You might not realize it, but silicon carbide coating on graphite components is shaping the future of advanced technologies in 2025. This coating improves material performance in extreme environments, making it invaluable for industries requiring high durability and thermal stability. With its impressive silicon carbide density, this innovation withstands high temperatures and corrosive conditions. The applications of silicon carbide coating extend to semiconductors, solar energy, and aerospace, where its unique properties unlock new possibilities. These advancements demonstrate the incredible potential of silicon carbide uses in cutting-edge fields.

Key Takeaways

- Silicon carbide coating makes graphite parts stronger and last longer. It protects them from damage, lowers repair costs, and helps machines work better.

- This coating handles heat well and carries heat easily. It works great in hot places like making computer chips or solar panels.

- The coating stops rust and damage from air, so parts last longer. This is very important for factories in tough conditions.

- Using graphite parts with this coating saves money. It reduces the need for new parts and uses less energy, helping the planet.

- New inventions in 2025, like super-fast computers and electric cars, use this coating. It helps make cool ideas happen in many industries.

Key Benefits of Silicon Carbide Coating on Graphite Components

Enhanced Durability and Wear Resistance

You rely on materials that can withstand wear and tear in demanding environments. Silicon carbide coating on graphite components provides unmatched durability. Its hardness protects graphite surfaces from scratches, abrasions, and mechanical damage. This feature is especially valuable in industries where components face constant friction or impact.

Tip: When durability improves, maintenance costs decrease, and operational efficiency increases.

The coating acts as a shield, extending the lifespan of graphite components. You can count on this technology to reduce downtime and improve reliability in critical applications.

Superior Thermal Stability and Conductivity

High temperatures often compromise material performance. Silicon carbide coating on graphite components excels in thermal stability, allowing you to use it in extreme heat without degradation. This property is crucial for applications like semiconductor manufacturing, where precision and consistency matter.

The coating also enhances thermal conductivity. Heat transfers efficiently, ensuring optimal performance in processes requiring rapid temperature changes. For example, in solar energy systems, this feature boosts energy conversion rates.

Note: Materials with superior thermal properties contribute to energy efficiency and sustainability.

Exceptional Corrosion and Oxidation Resistance

Corrosive environments can weaken materials over time. Silicon carbide coating on graphite components resists chemical attacks, making it ideal for industries exposed to harsh conditions. Whether it's acidic solutions or oxidizing atmospheres, the coating maintains its integrity.

This resistance ensures that your components last longer and perform reliably. In aerospace applications, where exposure to extreme conditions is common, this benefit is indispensable.

Callout: Corrosion resistance not only extends the lifespan of components but also reduces environmental impact by minimizing waste.

Extended Lifespan and Cost Efficiency

When you invest in advanced materials, you expect them to last longer and perform better. Silicon carbide coating on graphite components delivers on both fronts. This coating significantly extends the lifespan of graphite parts by protecting them from wear, corrosion, and thermal degradation. As a result, you can rely on these components for prolonged use in demanding environments.

One of the key advantages lies in its ability to reduce maintenance and replacement costs. Frequent repairs or replacements can disrupt operations and inflate expenses. With silicon carbide coating, you minimize these interruptions. For example:

- In semiconductor manufacturing, coated graphite components maintain their integrity during repeated high-temperature cycles.

- In solar energy systems, they resist environmental wear, ensuring consistent performance over time.

Tip: Longer-lasting components mean fewer replacements, which translates to lower operational costs and higher productivity.

The cost efficiency of this technology goes beyond durability. It also enhances energy efficiency. The superior thermal conductivity of silicon carbide coating ensures optimal heat transfer, reducing energy waste. This feature is especially valuable in industries where energy consumption directly impacts profitability. By choosing coated graphite components, you not only save on material costs but also improve overall system efficiency.

Moreover, the extended lifespan of these components contributes to sustainability. Fewer replacements mean less waste, aligning with eco-friendly practices. This makes silicon carbide coating a smart choice for industries aiming to reduce their environmental footprint.

Callout: Investing in durable materials like silicon carbide-coated graphite is not just cost-effective; it’s a step toward sustainable innovation.

