down faster under high-friction conditions. Industries requiring extreme durability, such as mining or machining, often prefer silicon carbide ceramic for its longer lifespan.

Silicon carbide ceramic vs zirconia

Zirconia offers excellent toughness but falls short in hardness when compared to silicon carbide ceramic. Silicon carbide ceramic resists surface scratches and deformation more effectively. This property makes it ideal for applications like cutting tools, where maintaining a sharp edge is critical.

Silicon carbide ceramic vs silicon nitride

Silicon nitride provides good wear resistance but does not match the hardness of silicon carbide ceramic. Silicon carbide ceramic performs better in environments with constant abrasive forces. For example, it is often used in sandblasting nozzles, where wear resistance is crucial.

Mechanical Strength and Toughness

Silicon carbide ceramic vs alumina

Silicon carbide ceramic demonstrates higher mechanical strength than alumina. However, alumina offers better fracture toughness, making it less likely to crack under sudden impacts. Applications requiring high load-bearing capacity often favor silicon carbide ceramic.

Silicon carbide ceramic vs zirconia

Zirconia surpasses silicon carbide ceramic in toughness, allowing it to withstand impacts more effectively. However, silicon carbide ceramic excels in strength, making it suitable for static loads in high-pressure environments.

Silicon carbide ceramic vs silicon nitride

Silicon nitride combines strength and toughness effectively, but silicon carbide ceramic outperforms it in terms of overall strength. This makes silicon carbide ceramic a better choice for structural components under heavy loads.

Density and Weight

Silicon carbide ceramic vs alumina

Silicon carbide ceramic is lighter than alumina, which makes it advantageous in weight-sensitive applications. Alumina’s higher density can be a drawback in industries like aerospace, where reducing weight is critical.

Silicon carbide ceramic vs zirconia

Zirconia is significantly denser than silicon carbide ceramic. This difference makes silicon carbide ceramic a preferred material for lightweight designs, such as in automotive components.

Silicon carbide ceramic vs silicon nitride

Silicon carbide ceramic and silicon nitride have comparable densities, but silicon carbide ceramic often edges out in applications requiring a balance of weight and strength. Its lightweight nature contributes to its popularity in advanced engineering fields.

Thermal Properties

Thermal Conductivity

Silicon carbide ceramic vs alumina

Silicon carbide ceramic exhibits significantly higher thermal conductivity than alumina. This property allows it to transfer heat more efficiently, making it ideal for heat exchangers and thermal management systems. Alumina, while a good insulator, cannot match the heat dissipation capabilities of silicon carbide ceramic.

Silicon carbide ceramic vs zirconia

Zirconia has relatively low thermal conductivity compared to silicon carbide ceramic. This makes zirconia better suited for applications requiring thermal insulation. In contrast, silicon carbide ceramic excels in environments where rapid heat transfer is essential, such as in high-performance electronics.

