Used silicon carbide dummy wafers are essential in the semiconductor industry, serving as non-functional placeholders during manufacturing and testing processes. These black silicon carbide dummy wafers are known for their durability, allowing them to withstand high temperatures and voltages, making them suitable for various applications. Manufacturers often rely on silicon carbide dummy wafers to ensure equipment reliability and process optimization. If you're looking for a silicon carbide dummy wafer nearby, the market is expanding rapidly, with projections indicating growth from USD 0.35 billion in 2022 to USD 1.10 billion by 2030. This growth highlights the increasing importance of silicon carbide dummy wafers for sale in semiconductor production.

Key Takeaways

- Silicon carbide dummy wafers are essential for optimizing semiconductor manufacturing processes, serving as non-functional placeholders that enhance efficiency and reduce resource waste.

- These wafers are known for their durability, able to withstand high temperatures and voltages, making them ideal for rigorous testing and calibration of semiconductor equipment.

- Using silicon carbide dummy wafers can significantly lower production costs by allowing extensive testing without the need for expensive functional wafers.

- Their robust nature helps ensure equipment reliability, reducing downtime and maintenance costs by identifying potential issues before they impact actual production.

- Silicon carbide dummy wafers are increasingly being adopted in emerging technologies, particularly in the automotive and power electronics sectors, due to their superior thermal conductivity.

- Future advancements in material science promise to enhance the properties of silicon carbide dummy wafers, further driving innovation in semiconductor manufacturing.

- Proper handling and storage of silicon carbide dummy wafers are crucial to maintaining their integrity and performance, emphasizing the need for strict protocols in manufacturing environments.

What Are Silicon Carbide Dummy Wafers?

Silicon carbide dummy wafers play a crucial role in the semiconductor industry. These wafers serve as non-functional placeholders, primarily used for testing, calibration, and transportation. They mimic the characteristics of real silicon wafers, allowing manufacturers to optimize production processes without using actual functioning wafers. This approach not only conserves resources but also enhances the efficiency of semiconductor manufacturing.

