Silicon carbide coating stands out for its exceptional durability, thermal stability, and resistance to corrosion. You can find it playing a vital role in industries that demand high performance, such as aerospace, electronics, and energy. Its ability to withstand extreme conditions makes it indispensable in these fields. The applications of SiC coating continue to expand as industries face modern challenges like higher efficiency and sustainability. Whether it’s the aerospace sector or SIC Tac coating in electronics, this technology offers solutions that push the boundaries of innovation.

Key Takeaways

- SiC coating is strong, heat-resistant, and prevents rust, perfect for tough industries.

- It helps parts last longer by shielding them from damage, heat, and chemicals, saving money on repairs.

- SiC coating can be used in planes, gadgets, energy, and new areas like medical tools and water cleaning.

- New ideas in SiC coating make it cheaper and better for the planet, helping create greener solutions.

- Knowing how SiC coating works helps industries work better and stay reliable in tough conditions.

Understanding SiC Coating

What is SiC Coating?

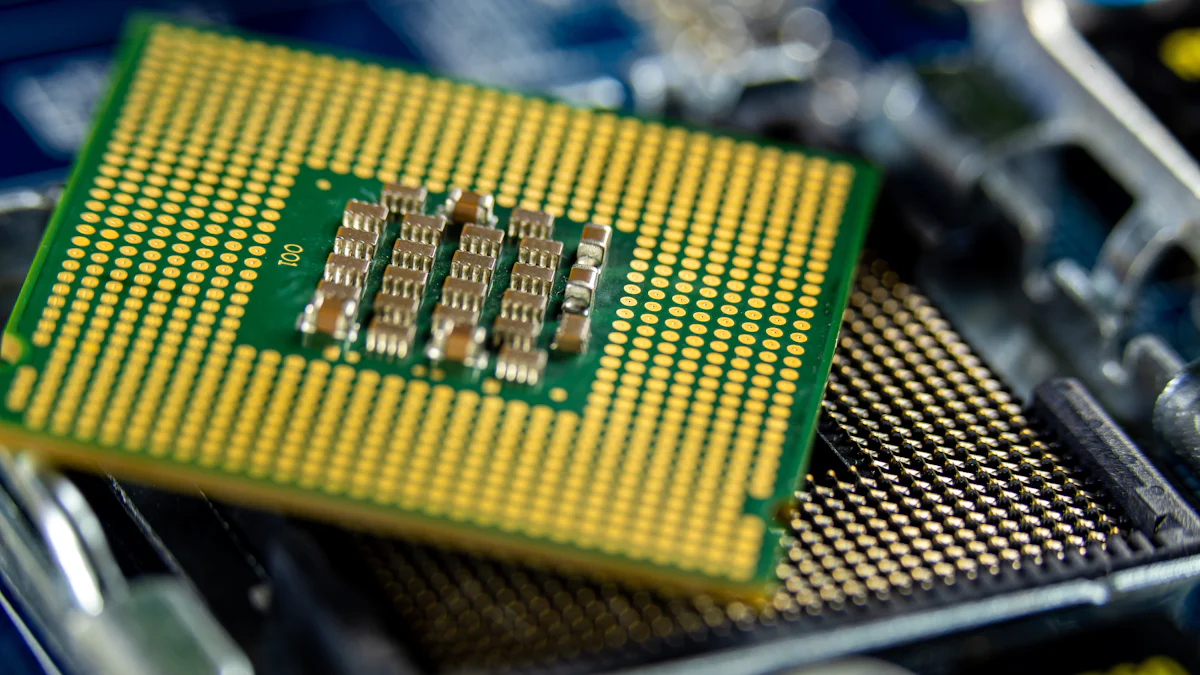

Silicon carbide (SiC) coating is a thin, protective layer made from silicon carbide material. You’ll find it used to enhance the surface properties of various components. This coating provides exceptional hardness, thermal stability, and resistance to wear and corrosion. Manufacturers apply it to materials like metals, ceramics, and composites to improve their performance in demanding environments.

SiC coating acts as a shield, protecting surfaces from extreme temperatures, chemical exposure, and mechanical stress. Its unique properties make it a preferred choice in industries where durability and reliability are critical.