Silicon carbide ceramic vs silicon nitride

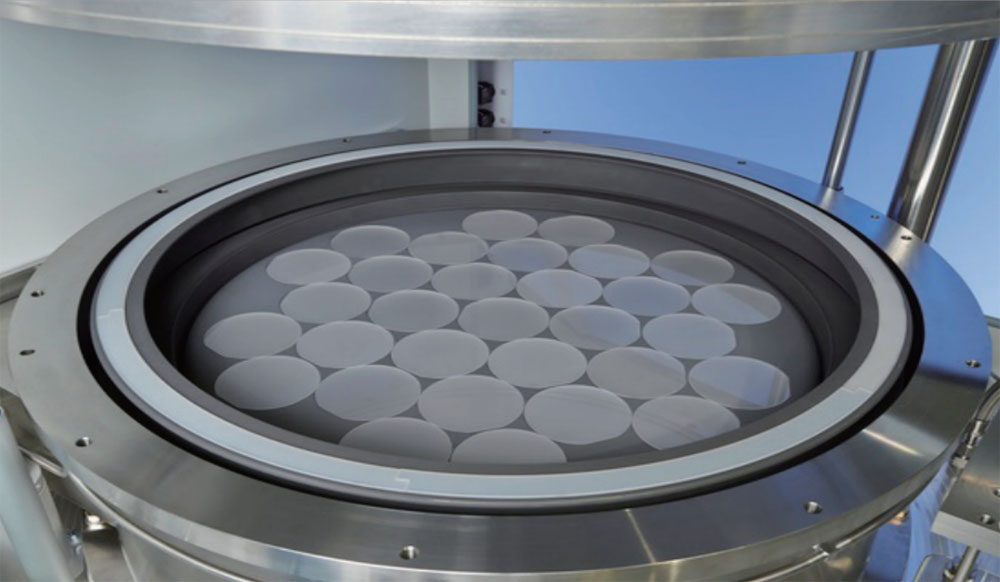

Silicon nitride offers moderate thermal conductivity but falls short of silicon carbide ceramic. Silicon carbide ceramic’s superior heat transfer properties make it a preferred choice for applications like semiconductor manufacturing, where precise thermal control is critical.

Thermal Shock Resistance

Silicon carbide ceramic vs alumina

Silicon carbide ceramic outperforms alumina in thermal shock resistance. It can withstand rapid temperature changes without cracking, making it suitable for applications like furnace linings. Alumina, on the other hand, is more prone to thermal stress under similar conditions.

Silicon carbide ceramic vs zirconia

Zirconia demonstrates excellent thermal shock resistance due to its toughness, but silicon carbide ceramic still holds an edge in extreme environments. Its ability to endure sudden temperature fluctuations makes it a reliable material for high-temperature industrial processes.

Silicon carbide ceramic vs silicon nitride

Silicon nitride offers good thermal shock resistance, but silicon carbide ceramic surpasses it in extreme conditions. This advantage makes silicon carbide ceramic a top choice for applications like gas turbines, where materials face rapid heating and cooling cycles.

High-Temperature Performance

Silicon carbide ceramic vs alumina

Silicon carbide ceramic maintains its structural integrity at much higher temperatures than alumina. This makes it ideal for applications like high-temperature kilns and reactors. Alumina, while heat-resistant, begins to degrade at lower temperatures.

Silicon carbide ceramic vs zirconia

Zirconia performs well at elevated temperatures but cannot match the stability of silicon carbide ceramic. Silicon carbide ceramic’s ability to retain strength and resist oxidation at extreme temperatures makes it a superior choice for aerospace components.

Silicon carbide ceramic vs silicon nitride

Silicon nitride exhibits excellent high-temperature performance, but silicon carbide ceramic often surpasses it in terms of thermal stability and oxidation resistance. This makes silicon carbide ceramic a preferred material for applications like heat shields and engine components.

Chemical Properties

Chemical Inertness

Silicon carbide ceramic vs alumina

Silicon carbide ceramic exhibits greater chemical inertness than alumina. It resists reactions with acids and alkalis, even under extreme conditions. Alumina, while chemically stable, can degrade when exposed to strong acids or bases. This makes silicon carbide ceramic a better choice for chemical processing equipment.

Silicon carbide ceramic vs zirconia

Zirconia offers good chemical stability but cannot match the inertness of silicon carbide ceramic. Silicon carbide ceramic remains unreactive in highly corrosive environments, such as those involving hydrofluoric acid. Zirconia may experience surface degradation in similar conditions.

Silicon carbide ceramic vs silicon nitride

Silicon nitride demonstrates moderate chemical inertness but falls short of silicon carbide ceramic. Silicon carbide ceramic withstands exposure to aggressive chemicals without compromising its structural integrity. This makes it ideal for applications like chemical seals and pump components.

Corrosion Resistance

Silicon carbide ceramic vs alumina

Silicon carbide ceramic provides superior corrosion resistance compared to alumina. It resists oxidation and chemical attack in both acidic and alkaline environments. Alumina, though resistant to mild corrosion, can deteriorate in highly corrosive settings.

Silicon carbide ceramic vs zirconia

Zirconia performs well in mildly corrosive environments but lacks the robustness of silicon carbide ceramic. Silicon carbide ceramic endures prolonged exposure to harsh chemicals, making it suitable for industrial reactors and pipelines.