Applications of Silicon Carbide Coating on Graphite Components in Advanced Industries

Semiconductor Manufacturing and LED Production

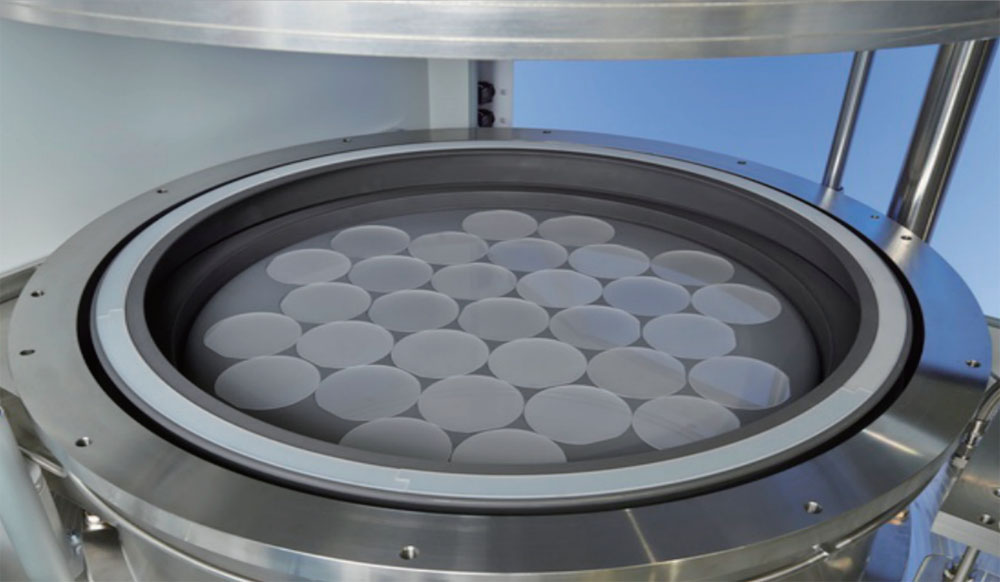

In semiconductor manufacturing, precision and reliability are critical. You need materials that can endure high temperatures and maintain stability during intricate processes. Silicon carbide coating on graphite components plays a vital role here. It protects graphite susceptors and wafer carriers from wear and oxidation during repeated thermal cycles. This ensures consistent performance and reduces the risk of contamination in cleanroom environments.

LED production also benefits from this technology. The coating enhances the thermal conductivity of graphite components, allowing efficient heat dissipation during the fabrication of LED chips. This improves production efficiency and ensures the quality of the final product.

Tip: Using coated graphite components in semiconductor and LED manufacturing minimizes defects and boosts productivity.

Photovoltaic Systems and Solar Energy Applications

Solar energy systems demand materials that can withstand harsh environmental conditions. Silicon carbide coating on graphite components offers exceptional resistance to corrosion and oxidation, making it ideal for photovoltaic applications. You can rely on these coated components to maintain their integrity even in extreme weather or high UV exposure.

In the production of solar cells, the coating ensures precise thermal management. It facilitates uniform heat distribution during the crystallization of silicon wafers, a critical step in photovoltaic manufacturing. This leads to higher energy conversion efficiency and improved durability of solar panels.

Callout: By enhancing the performance of solar energy systems, this technology supports the global shift toward renewable energy.

High-Temperature Industrial Processes

Industries like metallurgy and chemical processing often operate in extreme heat. You need materials that can endure these conditions without degrading. Silicon carbide coating on graphite components excels in such environments. It provides a protective barrier against thermal shock and chemical reactions, ensuring the longevity of critical equipment.

For example, in metal casting, coated graphite molds resist wear and maintain their shape under high temperatures. This results in more precise castings and reduced material waste. Similarly, in chemical reactors, the coating prevents corrosion from aggressive chemicals, ensuring safe and efficient operations.

Note: Investing in coated graphite components for high-temperature processes reduces downtime and enhances operational safety.

Aerospace and Space Technologies

You rely on materials that can perform under extreme conditions when designing aerospace and space technologies. Silicon carbide coating on graphite components offers the durability and thermal stability needed for these demanding applications. Spacecraft and satellites often face intense heat during atmospheric re-entry or prolonged exposure to solar radiation. The coating protects graphite components from thermal degradation, ensuring their reliability in these critical moments.