Did You Know? SiC is one of the hardest materials known, ranking just below diamond on the Mohs scale of hardness.

Key Properties of SiC Coating

SiC coating offers several remarkable properties that set it apart:

- High Hardness: It resists scratches and abrasions, ensuring long-lasting performance.

- Thermal Stability: It can withstand temperatures exceeding 1,000°C without degrading.

- Corrosion Resistance: It protects against chemical attacks, even in harsh environments.

- Low Friction: Its smooth surface reduces wear and tear on moving parts.

- Electrical Conductivity: It can conduct electricity, making it useful in electronic applications.

These properties make SiC coating an ideal solution for industries that demand high performance and reliability.

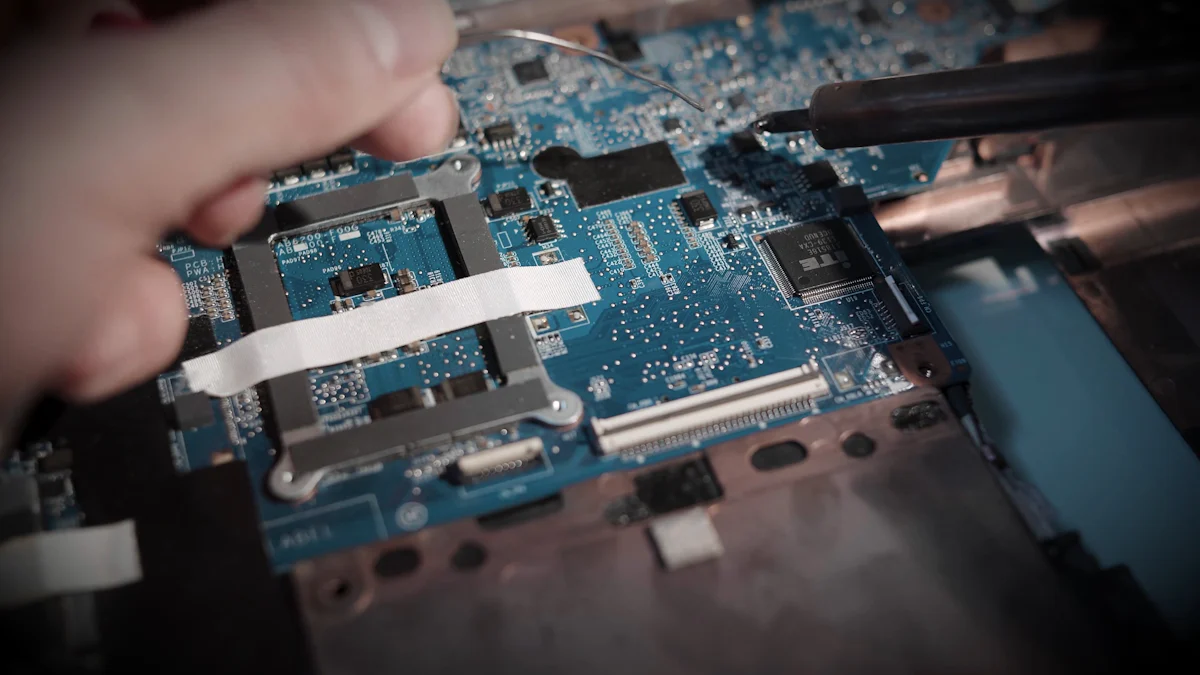

How SiC Coating is Manufactured

The manufacturing process for SiC coating involves advanced techniques to ensure precision and quality. Here’s a simplified overview:

- Surface Preparation: The base material is cleaned and treated to ensure proper adhesion.

- Coating Application: SiC is applied using methods like chemical vapor deposition (CVD) or plasma spraying.

- Curing and Finishing: The coated material is heated to bond the SiC layer, followed by polishing for a smooth finish.

Each step ensures the coating adheres properly and delivers the desired performance. You’ll notice that these processes are designed to meet the specific needs of different industries.

Tip: The choice of manufacturing method depends on the application and the material being coated.

Benefits of SiC Coating

Durability and Wear Resistance

SiC coating offers unmatched durability. Its high hardness protects surfaces from scratches, abrasions, and mechanical wear. You can rely on this coating to extend the lifespan of components exposed to constant friction or heavy loads. For example, in industrial machinery, SiC-coated parts maintain their integrity even after prolonged use.