Silicon carbide ceramic vs silicon nitride

Silicon nitride offers decent corrosion resistance but cannot rival silicon carbide ceramic. Silicon carbide ceramic excels in environments with high moisture or chemical exposure, ensuring long-term durability.

Oxidation Resistance

Silicon carbide ceramic vs alumina

Silicon carbide ceramic outperforms alumina in oxidation resistance. It forms a protective oxide layer at high temperatures, preventing further degradation. Alumina, while resistant to oxidation, may weaken under prolonged exposure to extreme heat.

Silicon carbide ceramic vs zirconia

Zirconia resists oxidation effectively but cannot match the high-temperature stability of silicon carbide ceramic. Silicon carbide ceramic maintains its properties even in oxygen-rich environments, making it ideal for furnace components.

Silicon carbide ceramic vs silicon nitride

Silicon nitride offers good oxidation resistance but falls behind silicon carbide ceramic. Silicon carbide ceramic withstands oxidation at higher temperatures, ensuring reliability in demanding applications like gas turbines.

Cost and Processing Considerations

Material Costs

Silicon carbide ceramic vs alumina

Silicon carbide ceramic generally costs more than alumina. Its higher price stems from the advanced manufacturing processes and raw materials required. Alumina, being more abundant and easier to process, is often chosen for cost-sensitive applications. However, industries prioritize silicon carbide ceramic when performance outweighs cost considerations.

Silicon carbide ceramic vs zirconia

Zirconia is typically more expensive than silicon carbide ceramic. The high cost of zirconia arises from its complex production methods and limited availability. Silicon carbide ceramic offers a cost-effective alternative for applications requiring high strength and thermal conductivity.

Silicon carbide ceramic vs silicon nitride

Silicon nitride and silicon carbide ceramic have comparable costs. Both materials involve intricate manufacturing techniques, which contribute to their pricing. However, silicon carbide ceramic often provides better value in applications demanding superior hardness and thermal properties.

Manufacturing Challenges

Silicon carbide ceramic vs alumina

Producing silicon carbide ceramic involves more challenges than alumina. Its high melting point and hardness require specialized equipment and techniques. Alumina, on the other hand, is easier to shape and sinter, making it more accessible for large-scale production.

Silicon carbide ceramic vs zirconia

Zirconia’s manufacturing process is complex due to its sensitivity to temperature and phase changes. Silicon carbide ceramic, while also challenging to produce, benefits from more established production methods. This makes it slightly easier to manufacture in consistent quality.

Silicon carbide ceramic vs silicon nitride

Both silicon carbide ceramic and silicon nitride present significant manufacturing challenges. Silicon carbide ceramic requires precise control during sintering to achieve its desired properties. Silicon nitride, however, demands even more stringent conditions, such as high-pressure sintering, which increases production complexity.

Scalability and Availability

Silicon carbide ceramic vs alumina

Silicon carbide ceramic is less scalable than alumina due to its demanding production requirements. Alumina benefits from widespread availability and simpler processing, making it easier to scale for mass production.

Silicon carbide ceramic vs zirconia

Zirconia’s limited raw material sources and complex processing hinder its scalability. Silicon carbide ceramic, while also resource-intensive, has a more established supply chain, allowing for better scalability in industrial applications.

Silicon carbide ceramic vs silicon nitride

Silicon carbide ceramic and silicon nitride face similar scalability challenges. Both materials rely on advanced manufacturing techniques, which limit their availability. However, silicon carbide ceramic’s broader industrial use has led to slightly better scalability compared to silicon nitride.

Application-Specific Advantages and Limitations

Industrial Applications

Silicon carbide ceramic vs alumina

Silicon carbide ceramic offers better wear resistance and thermal stability than alumina in industrial applications. It performs well in abrasive environments, such as mining and machining, where durability is critical. Alumina, while cost-effective, lacks the same level of hardness and thermal conductivity. Industries often choose silicon carbide ceramic for components like pump seals and nozzles that face harsh conditions.

Silicon carbide ceramic vs zirconia

Zirconia provides excellent toughness but falls short in hardness and thermal conductivity compared to silicon carbide ceramic. This makes zirconia suitable for applications requiring impact resistance, such as grinding media. However, silicon carbide ceramic excels in high-temperature industrial processes, including heat exchangers and furnace linings, due to its superior thermal properties.

