Have you ever wondered how semiconductors achieve such incredible precision and reliability? One key player behind the scenes is the graphite susceptor. It’s a game-changer in semiconductor production. Why? It offers unmatched thermal stability, ensuring consistent temperatures during critical processes like Chemical Vapor Deposition (CVD). This stability leads to better-quality materials and fewer defects.

Graphite in the production of semiconductors also boosts efficiency. For example, silicon carbide coating on graphite enhances thermal conductivity and chemical resistance. This combination makes it perfect for high-temperature applications. Plus, innovations like pyrolytic graphite coatings add durability, extending the lifespan of these components. With the global graphite susceptor market projected to grow to over $1 billion by 2030, it’s clear this material is shaping the future of semiconductors.

Key Takeaways

- Graphite susceptors stay stable in heat, keeping temperatures steady in semiconductor processes like CVD.

- Coatings like silicon carbide (SiC) make graphite stronger and resistant to chemicals, perfect for high heat uses.

- Using graphite susceptors saves money because they last long and need less fixing than other materials.

- Graphite spreads heat evenly, helping make better semiconductor materials with fewer mistakes.

- Graphite susceptors can be changed to fit different needs, making them important for today’s semiconductor production.

What Are Graphite Susceptors?

Definition and Composition

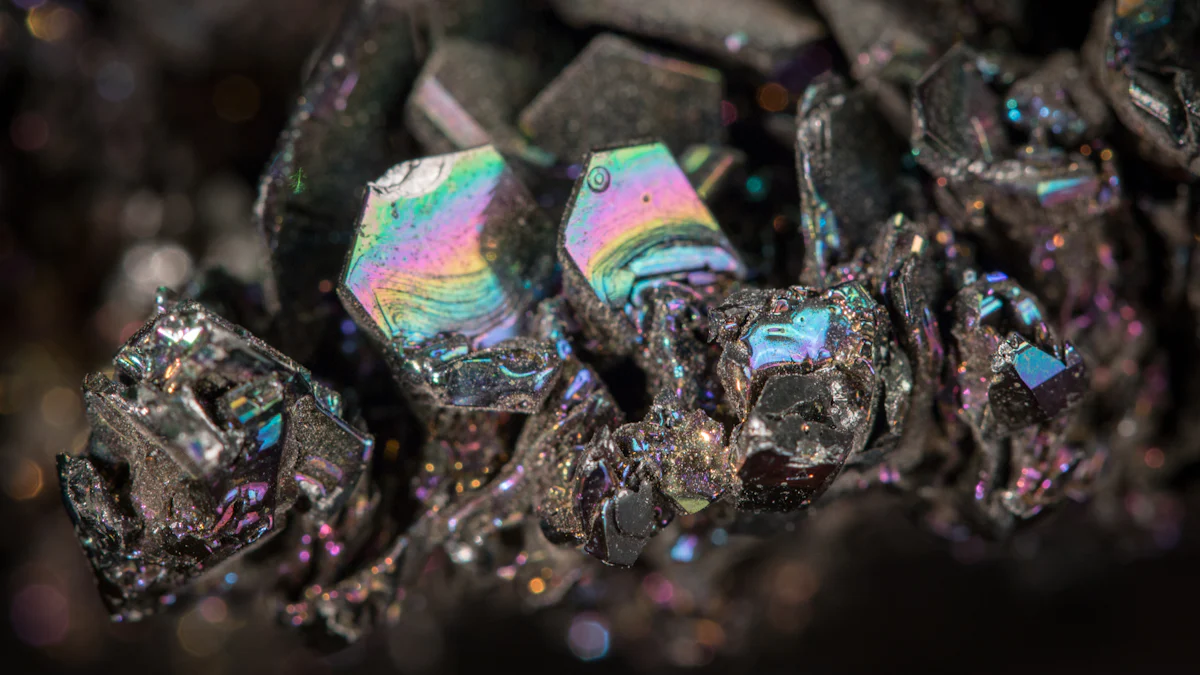

Let’s start with the basics. A graphite susceptor is a specially designed component made from high-quality graphite. It plays a critical role in semiconductor manufacturing. But what makes it so special? It’s all about its composition. Graphite susceptors can be isotropic or anisotropic. Isotropic graphite has uniform properties in every direction, which makes it perfect for applications that demand consistent performance. On the other hand, anisotropic graphite has different properties depending on the direction, making it ideal for specific uses like photovoltaic cell production.

Graphite susceptors are often coated with materials like silicon carbide (SiC). This coating enhances their thermal stability and resistance to corrosion. These features are essential for high-temperature processes like Chemical Vapor Deposition (CVD). In short, the combination of graphite’s natural properties and advanced coatings makes these susceptors incredibly reliable.