Composition and Characteristics

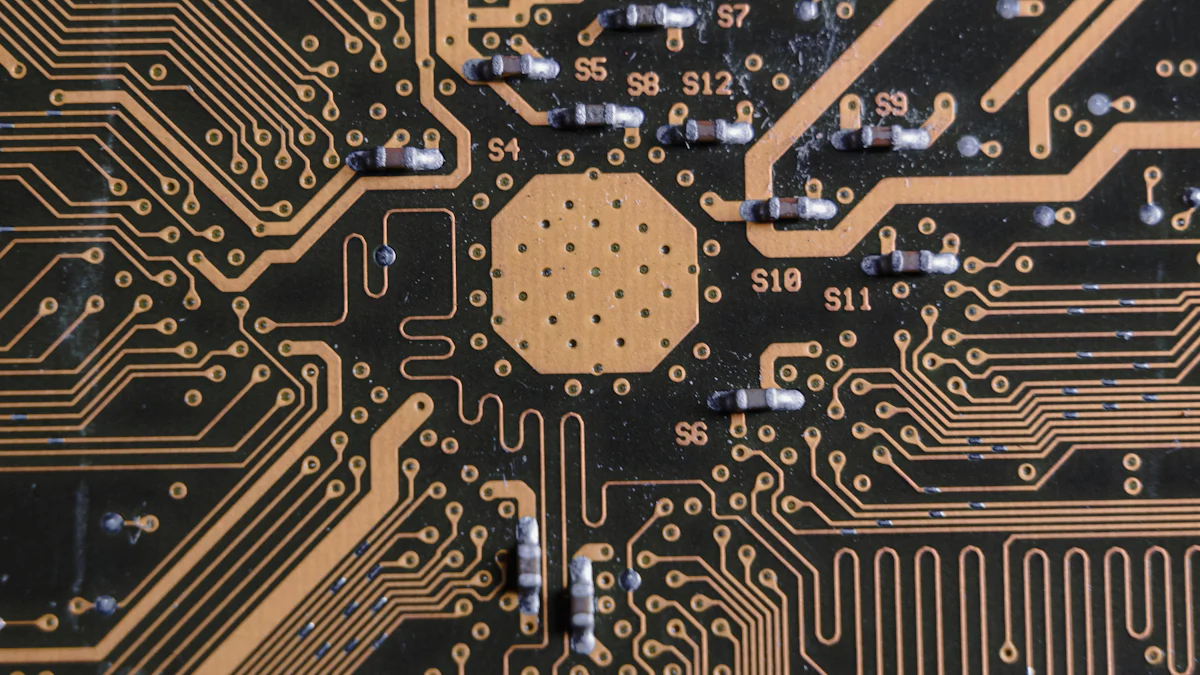

Silicon carbide dummy wafers are composed of silicon carbide material, renowned for its superior thermal and electrical conductivity properties. The manufacturing process involves coating silicon carbide on a graphite substrate using a Chemical Vapor Deposition (CVD) method. This technique ensures improved adhesion and reduces particle generation compared to conventional silicon dummy wafers. The robust nature of silicon carbide allows these wafers to withstand high temperatures and voltages, making them ideal for various applications in the semiconductor industry.

Comparison with Other Dummy Wafers

When comparing silicon carbide dummy wafers to other types of dummy wafers, several advantages become apparent. Traditional silicon dummy wafers may not offer the same level of durability and thermal resistance as their silicon carbide counterparts. The used silicon carbide dummy wafer provides enhanced performance due to its unique composition, which includes a CVD-coated graphite substrate. This results in better adhesion and reduced contamination risks, making them a preferred choice for semiconductor manufacturers seeking reliability and efficiency in their processes.

Applications in Equipment Testing

Silicon carbide dummy wafers play a pivotal role in the testing and calibration of semiconductor equipment. Their unique properties make them indispensable in ensuring the accuracy and reliability of various tools used in semiconductor manufacturing.

Calibration of Semiconductor Tools

Manufacturers utilize silicon carbide dummy wafers to calibrate semiconductor tools effectively. These wafers, known for their durability and thermal resistance, provide a stable platform for testing. By simulating real production conditions, they help in fine-tuning equipment settings, ensuring that tools operate at optimal levels. The use of silicon carbide dummy wafers in calibration processes enhances the precision of measurements and adjustments, leading to improved product quality and consistency.

Ensuring Equipment Reliability

The reliability of semiconductor equipment is crucial for maintaining high production standards. Silicon carbide dummy wafers contribute significantly to this aspect by serving as test subjects during equipment evaluations. Their ability to withstand extreme conditions allows manufacturers to assess the performance and durability of their tools under various scenarios. This testing process helps identify potential issues before they affect actual production, reducing downtime and maintenance costs. The use of silicon carbide dummy wafers ensures that equipment remains reliable and efficient, supporting the overall productivity of semiconductor manufacturing facilities.

Role in Process Development

Silicon carbide dummy wafers play a pivotal role in the development of semiconductor manufacturing processes. Their unique properties make them indispensable for testing and optimizing new manufacturing techniques.

Testing New Manufacturing Processes

Manufacturers rely on silicon carbide dummy wafers to test new manufacturing processes. These wafers simulate real production conditions, allowing engineers to evaluate the effectiveness of new techniques without risking valuable functional wafers. The high temperature resistance and durability of silicon carbide make these wafers ideal for rigorous testing environments. By using silicon carbide dummy wafers, manufacturers can identify potential issues early in the development phase, ensuring that new processes meet the required standards before full-scale production begins.

Optimizing Process Parameters

Silicon carbide dummy wafers also aid in optimizing process parameters. Engineers use these wafers to fine-tune variables such as temperature, pressure, and chemical concentrations. The precise surface roughness of silicon carbide dummy wafers, ranging from 0.01 to 0.7 μm, enhances film adhesion and reduces particle generation. This improvement leads to more efficient manufacturing processes and higher operating rates. By optimizing these parameters, manufacturers can achieve greater efficiency and reduced energy loss, ultimately enhancing the overall performance of semiconductor devices.

Tool Qualification and Maintenance

Silicon carbide dummy wafers play a crucial role in the qualification and maintenance of semiconductor tools. Their unique properties make them indispensable for ensuring that equipment operates at peak performance and remains free from contamination.

Verifying Tool Performance

Manufacturers use silicon carbide dummy wafers to verify the performance of semiconductor tools. These wafers provide a stable and consistent platform for testing, allowing engineers to assess tool accuracy and efficiency. By simulating real production conditions, silicon carbide dummy wafers help identify any discrepancies in tool performance. This proactive approach ensures that equipment functions correctly, reducing the likelihood of defects in the final products. The use of these wafers in performance verification enhances the overall reliability of semiconductor manufacturing processes.

