Silicon carbide coating serves as a protective layer known for its exceptional hardness, thermal stability, and resistance to corrosion. This advanced material enhances the durability of components exposed to extreme conditions. Industries such as aerospace and automotive rely on its ability to withstand high temperatures and abrasive environments. In electronics, SIC coating improves the performance of devices by providing thermal management and protection. Variants like SIC carbide coating and SIC Tac coating offer tailored solutions for specific applications, ensuring optimal performance in demanding scenarios.

Key Takeaways

- Silicon carbide coating is very hard and handles heat well.

- It works great in tough places like airplanes and cars.

- This coating makes parts last longer and need less fixing.

- It helps save money and keeps things working better.

- Silicon carbide coating saves energy in things like solar panels.

- It stops energy loss and spreads heat more evenly.

- The coating is safe for the environment and cuts down waste.

- It helps green tech without using harmful materials.

- Ways like vapor coating and heat spraying apply it carefully.

- These methods make sure it works well for many industries.

Understanding Silicon Carbide

What is Silicon Carbide?

Silicon carbide, often abbreviated as SiC, is a compound composed of silicon and carbon atoms. It occurs naturally as a rare mineral called moissanite but is primarily produced synthetically for industrial use. This material exhibits a crystalline structure, which contributes to its remarkable physical and chemical properties. Silicon carbide has become a cornerstone in modern engineering due to its ability to perform under extreme conditions.

The production of silicon carbide involves heating silica sand and carbon at high temperatures in an electric furnace. This process creates a material that is both lightweight and incredibly strong. Its unique characteristics make it suitable for applications requiring high durability and resistance to wear.

Key Properties of Silicon Carbide

Hardness and Durability

Silicon carbide ranks just below diamond on the Mohs scale of hardness. This exceptional hardness allows it to resist scratches and abrasions, even in the most demanding environments. Its durability ensures a long lifespan for components made from or coated with this material. Industries rely on silicon carbide for applications where mechanical strength is critical.

Thermal and Chemical Stability

Silicon carbide can withstand extreme temperatures without losing its structural integrity. It remains stable at temperatures exceeding 2,000°C, making it ideal for high-temperature applications. Additionally, it resists chemical reactions with acids, bases, and other corrosive substances. This stability ensures reliable performance in harsh chemical environments.

Types of Silicon Carbide

Alpha and Beta Silicon Carbide

Silicon carbide exists in two primary crystalline forms: alpha and beta. Alpha silicon carbide forms at high temperatures and exhibits a hexagonal crystal structure. Beta silicon carbide, on the other hand, forms at lower temperatures and has a cubic structure. Each type offers unique advantages, depending on the application.

Polycrystalline and Monocrystalline Forms

Silicon carbide can also be classified based on its crystal arrangement. Polycrystalline silicon carbide consists of multiple small crystals, providing enhanced toughness. Monocrystalline silicon carbide, with its single-crystal structure, offers superior optical and electronic properties. These variations allow manufacturers to tailor the material for specific industrial needs.

Silicon Carbide Coating: Properties and Production

What is Silicon Carbide Coating?

Silicon carbide coating is a specialized layer applied to surfaces to enhance their performance in extreme conditions. This coating leverages the unique properties of silicon carbide, such as its hardness, thermal stability, and resistance to wear and corrosion. It acts as a protective barrier, extending the lifespan of components exposed to high temperatures, abrasive environments, or harsh chemicals. Industries use silicon carbide coating to improve the reliability and efficiency of critical equipment.

Methods of Producing Silicon Carbide Coatings

Chemical Vapor Deposition (CVD)

Chemical vapor deposition is a common method for producing silicon carbide coatings. This process involves introducing a gas mixture containing silicon and carbon compounds into a heated chamber. The high temperature causes the compounds to react and form a thin, uniform layer of silicon carbide on the substrate. CVD produces coatings with excellent adhesion and precise thickness control, making it ideal for applications requiring high precision.

Physical Vapor Deposition (PVD)

Physical vapor deposition is another technique used to create silicon carbide coatings. In this method, silicon carbide material is vaporized in a vacuum chamber and then deposited onto the target surface. PVD coatings are known for their smooth finish and high durability. This method is often used in industries where components must endure significant mechanical stress.

Thermal Spraying Techniques

Thermal spraying techniques involve melting silicon carbide particles and spraying them onto a surface at high velocity. This method creates a thick, durable coating that can withstand extreme wear and tear. Thermal spraying is particularly useful for large components or surfaces that require enhanced abrasion resistance.

Unique Properties of Silicon Carbide Coatings

High-Temperature Resistance

Silicon carbide coatings exhibit exceptional resistance to high temperatures. They maintain their structural integrity even when exposed to temperatures exceeding 2,000°C. This property makes them indispensable in industries like aerospace and energy, where components must perform reliably under intense heat.