Tip: If you want to reduce maintenance costs, SiC coating is an excellent choice. Its wear resistance minimizes the need for frequent repairs or replacements.

The coating also performs well in abrasive environments. Whether it’s sand, dust, or other particles, SiC acts as a shield, preventing damage to the underlying material. This makes it ideal for applications in mining, manufacturing, and other demanding industries.

Thermal Stability and High-Temperature Performance

SiC coating excels in high-temperature environments. It remains stable at temperatures exceeding 1,000°C, making it suitable for extreme conditions. You’ll find it used in furnaces, turbines, and other heat-intensive applications.

The coating’s thermal stability ensures consistent performance. It doesn’t degrade or lose its protective properties when exposed to heat. This reliability is crucial in industries like aerospace and energy, where components must endure extreme temperatures without failure.

Did You Know? SiC coating not only withstands heat but also helps dissipate it. This property improves the efficiency of heat exchangers and other thermal systems.

Corrosion and Chemical Resistance

SiC coating provides excellent protection against corrosion. It resists chemical attacks from acids, alkalis, and other harsh substances. If you work in chemical processing or marine environments, this coating can safeguard your equipment from damage.

The coating forms a barrier that prevents corrosive agents from reaching the base material. This extends the life of components and reduces the risk of failure. For example, in pipelines and storage tanks, SiC coating ensures long-term reliability.

Note: SiC coating is also resistant to oxidation, making it a great choice for applications exposed to both heat and corrosive gases.

By choosing SiC coating, you can enhance the performance and longevity of your equipment in challenging environments.

Longevity in Extreme Environments

SiC coating ensures that components last longer, even in the harshest conditions. You’ll find it particularly valuable in environments where extreme temperatures, mechanical stress, or chemical exposure are constant challenges. Its unique properties allow it to protect materials from degradation, ensuring reliable performance over time.

In high-temperature settings, SiC coating maintains its integrity. It doesn’t crack, warp, or lose its protective qualities, even when exposed to temperatures exceeding 1,000°C. This makes it ideal for applications like gas turbines, industrial furnaces, and heat exchangers. By using SiC-coated components, you can reduce the risk of failure and extend the operational life of your equipment.

Tip: If you work in industries like aerospace or energy, SiC coating can help you achieve greater efficiency by reducing downtime caused by wear and tear.

SiC coating also excels in resisting wear in abrasive environments. Whether it’s sand, dust, or other particles, the coating acts as a shield, preventing surface damage. This durability is crucial in industries like mining and manufacturing, where equipment often faces constant friction and impact.

Additionally, SiC coating provides unmatched protection against corrosion. It forms a barrier that resists chemical attacks, even in environments with strong acids or alkalis. For example, in marine or chemical processing industries, SiC-coated components can withstand years of exposure without significant wear.

Did You Know? SiC coating’s resistance to oxidation further enhances its longevity, making it a top choice for applications exposed to both heat and corrosive gases.

By choosing SiC coating, you can ensure that your equipment performs reliably, even in the most extreme conditions. This not only reduces maintenance costs but also boosts overall productivity.

Applications of SiC Coating Across Industries

Aerospace and Defense

You’ll find SiC coating playing a critical role in aerospace and defense. Components in these industries face extreme conditions, including high temperatures, intense friction, and exposure to corrosive environments. SiC coating protects turbine blades, engine parts, and heat shields, ensuring they perform reliably under stress. Its thermal stability allows aircraft and spacecraft to operate efficiently, even in the most demanding situations.

In defense, SiC coating enhances the durability of missile components and radar systems. It resists wear and corrosion, extending the lifespan of critical equipment. By using SiC-coated parts, you can reduce maintenance needs and improve operational readiness. This makes it an essential material for advancing aerospace and defense technologies.