Reducing Contamination Risks

Contamination poses a significant risk in semiconductor manufacturing. Silicon carbide dummy wafers help mitigate this risk by serving as test subjects during equipment maintenance. Their robust nature allows them to withstand rigorous cleaning and testing procedures, ensuring that tools remain free from contaminants. By using silicon carbide dummy wafers, manufacturers can detect and address potential contamination issues before they impact actual production. This preventive measure not only protects the integrity of the manufacturing process but also extends the lifespan of the equipment. The use of silicon carbide dummy wafers in reducing contamination risks underscores their importance in maintaining high production standards.

Benefits of Using Silicon Carbide Dummy Wafers

Cost-Effectiveness

Silicon carbide dummy wafers offer significant cost advantages in semiconductor manufacturing. They allow manufacturers to conduct extensive testing and calibration without using expensive functional wafers. This approach conserves valuable resources and reduces overall production costs. By employing these wafers, companies can optimize their processes and improve efficiency, leading to substantial savings. The use of silicon carbide dummy wafers minimizes waste and maximizes the return on investment, making them a financially prudent choice for the industry.

Durability and Longevity

The durability of silicon carbide dummy wafers stands out as a key benefit. These wafers withstand high temperatures and harsh conditions, ensuring long-lasting performance. Their robust nature reduces the frequency of replacements, which further contributes to cost savings. Manufacturers rely on the longevity of these wafers to maintain consistent testing and calibration processes. The used silicon carbide dummy wafer retains its structural integrity over time, providing reliable results and enhancing the overall productivity of semiconductor operations. This durability ensures that manufacturers can depend on these wafers for extended periods, reducing downtime and maintenance efforts.

Challenges and Considerations

Handling and Storage

Silicon carbide dummy wafers require careful handling and storage to maintain their integrity and performance. Industry professionals emphasize the importance of proper procedures to prevent damage. Mishandling can lead to surface scratches or contamination, which may affect their effectiveness in testing and calibration processes.

To ensure optimal handling, manufacturers should implement strict protocols. These include using cleanroom environments and specialized tools designed for wafer manipulation. Proper training for personnel handling these wafers is also crucial. Storage conditions must be controlled, with temperature and humidity levels monitored to prevent any adverse effects on the wafers' properties.

Compatibility with Different Processes

Compatibility with various semiconductor processes presents another challenge for silicon carbide dummy wafers. As the demand for silicon carbide-based devices grows in industries like automotive, aerospace, and power electronics, ensuring that these wafers can seamlessly integrate into diverse manufacturing environments becomes essential.

Manufacturers must consider the specific requirements of each process when selecting silicon carbide dummy wafers. This involves evaluating factors such as wafer size, thickness, and surface characteristics to match the specifications of the functional wafers they simulate. Additionally, ongoing collaboration with equipment suppliers and process engineers can help address compatibility issues, ensuring that the wafers perform effectively across different applications.