Silicon carbide ceramic vs silicon nitride

Silicon nitride combines strength and toughness effectively, making it a good choice for industrial bearings and cutting tools. However, silicon carbide ceramic surpasses it in wear resistance and chemical stability. This advantage makes silicon carbide ceramic ideal for applications like chemical processing equipment and sandblasting nozzles.

Aerospace and Automotive Applications

Silicon carbide ceramic vs alumina

Silicon carbide ceramic’s lightweight nature and high-temperature performance make it a preferred material in aerospace and automotive industries. Alumina, being denser, adds unnecessary weight to components like brake discs and engine parts. Silicon carbide ceramic also resists thermal shock better, ensuring reliability in extreme conditions.

Silicon carbide ceramic vs zirconia

Zirconia’s toughness makes it suitable for impact-resistant components, such as crash-resistant parts in vehicles. However, silicon carbide ceramic outperforms zirconia in thermal conductivity and oxidation resistance. These properties make it ideal for aerospace heat shields and automotive exhaust systems.

Silicon carbide ceramic vs silicon nitride

Silicon nitride offers excellent thermal shock resistance, making it a strong contender in aerospace and automotive applications. However, silicon carbide ceramic provides better thermal conductivity and wear resistance. This makes it a superior choice for high-performance engine components and turbine blades.

Medical and Electronic Applications

Silicon carbide ceramic vs alumina

Silicon carbide ceramic’s chemical inertness and thermal conductivity make it suitable for medical implants and electronic substrates. Alumina, while biocompatible, lacks the same level of thermal performance. Silicon carbide ceramic also ensures better heat dissipation in electronic devices, enhancing their efficiency.

Silicon carbide ceramic vs zirconia

Zirconia’s biocompatibility makes it a popular choice for dental implants and joint replacements. However, silicon carbide ceramic offers better chemical stability and thermal conductivity, making it ideal for electronic applications like power modules and semiconductors.

Silicon carbide ceramic vs silicon nitride

Silicon nitride performs well in medical and electronic applications due to its strength and biocompatibility. However, silicon carbide ceramic surpasses it in thermal conductivity and chemical resistance. This makes it a preferred material for advanced medical devices and high-performance electronic components.

Silicon carbide ceramic stands out among other ceramic materials due to its exceptional hardness, thermal conductivity, and chemical resistance. These properties make it ideal for demanding applications in industries like aerospace, automotive, and electronics. While other ceramics offer specific advantages, silicon carbide ceramic provides a unique combination of strength, durability, and thermal stability. Selecting the right material depends on the application’s requirements, such as cost, performance, and environmental conditions. Engineers and designers should evaluate these factors carefully to ensure optimal results.

FAQ

What makes silicon carbide ceramic unique compared to other ceramics?

Silicon carbide ceramic stands out due to its exceptional hardness, thermal conductivity, and chemical resistance. These properties make it ideal for demanding applications, such as high-temperature environments, abrasive conditions, and chemically aggressive settings.

Is silicon carbide ceramic suitable for lightweight applications?

Yes, silicon carbide ceramic is lightweight compared to many other ceramics, such as alumina and zirconia. Its low density makes it a preferred choice for aerospace and automotive components where weight reduction is critical.

How does silicon carbide ceramic handle extreme temperatures?

Silicon carbide ceramic maintains its strength and stability at very high temperatures. It resists thermal shock and oxidation, making it suitable for applications like gas turbines, heat exchangers, and furnace linings.

Are there any limitations to using silicon carbide ceramic?

Silicon carbide ceramic can be expensive and challenging to manufacture. Its brittleness may also limit its use in applications requiring high impact resistance. However, its performance often outweighs these drawbacks in specialized applications.

Which industries benefit the most from silicon carbide ceramic?

Industries like aerospace, automotive, electronics, and chemical processing benefit significantly. Its durability, thermal stability, and chemical inertness make it ideal for components like engine parts, heat shields, and chemical seals.

Tip: When selecting a ceramic material, always consider the specific application requirements, including cost, performance, and environmental conditions.