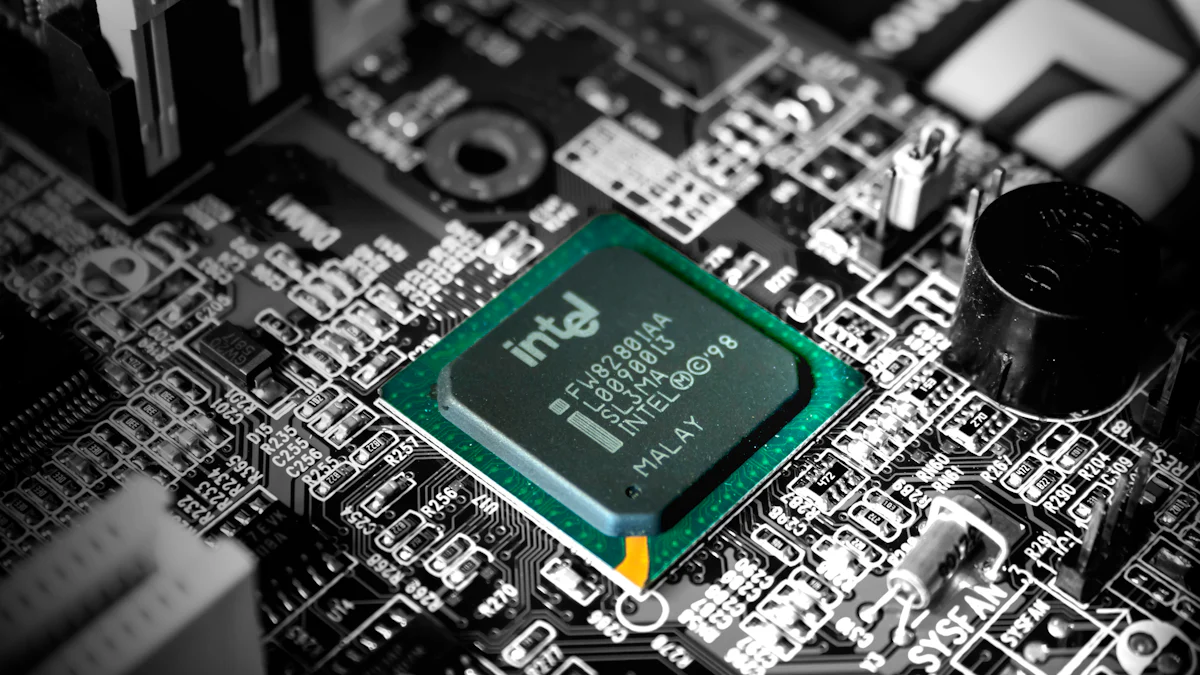

Electronics and Semiconductors

The electronics industry relies on SiC coating for its unique combination of hardness, thermal stability, and electrical conductivity. You’ll see it used in semiconductor manufacturing, where precision and reliability are vital. SiC-coated wafers and tools resist wear during production, ensuring consistent performance.

In power electronics, SiC coating improves the efficiency of devices like inverters and transistors. It dissipates heat effectively, preventing overheating and enhancing energy efficiency. This makes it a key material for modern electronics, especially in applications like electric vehicles and renewable energy systems.

Tip: SiC coating’s low friction properties also reduce wear on moving parts in electronic devices, increasing their lifespan.

Energy and Power Generation

SiC coating has transformed energy and power generation. In gas turbines and nuclear reactors, it protects components from extreme heat and corrosive gases. This ensures reliable operation and reduces the risk of failure.

You’ll also find SiC coating in solar panels and wind turbines. It shields surfaces from environmental damage, such as UV radiation and abrasive particles. This improves the efficiency and durability of renewable energy systems. By using SiC-coated components, you can enhance the performance of power generation equipment while lowering maintenance costs.

Did You Know? SiC coating’s ability to withstand high temperatures makes it ideal for heat exchangers, where efficient thermal transfer is crucial.