Future Developments in Silicon Carbide Dummy Wafers

Innovations in Material Science

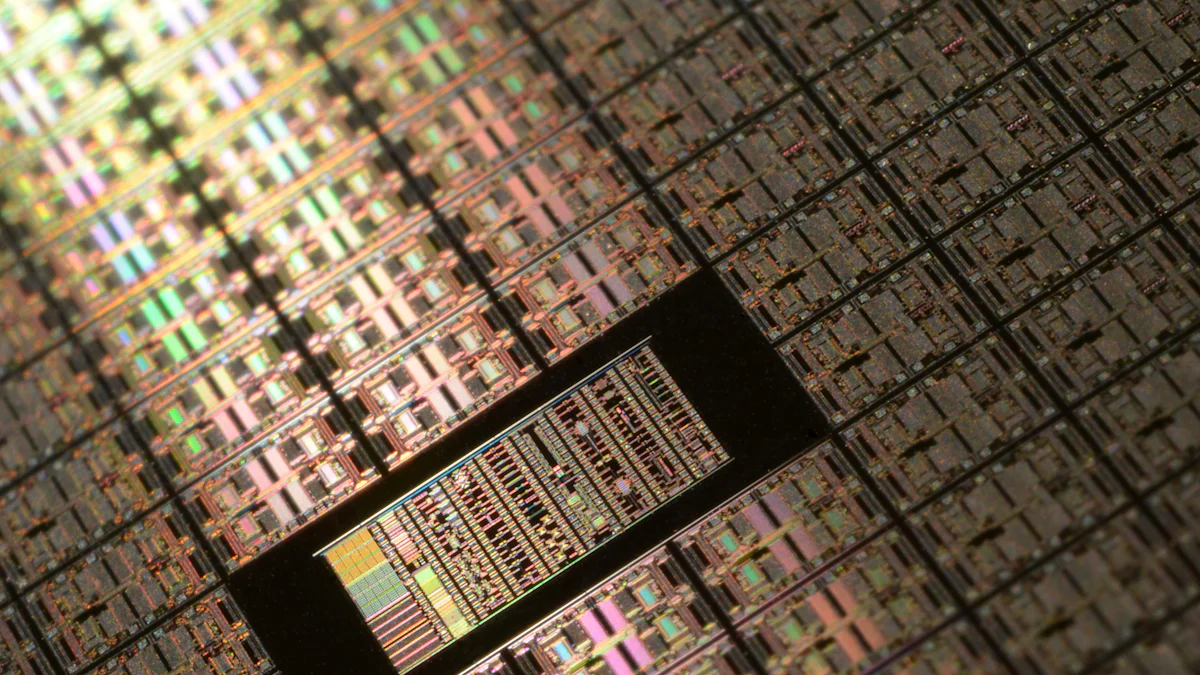

The silicon carbide dummy wafer market is poised for significant advancements, driven by innovations in material science. Researchers and manufacturers are focusing on enhancing the properties of these wafers to meet the growing demands of various industries. One notable development involves improving the surface roughness of silicon carbide wafers. By refining the Chemical Vapor Deposition (CVD) process, manufacturers can achieve a smoother surface, which enhances film adhesion and reduces particle generation. This improvement not only increases the efficiency of semiconductor manufacturing but also extends the lifespan of the wafers.

Moreover, the industry is witnessing efforts to reduce the cost per wafer while maintaining high quality. Companies are investing in advanced manufacturing techniques that increase wafer yield and minimize defects. These innovations are crucial as they enable manufacturers to meet the rising demand for silicon carbide wafers in sectors such as automotive and renewable energy. As a result, the market is expected to experience robust growth, with projections indicating a positive outlook for the coming years.

Expanding Applications in Emerging Technologies

Silicon carbide dummy wafers are finding expanding applications in emerging technologies, particularly in the fields of e-mobility and new energy. The automotive industry, for instance, is increasingly adopting silicon carbide due to its ability to withstand high temperatures and its superior thermal conductivity. These properties make silicon carbide wafers ideal for use in electric vehicles, where efficient heat management is critical.

In addition to automotive applications, silicon carbide wafers are gaining traction in the power semiconductor industry. Their use in power electronics offers improved efficiency and reduced energy loss, which are essential for developing compact and lightweight electronic devices. This trend aligns with the growing preference for miniaturized technology in various sectors, including aerospace and industrial applications.

Manufacturers are also exploring the potential of silicon carbide wafers in other cutting-edge technologies. As the demand for high-performance semiconductors continues to rise, silicon carbide dummy wafers will play a pivotal role in the development and testing of advanced devices. This expansion into new markets underscores the importance of ongoing research and development efforts to enhance the capabilities of silicon carbide wafers.

Silicon carbide dummy wafers play a pivotal role in the semiconductor industry. They ensure efficiency and quality in production processes across various sectors. Their durability and ability to withstand high temperatures make them indispensable for testing and development. These wafers offer the advantage of being cleaned and reused indefinitely, providing cost-effectiveness and sustainability. Future advancements in material science promise to enhance their properties further. As the demand for advanced semiconductor devices grows, silicon carbide dummy wafers will continue to be essential, driving innovation and progress in the industry.

FAQ

What are silicon carbide dummy wafers used for in various industries?

Silicon carbide dummy wafers serve multiple purposes across different sectors. In the semiconductor industry, they are essential for process optimization, testing, and equipment calibration. The photovoltaic industry utilizes them for developing and testing solar cell manufacturing processes. Additionally, these wafers find applications in MEMS, optoelectronics, and RF device manufacturing, where they assist in performance assessment, process development, and equipment evaluation.

What are silicon carbide dummy wafers made of?

These wafers consist of silicon carbide material, renowned for its excellent thermal and electrical conductivity properties. They replicate the shape, size, and physical characteristics of real silicon wafers, making them ideal for various testing and calibration processes.