Exceptional Wear and Corrosion Resistance

Silicon carbide coatings provide outstanding protection against wear and corrosion. Their hardness prevents surface damage from abrasion, while their chemical stability resists degradation from acids, bases, and other corrosive substances. These qualities ensure long-lasting performance in demanding environments.

Applications of Silicon Carbide Coating in Modern Industries

Aerospace Industry

Thermal Protection Systems

Silicon carbide coating plays a vital role in thermal protection systems for aerospace applications. Spacecraft and aircraft components often face extreme heat during operation, especially during re-entry into the atmosphere. The coating provides a robust thermal barrier, ensuring that critical parts maintain their structural integrity. Its ability to withstand temperatures exceeding 2,000°C makes it indispensable for protecting heat shields and other high-temperature components.

Abrasion-Resistant Components

Aerospace components frequently encounter abrasive forces due to high-speed airflow and particulate matter. Silicon carbide coating enhances the durability of these parts by resisting wear and tear. Turbine blades, engine nozzles, and other exposed surfaces benefit from this coating, which extends their operational lifespan and reduces maintenance costs.

Automotive Industry

Engine Components

In the automotive sector, silicon carbide coating improves the performance and longevity of engine components. Pistons, cylinders, and valves coated with this material exhibit reduced friction and wear. This enhancement leads to better fuel efficiency and lower emissions. The coating also protects engine parts from thermal degradation, ensuring reliable operation under high-temperature conditions.

Brake Systems

Brake systems in modern vehicles demand materials that can endure high friction and heat. Silicon carbide coating provides the necessary hardness and thermal stability for brake rotors and pads. This coating ensures consistent braking performance, even under intense conditions, while minimizing wear. Its application contributes to safer and more efficient braking systems.

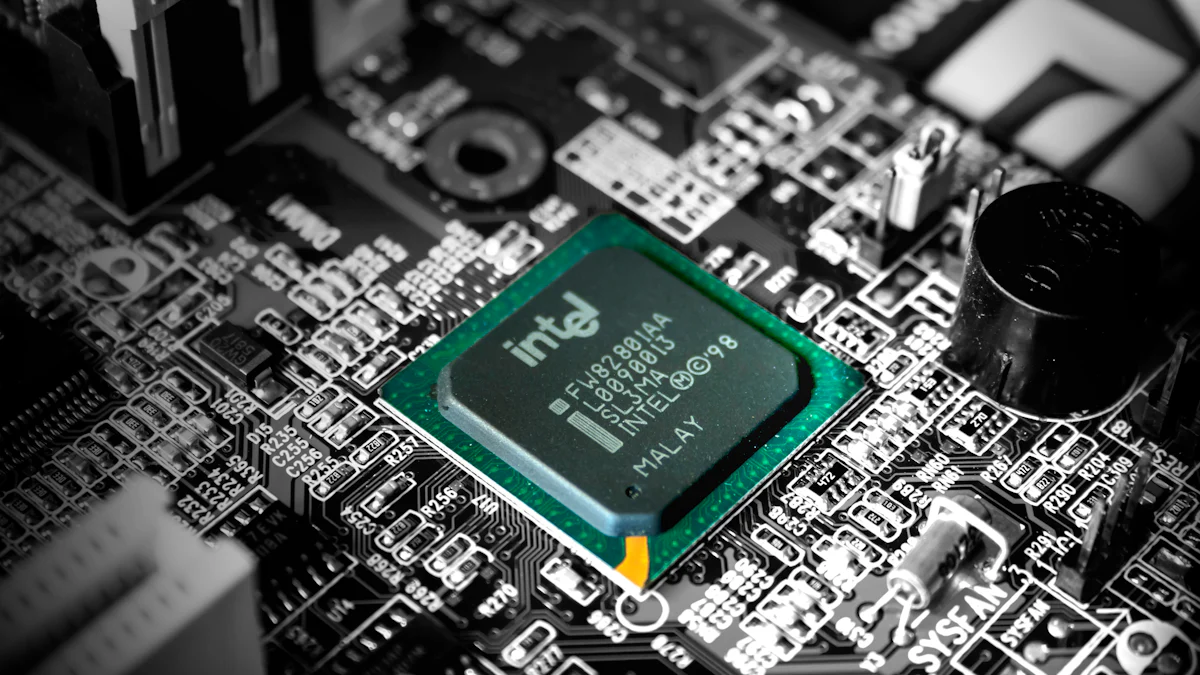

Electronics and Semiconductor Industry

Heat Dissipation in High-Power Devices

High-power electronic devices generate significant heat during operation. Silicon carbide coating aids in heat dissipation, preventing overheating and ensuring stable performance. Power modules, transistors, and other components benefit from this property, which enhances their reliability and efficiency.

Protective Layers for Microelectronics

Microelectronics require protection from environmental factors such as moisture, chemicals, and mechanical stress. Silicon carbide coating serves as a protective layer, shielding delicate circuits and components. Its chemical stability and durability make it an ideal choice for safeguarding microchips and other sensitive electronic parts.