Role in Semiconductor Manufacturing

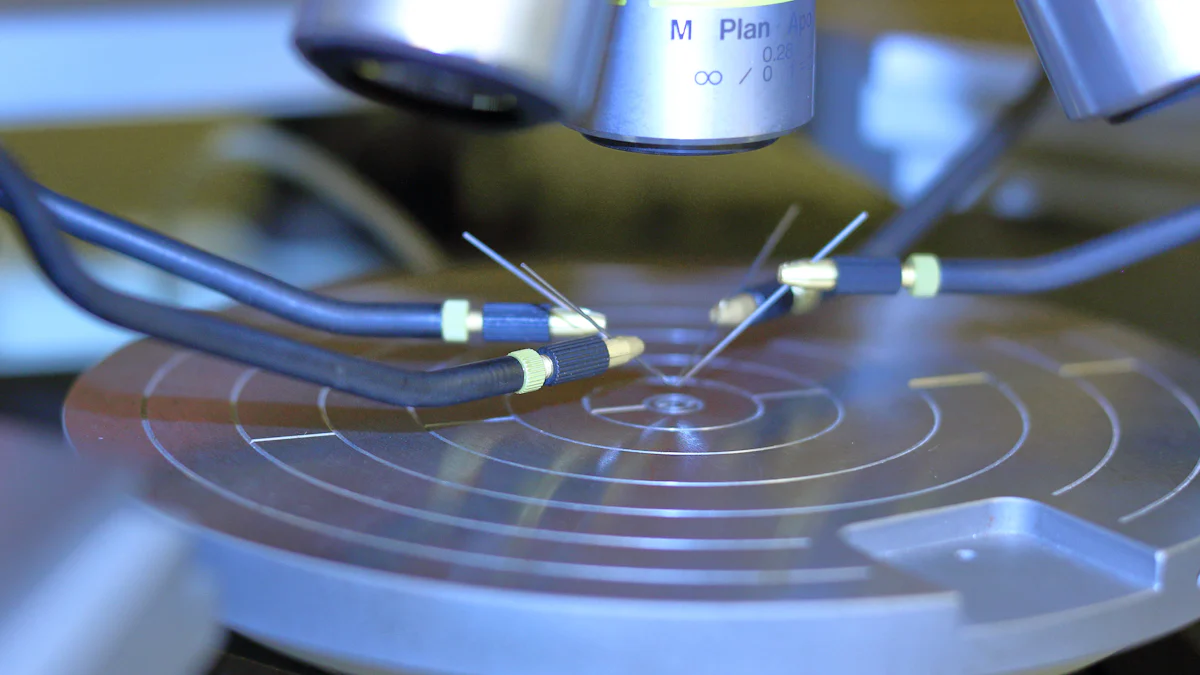

So, what exactly do graphite susceptors do in semiconductor production? They’re like the unsung heroes of the process. Their main job is to support and heat single-crystal substrates during manufacturing. This is especially important in epitaxial deposition, where thin layers of material are grown on a substrate using CVD technology.

Graphite susceptors ensure thermal stability and uniformity throughout the process. This consistency is crucial for growing high-quality materials, like gallium nitride (GaN) thin films used in blue LEDs. Without them, achieving the precision needed for modern semiconductors would be nearly impossible.

Unique Properties of Graphite for Susceptors

Now, let’s talk about why graphite is the go-to material for susceptors. First, it has excellent thermal conductivity, which means it can transfer heat efficiently. It’s also incredibly stable, even at extremely high temperatures. This makes it perfect for the demanding conditions of semiconductor manufacturing.

Graphite can withstand harsh environments, including those with high temperatures and corrosive chemicals. When coated with materials like SiC, its performance improves even further. This combination of natural and enhanced properties ensures that graphite susceptors deliver consistent results, even in the most challenging applications.

Key Benefits of Graphite Susceptors

Thermal Conductivity and Stability

When it comes to thermal conductivity, graphite susceptors are in a league of their own. They transfer heat efficiently, which is critical for processes like epitaxy and Chemical Vapor Deposition (CVD). But here’s the kicker—when coated with silicon carbide (SiC), they become even better. SiC-coated susceptors not only maintain excellent thermal conductivity but also offer superior chemical resistance. This makes them perfect for harsh environments where other materials might fail.

Let me break it down for you:

- Graphite susceptors have great thermal conductivity, ensuring uniform heat distribution.

- SiC coatings enhance their thermal stability, making them more reliable in extreme conditions.

This combination ensures that the manufacturing process runs smoothly, producing high-quality semiconductors with fewer defects.