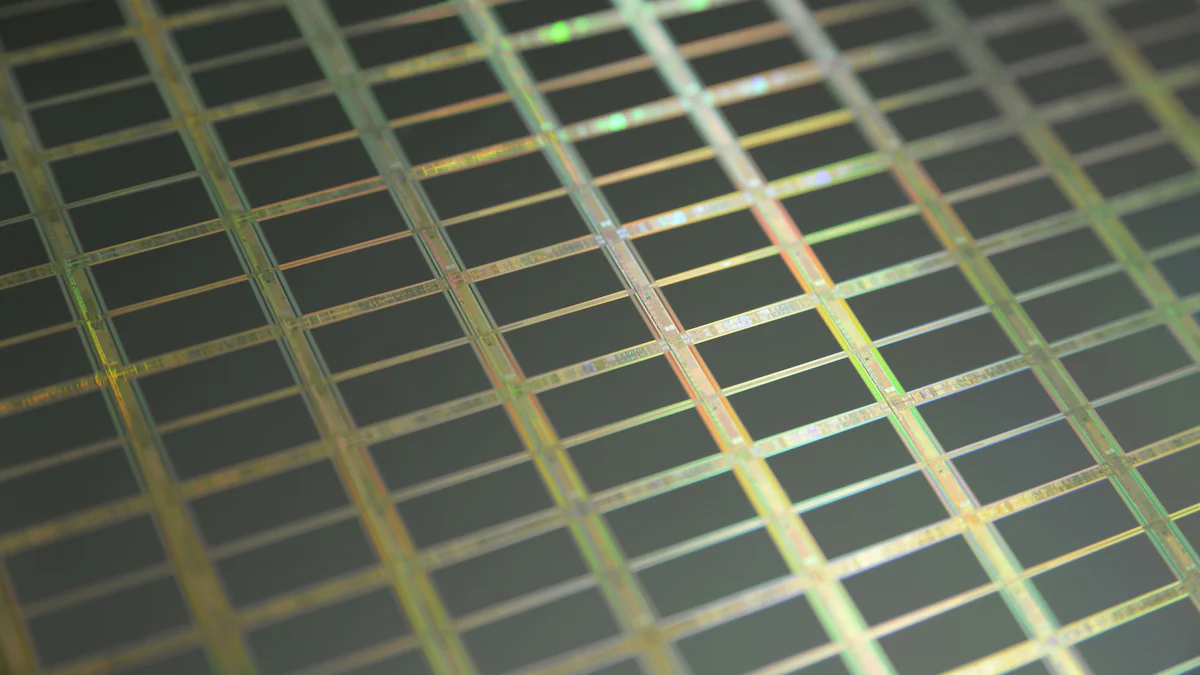

What are the different types of silicon carbide dummy wafers based on size?

Silicon carbide dummy wafers come in various sizes, including 100 mm, 125 mm, 150 mm, and 200 mm. Each size caters to specific applications and requirements within the semiconductor industry, ensuring compatibility with different manufacturing processes.

Are there any companies providing silicon carbide dummy wafers?

Yes, several companies specialize in producing silicon carbide dummy wafers. Ferrotec stands out as a prominent player, focusing on the design, development, and manufacture of advanced materials, components, and systems, including these wafers.

What is the projected value of the global silicon carbide dummy wafer market by 2023?

The global silicon carbide dummy wafer market is expected to surpass a value of $1 billion by 2023. This projection reflects the growing demand and importance of these wafers in various industries, as reported by Market Research Future.

What are premium silicon carbide dummy wafers known for?

Premium silicon carbide dummy wafers are distinguished by their ability to be cleaned and reused indefinitely. This feature enhances their cost-effectiveness and sustainability, making them a preferred choice for manufacturers seeking long-term solutions.

What is the method for manufacturing silicon carbide dummy wafers?

Manufacturers produce these wafers by coating silicon carbide on a graphite substrate using a Chemical Vapor Deposition (CVD) method. The process involves incinerating the graphite substrate to leave only the silicon carbide, followed by adjusting the surface roughness to improve film adhesion and reduce particle generation.

What is the significance of roughening the surface of silicon carbide dummy wafers?

Roughening the surface of these wafers plays a crucial role in suppressing particle generation, improving film thickness, and enhancing the operating rate of the apparatus. Intensive research has demonstrated that this technique significantly boosts the efficiency and reliability of semiconductor manufacturing processes.

What is Electronics & Materials Corp (EMC) known for in the silicon carbide dummy wafer market?

Electronics & Materials Corp (EMC) is a leading provider of materials and components for the semiconductor, display, and solar industries. They offer a wide range of products, including silicon carbide dummy wafers, catering to the diverse needs of these sectors.

What are silicon carbide (SiC) wafers known for?

Silicon carbide (SiC) wafers are recognized for their versatile applications across various industries. Their superior thermal and electrical properties make them indispensable in sectors such as automotive, aerospace, and power electronics, where efficient heat management and high-performance semiconductors are critical.