Energy Sector

Solar Panels and Photovoltaics

Silicon carbide coating enhances the efficiency and durability of solar panels. Photovoltaic cells often operate in harsh outdoor environments, where they face exposure to ultraviolet radiation, moisture, and temperature fluctuations. The coating protects the cells by forming a robust barrier against these elements. Its exceptional thermal stability ensures that the panels maintain optimal performance even in extreme heat. This property is particularly valuable in regions with high solar intensity.

The coating also improves the energy conversion efficiency of solar panels. It minimizes energy loss by reducing surface reflection, allowing more sunlight to penetrate the cells. Manufacturers use this technology to produce panels that deliver higher energy output over their lifespan. Additionally, the wear resistance of silicon carbide coating reduces maintenance requirements, making solar energy systems more cost-effective in the long term.

Nuclear Reactor Components

Nuclear reactors demand materials that can endure extreme conditions, including high radiation levels and intense heat. Silicon carbide coating plays a critical role in protecting reactor components. It provides a strong shield against radiation damage, ensuring the structural integrity of fuel cladding and other critical parts. This protection reduces the risk of material degradation, which can compromise reactor safety.

The coating's chemical stability prevents reactions with coolant fluids and other substances inside the reactor. This resistance to corrosion extends the lifespan of components and enhances operational reliability. Engineers also value its ability to withstand temperatures exceeding 2,000°C, which is essential for advanced reactor designs. By incorporating silicon carbide coating, the nuclear industry achieves safer and more efficient energy production.

Advantages of Silicon Carbide Coating Over Other Materials

Comparison with Traditional Coatings

Superior Hardness and Wear Resistance

Silicon carbide coating offers unmatched hardness compared to traditional coatings like chromium or nickel-based layers. Its position near diamond on the Mohs scale ensures exceptional resistance to scratches and abrasions. This property makes it ideal for applications where surfaces face constant mechanical stress. For example, components in aerospace and automotive industries benefit from its ability to maintain structural integrity under heavy wear. Traditional coatings often fail in such demanding environments, leading to frequent replacements or repairs.

Better Performance in Extreme Environments

Extreme environments demand materials that can endure high temperatures, corrosive chemicals, or intense radiation. Silicon carbide coating excels in these conditions. It remains stable at temperatures exceeding 2,000°C, unlike many conventional coatings that degrade or lose effectiveness. Its chemical resistance also prevents reactions with acids, bases, and other corrosive agents. This reliability ensures consistent performance in industries like energy and electronics, where traditional coatings may falter.

Cost-Effectiveness in the Long Term

Although the initial cost of applying silicon carbide coating may be higher than traditional options, its long-term benefits outweigh the expense. Its durability reduces the need for frequent maintenance or replacement of components. Industries save money by avoiding downtime and extending the lifespan of critical equipment. Over time, this coating proves to be a cost-effective solution for high-performance applications.

Environmental Benefits

Silicon carbide coating contributes to sustainability by reducing waste and energy consumption. Its long lifespan minimizes the disposal of worn-out components, lowering environmental impact. Additionally, its ability to enhance energy efficiency in applications like solar panels and electronics supports the transition to greener technologies. Unlike some traditional coatings, it does not rely on toxic materials, making it a safer choice for the environment.

Silicon carbide coating offers unmatched properties like hardness, thermal stability, and corrosion resistance. These qualities make it indispensable in industries such as aerospace, automotive, and energy. Its ability to enhance durability and efficiency has revolutionized modern engineering.

Researchers continue to explore innovative methods to improve silicon carbide coating technologies. Future advancements may lead to even greater performance, cost-efficiency, and environmental benefits. This progress will further solidify its role as a critical material in advancing industrial applications.

FAQ

What industries benefit the most from silicon carbide coating?

Aerospace, automotive, electronics, and energy sectors benefit significantly. These industries rely on silicon carbide coating for its durability, thermal stability, and corrosion resistance, which enhance the performance and lifespan of critical components.

How does silicon carbide coating improve energy efficiency?

Silicon carbide coating reduces energy loss by minimizing surface reflection and improving heat dissipation. This property enhances the efficiency of solar panels, high-power electronics, and other energy-related applications.

Is silicon carbide coating environmentally friendly?

Yes, silicon carbide coating is environmentally friendly. Its durability reduces waste by extending the lifespan of components. It also supports green technologies like solar energy and avoids the use of toxic materials found in some traditional coatings.

Can silicon carbide coating withstand extreme temperatures?

Silicon carbide coating can endure temperatures exceeding 2,000°C. This makes it ideal for applications in aerospace, energy, and automotive industries where components face intense heat.

What are the main methods used to apply silicon carbide coating?

The primary methods include chemical vapor deposition (CVD), physical vapor deposition (PVD), and thermal spraying. Each method offers unique advantages, such as precision, durability, or suitability for large surfaces.