Durability and Longevity

Durability is another area where graphite susceptors shine. Traditional graphite components might wear out faster, but SiC-coated graphite susceptors take things to the next level. They last longer, require less maintenance, and reduce overall manufacturing costs.

Here’s a quick comparison to show you what I mean:

| Feature | Traditional Graphite | SiC Coated Susceptors |

|---|---|---|

| Lifespan | Shorter lifespan | Extended lifespan |

| Maintenance Costs | Higher | Reduced |

| Manufacturing Expenses | Higher | Lower |

| Performance in MOCVD | Limited | High-quality epitaxy |

These benefits make SiC-coated graphite susceptors the go-to choice for applications like single crystal growth furnaces and epitaxy furnaces. They’re built to handle the demands of modern semiconductor production.

Precision in High-Temperature Environments

Precision is everything in semiconductor manufacturing, especially at high temperatures. Graphite susceptors excel here too. Their thermal stability and uniform conductivity ensure consistent results, even in challenging conditions. This is crucial for processes like MOCVD, where the quality of epitaxial materials depends on precise temperature control.

Adding a SiC coating takes things up a notch. It enhances the durability and chemical stability of the graphite, ensuring it performs reliably under harsh conditions. This combination guarantees uniformity and purity in film materials, which directly impacts the quality of epitaxial wafers. Without this level of precision, producing advanced semiconductors would be nearly impossible.

Cost-Effectiveness

Let’s talk about cost. When it comes to semiconductor production, every dollar counts. That’s why I think graphite susceptors are such a smart choice. They offer a perfect balance of performance and affordability. You get high-quality results without breaking the bank.

Here’s the thing: graphite susceptors last longer, especially when coated with silicon carbide (SiC). This durability means fewer replacements and less downtime. Over time, that adds up to significant savings. Plus, their excellent thermal conductivity ensures efficient energy use. That’s another way they help cut costs.

Now, let’s compare graphite susceptors with other materials. Take a look at this table:

| Material | Advantages | Disadvantages |

|---|---|---|

| Graphite | Good thermal conductivity | Poor chemical resistance |

| Quartz | Excellent thermal stability | Limited mechanical strength |

| CVD SiC Coated | Superior thermal stability | N/A |

| Excellent chemical resistance | N/A | |

| Enhanced durability | N/A |

As you can see, graphite susceptors, especially when coated with SiC, outperform many alternatives. They combine good thermal conductivity with enhanced durability and chemical resistance. Quartz might offer thermal stability, but it lacks the mechanical strength needed for demanding processes.

Here’s what I love most: graphite susceptors deliver premium performance at a fraction of the cost of other high-end materials. They’re a win-win for manufacturers looking to improve efficiency and reduce expenses. Whether it’s for epitaxy or wafer processing, they’re the cost-effective solution the industry needs.

In short, graphite susceptors save money without compromising on quality. That’s why they’re the go-to choice for semiconductor production.

Comparison with Alternative Materials

Graphite vs. Ceramics

When I think about ceramics in semiconductor production, I see their appeal. They’re stable and resistant to high temperatures. But when compared to graphite, ceramics fall short in one key area—thermal conductivity. Graphite, especially thermal pyrolytic graphite, is a powerhouse in this department. It transfers heat much more efficiently than ceramics, which is crucial for processes like epitaxy.

Take a look at this comparison:

| Material | Thermal Conductivity (W/mK) | Comparison to Aluminum | Comparison to Copper |

|---|---|---|---|

| Thermal Pyrolytic Graphite | 1700 | 8X | 4X |

| Ceramics | N/A | N/A | N/A |

Graphite’s ability to conduct heat ensures uniform temperature distribution. This consistency leads to fewer defects in semiconductor devices. Ceramics just can’t match that level of performance.

Graphite vs. Metals

Metals like aluminum and copper are often used in high-temperature applications. But in semiconductor manufacturing, graphite outshines them. Why? It’s all about versatility and performance. Graphite has excellent thermal conductivity, just like metals, but it also offers better electrothermal properties. It can handle high currents and distribute heat evenly, which is critical for precision processes.

Here’s a quick breakdown:

| Advantage | Description |

|---|---|

| Excellent thermal conductivity | Effectively dissipates heat and ensures stable operating temperatures. |

| Good electrothermal properties | Withstands current at high temperatures and provides uniform heat distribution. |

| Outstanding machining properties | Easily processed into complex shapes for precision part manufacturing. |

Graphite is also easier to machine into complex shapes. This makes it perfect for creating custom components like a graphite susceptor. Metals, on the other hand, are harder to work with and may not offer the same level of precision.