In rocket propulsion systems, the coating enhances the performance of graphite nozzles and thrust chambers. It resists wear caused by high-velocity exhaust gases and extreme temperatures. This ensures consistent thrust and reduces the risk of component failure during missions.

Tip: Using coated graphite components in propulsion systems improves efficiency and safety, which are vital for space exploration.

The coating also plays a role in lightweight design. Aerospace engineers prioritize materials that reduce weight without compromising strength. Silicon carbide-coated graphite components meet this requirement, enabling the development of fuel-efficient aircraft and spacecraft.

Applications extend to satellite technology. Coated graphite parts maintain their integrity in the vacuum of space, where exposure to radiation and temperature fluctuations is constant. This ensures uninterrupted operation of communication and observation systems.

Callout: By enhancing the performance of aerospace components, this technology supports the advancement of space exploration and satellite communication.

Emerging Technologies in 2025

You see the impact of silicon carbide coating on graphite components in emerging technologies that define 2025. Industries are leveraging this innovation to push the boundaries of what’s possible.

Quantum Computing

Quantum computing demands materials that can handle extreme precision and stability. Silicon carbide-coated graphite components provide the thermal management needed for quantum processors. They ensure consistent performance by dissipating heat efficiently, which is critical for maintaining quantum coherence.

Electric Vehicles (EVs)

The EV industry benefits from this coating in battery and motor technologies. Coated graphite components improve thermal conductivity, ensuring efficient heat management in high-performance batteries. This enhances battery lifespan and charging speed, addressing key challenges in EV adoption.

Advanced Robotics

Robotics systems require durable materials for high-stress applications. Silicon carbide coating protects graphite components in robotic joints and actuators, ensuring smooth operation and reducing wear. This enables robots to perform complex tasks with greater reliability.

Medical Devices

In medical technology, precision and durability are essential. Coated graphite components are used in high-temperature sterilization equipment and advanced imaging systems. Their resistance to corrosion and wear ensures consistent performance in critical healthcare applications.

Note: Emerging technologies rely on materials that combine durability, efficiency, and adaptability. Silicon carbide coating on graphite components meets these demands, driving innovation across industries.

Challenges and Solutions in Silicon Carbide Coating on Graphite Components

Overcoming Technical Challenges in Coating Application

Applying silicon carbide coating to graphite components requires precision. You face challenges like achieving uniform thickness and ensuring strong adhesion between the coating and the graphite substrate. These issues can lead to inconsistent performance or premature wear.

To overcome these challenges, manufacturers use advanced techniques like chemical vapor deposition (CVD) and plasma-enhanced processes. These methods allow precise control over coating thickness and ensure a strong bond. You can rely on these innovations to produce components with consistent quality and durability.

Tip: Regular testing and quality control during the coating process help identify and resolve issues early, ensuring reliable performance.

Addressing Cost and Scalability Concerns

Silicon carbide coating offers many benefits, but its production can be expensive. You might find that the cost of raw materials and specialized equipment limits its adoption in some industries. Scaling up production to meet growing demand also poses challenges.

Manufacturers are addressing these concerns by optimizing production processes. For example, they are developing cost-effective coating techniques and exploring alternative materials to reduce expenses. Automation plays a key role in scaling up production. By automating coating processes, you can achieve higher output while maintaining quality.

Callout: Investing in research and development helps lower costs and makes silicon carbide coating accessible to more industries.

Innovations in Material Compatibility and Coating Techniques

Material compatibility is crucial when applying silicon carbide coating. You need to ensure that the coating adheres well to graphite without causing structural damage. Some graphite grades may react differently during the coating process, leading to challenges in achieving uniform results.

Innovations in coating techniques are solving these issues. Manufacturers are experimenting with hybrid methods that combine CVD with other processes to enhance compatibility. They are also developing pre-treatment methods to prepare graphite surfaces for better adhesion.

Note: These advancements in coating technology ensure that silicon carbide-coated graphite components meet the demands of modern applications.

Future Developments in Coating Technology

The future of silicon carbide coating on graphite components looks promising. You can expect advancements that will make this technology even more efficient, accessible, and versatile. Researchers and manufacturers are focusing on several key areas to push the boundaries of what this coating can achieve.