Automotive and Transportation

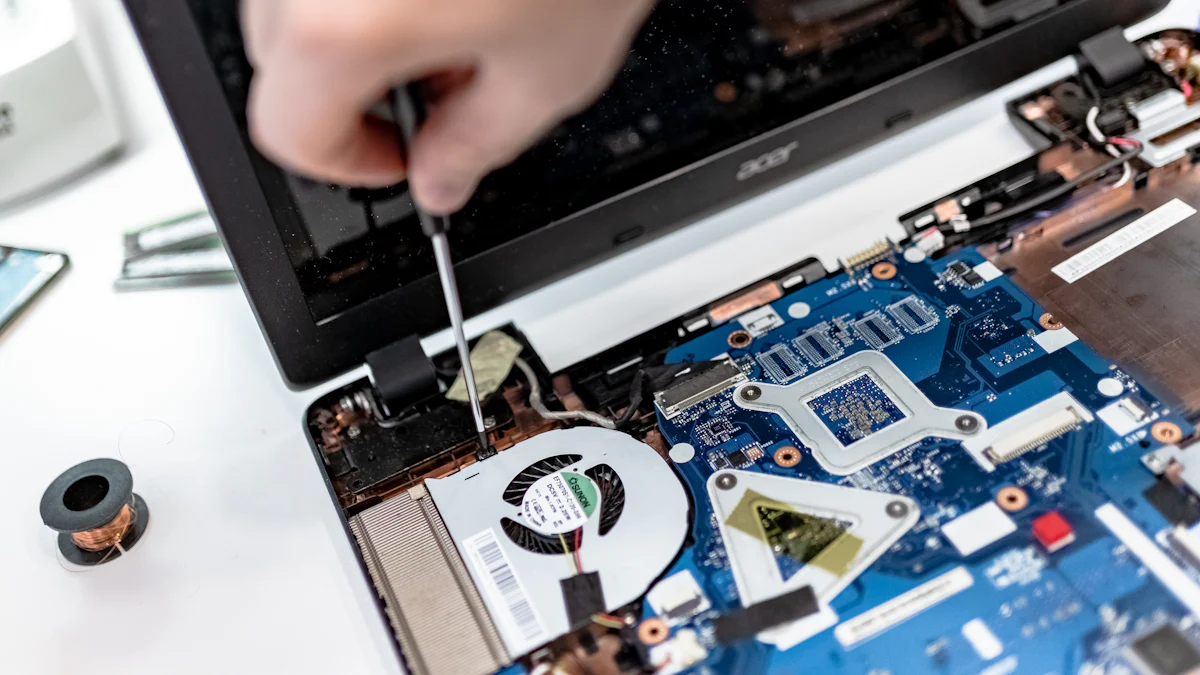

SiC coating has revolutionized the automotive and transportation industries. You’ll find it enhancing the performance and durability of critical components in vehicles. Its ability to withstand high temperatures and resist wear makes it ideal for engines, exhaust systems, and braking components. By using SiC-coated parts, manufacturers improve vehicle efficiency and reduce maintenance needs.

In electric vehicles (EVs), SiC coating plays a vital role in power electronics. It helps dissipate heat from inverters and chargers, ensuring optimal performance. This improves energy efficiency and extends the lifespan of EV components. You’ll also notice SiC coating in fuel cells and battery systems, where it protects against chemical degradation.

Tip: SiC coating can help you achieve better fuel efficiency by reducing friction and wear in moving parts.

The coating also benefits the transportation sector. In trains and aircraft, SiC-coated components handle extreme conditions like high speeds and intense friction. This ensures reliable operation and reduces downtime. Whether it’s a high-speed train or a commercial jet, SiC coating enhances safety and performance.

Emerging Applications in Medical and Water Filtration

The applications of SiC coating are expanding into medical and water filtration fields. In medical devices, SiC coating provides a biocompatible and durable surface. You’ll see it used in surgical tools, implants, and diagnostic equipment. Its resistance to wear and corrosion ensures these devices perform reliably over time.

In water filtration, SiC coating offers unique advantages. It creates a robust and chemically resistant surface for filtration membranes. This allows them to handle harsh conditions, such as high temperatures and aggressive chemicals. SiC-coated membranes improve filtration efficiency and extend the lifespan of water treatment systems.

Did You Know? SiC-coated membranes are increasingly used in desalination plants to produce clean drinking water from seawater.

These emerging applications of SiC coating highlight its versatility. Whether you’re in the medical field or working on water treatment solutions, this technology provides innovative ways to address modern challenges.

Future Potential of SiC Coating

Innovations in SiC Coating Technology

SiC coating technology continues to evolve with groundbreaking innovations. Researchers are exploring advanced deposition methods like atomic layer deposition (ALD) to achieve ultra-thin, uniform coatings. These methods enhance precision and improve performance in applications requiring extreme accuracy, such as semiconductors and medical devices.

You’ll also notice a shift toward eco-friendly manufacturing processes. Scientists are developing techniques that reduce energy consumption and minimize waste during production. For instance, plasma-enhanced chemical vapor deposition (PECVD) offers a more sustainable alternative while maintaining high-quality results.

Did You Know? Nanostructured SiC coatings are emerging as a game-changer. These coatings provide enhanced surface properties, including improved hardness and thermal conductivity.

Innovations like these pave the way for SiC coating to meet the demands of next-generation technologies.

Addressing Challenges and Limitations

Despite its advantages, SiC coating faces challenges. High production costs remain a significant barrier. The complex manufacturing processes and specialized equipment required for SiC coating contribute to its expense. You might find this limits its adoption in cost-sensitive industries.

Another challenge involves adhesion to certain materials. Ensuring a strong bond between the SiC layer and the substrate can be difficult, especially for non-metallic surfaces. Researchers are working on improving surface preparation techniques to address this issue.

Tip: Collaboration between industries and research institutions can accelerate solutions to these challenges. By sharing knowledge, you can help drive innovation and reduce costs.

Overcoming these limitations will make SiC coating more accessible and versatile.

Market Trends and Growth Opportunities

The market for SiC coating is expanding rapidly. Industries like aerospace, electronics, and renewable energy are driving demand. You’ll see a growing need for SiC-coated components in electric vehicles (EVs) and 5G technology, where durability and thermal management are critical.

Emerging markets, such as medical devices and water filtration, also present significant growth opportunities. The biocompatibility and chemical resistance of SiC coatings make them ideal for these applications. Additionally, the push for sustainability is encouraging industries to adopt SiC coatings for their long-lasting performance and reduced environmental impact.

Did You Know? Analysts predict the global SiC coating market will grow at a compound annual growth rate (CAGR) of over 7% in the next decade.

By staying informed about these trends, you can position yourself to take advantage of the expanding opportunities in this field.

SiC coating offers unmatched benefits, including exceptional durability, thermal stability, and resistance to corrosion. These properties make it a reliable solution for industries like aerospace, electronics, and energy. You can see its impact in solving challenges like wear, heat, and chemical exposure.

Key Takeaway: SiC coating not only enhances performance but also extends the lifespan of critical components.

Emerging markets, such as medical devices and water filtration, highlight its growing importance. With ongoing innovations, you can expect SiC coating to play a pivotal role in shaping sustainable and high-performance technologies.

FAQ

What makes SiC coating different from other coatings?

SiC coating stands out due to its exceptional hardness, thermal stability, and resistance to corrosion. Unlike many coatings, it performs well in extreme environments, including high temperatures and abrasive conditions. Its unique properties make it ideal for industries requiring durability and reliability.

Tip: SiC coating is second only to diamond in hardness, ensuring unmatched wear resistance.

Can SiC coating be applied to all materials?

SiC coating works best on metals, ceramics, and composites. However, it may not adhere well to certain non-metallic surfaces. Manufacturers use advanced surface preparation techniques to improve adhesion and ensure optimal performance.

Note: Consult with experts to determine if SiC coating suits your specific material and application.

Is SiC coating environmentally friendly?

Yes, SiC coating is eco-friendly. Its durability reduces the need for frequent replacements, minimizing waste. New manufacturing methods, like plasma-enhanced chemical vapor deposition (PECVD), also lower energy consumption and environmental impact.

Did You Know? SiC-coated components last longer, reducing the carbon footprint of industrial operations.

How does SiC coating improve energy efficiency?

SiC coating enhances energy efficiency by dissipating heat effectively. It prevents overheating in devices like inverters and turbines. This property is especially valuable in power electronics and renewable energy systems.

Emoji Insight: ⚡ SiC coating helps electric vehicles and solar panels operate more efficiently, saving energy and costs.

What industries benefit the most from SiC coating?

Industries like aerospace, electronics, energy, and automotive benefit significantly. SiC coating protects components from wear, heat, and corrosion. Emerging fields like medical devices and water filtration are also adopting this technology for its unique advantages.

Key Takeaway: SiC coating’s versatility makes it a valuable solution across diverse industries.