1. Smarter Coating Processes

Emerging technologies like artificial intelligence (AI) and machine learning are transforming coating techniques. AI can optimize parameters like temperature, pressure, and deposition time during the coating process. This ensures consistent quality and reduces material waste. You’ll see smarter systems that adapt in real-time to produce flawless coatings.

Tip: Smarter processes mean fewer defects and lower production costs, making the technology more affordable for various industries.

2. Eco-Friendly Innovations

Sustainability is a growing priority. Future developments aim to reduce the environmental impact of silicon carbide coating. Researchers are exploring greener chemical vapor deposition (CVD) methods that use less energy and produce fewer emissions. You’ll also see a shift toward recyclable materials and eco-friendly production practices.

Callout: Eco-friendly innovations align with global efforts to reduce carbon footprints and promote sustainable manufacturing.

3. Enhanced Material Performance

Scientists are working to improve the properties of silicon carbide coatings. You can expect coatings with even higher thermal stability, better corrosion resistance, and improved wear performance. These enhancements will open doors to new applications in industries like nuclear energy and advanced robotics.

4. Customization for Emerging Needs

Future coating technologies will offer greater customization. You’ll be able to tailor coatings to meet specific requirements, such as unique shapes or extreme environmental conditions. This flexibility will make silicon carbide-coated graphite components indispensable in cutting-edge fields.

Note: As these developments unfold, you’ll witness a new era of innovation driven by advanced coating technologies.

Silicon carbide coating on graphite components is transforming industries by delivering unmatched durability, thermal stability, and resistance to corrosion. You see its impact in semiconductors, solar energy, aerospace, and other advanced technologies. These applications are driving innovation and shaping the future in 2025.

As researchers address challenges like cost and scalability, this technology will continue to evolve. You can expect it to play a critical role in high-performance applications, pushing the boundaries of what’s possible.

Note: By adopting this innovation, you contribute to a future defined by efficiency, sustainability, and technological progress.

FAQ

1. What makes silicon carbide coating better than other coatings?

Silicon carbide coating offers superior durability, thermal stability, and corrosion resistance. It performs well in extreme environments, making it ideal for advanced industries like aerospace and semiconductors.

Tip: Its unique properties reduce maintenance costs and extend component lifespan, saving you time and money.

2. Can silicon carbide-coated graphite components be used in renewable energy systems?

Yes, these components enhance the efficiency of solar panels and photovoltaic systems. They resist corrosion and manage heat effectively, ensuring consistent performance in harsh environmental conditions.

Note: This technology supports the global shift toward sustainable energy solutions.

3. How does silicon carbide coating improve semiconductor manufacturing?

The coating protects graphite susceptors and wafer carriers from wear and oxidation during high-temperature cycles. It ensures precision and reliability, reducing contamination risks in cleanroom environments.

Callout: Using coated components boosts productivity and minimizes defects in semiconductor production.

4. Is silicon carbide coating environmentally friendly?

Researchers are developing eco-friendly coating methods to reduce energy use and emissions. The extended lifespan of coated components also minimizes waste, aligning with sustainable practices.

Emoji: 🌱 Silicon carbide coating contributes to greener manufacturing processes.

5. What challenges exist in scaling up silicon carbide coating production?

High costs and technical complexities can limit scalability. Manufacturers are addressing these issues with automation and innovative coating techniques to make production more efficient and affordable.

Tip: Investing in research helps overcome these challenges and expands industry adoption.

| Contact Us To Get Better Information |

| By:semicera |

| Address : No. 1958 Jiangnan Road, Ningbo High tech Zone, Zhejiang Province, 315201, China |

| E-mail : sales01@semi-cera.com |

| E-mail : sales05@semi-cera.com |

| Tel : 86-0574-8650 3783 |

| Phone : 86-13373889683 |

| Skype : xianeryeah@outlook.com |

| Whatsapp : 86-13373889683 |

| Xing:https://www.xing.com/discover/your-posts |

| Pinterest:https://www.pinterest.com/Semicera/ |

| Facebook:https://www.facebook.com/profile.php?id=61575124466678 |

| Youtube:https://www.youtube.com/@Semicera |