Why Graphite Is the Superior Choice

When I compare graphite to ceramics and metals, it’s clear why it’s the top choice for semiconductor production. Graphite combines the best of both worlds. It has the thermal conductivity of metals and the stability of ceramics. Plus, it’s more durable and versatile.

Graphite’s unique properties make it ideal for high-temperature environments. It ensures precision, reduces defects, and lasts longer. Whether it’s for epitaxy or wafer processing, graphite delivers consistent results. That’s why I believe it’s the superior material for semiconductor manufacturing.

If you’re looking for reliability and performance, graphite is the way to go.

Applications in Semiconductor Production

Epitaxy Processes

Epitaxy is one of the most critical steps in semiconductor production, and graphite susceptors play a huge role here. In processes like Metal-Organic Chemical Vapor Deposition (MOCVD), these susceptors support and heat single-crystal substrates. Their quality directly impacts the uniformity and purity of thin film materials. This is essential for high-quality epitaxial growth, which is used to create advanced materials like gallium nitride for LEDs or silicon carbide for power devices.

What makes them so effective? It’s their thermal stability and chemical resistance, especially when coated with silicon carbide (SiC). These coatings allow graphite susceptors to handle the harsh conditions of semiconductor manufacturing. Without them, achieving the precision needed for epitaxy would be nearly impossible.

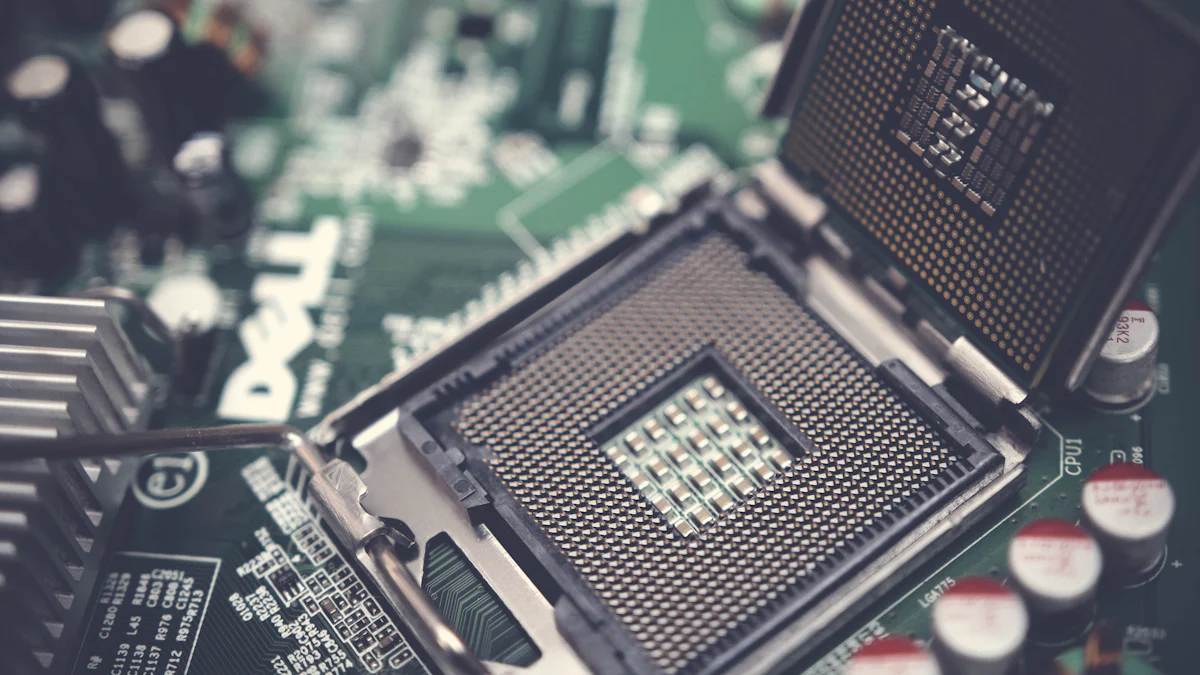

Wafer Processing

When it comes to wafer processing, graphite susceptors are a game-changer. They provide uniform heating, which ensures consistent film quality and thickness. This is crucial for processes like Atomic Layer Deposition (ALD), where even the smallest variation can affect the performance of semiconductor devices.

Here’s how they enhance wafer processing:

- They deliver excellent thermal stability, maintaining consistent temperatures.

- They ensure precise control over deposition processes, improving film quality.

- SiC-coated susceptors withstand harsh conditions, protecting the wafer during fabrication.

These features make graphite susceptors indispensable for modern wafer processing. They help manufacturers produce reliable and high-performing semiconductor devices.

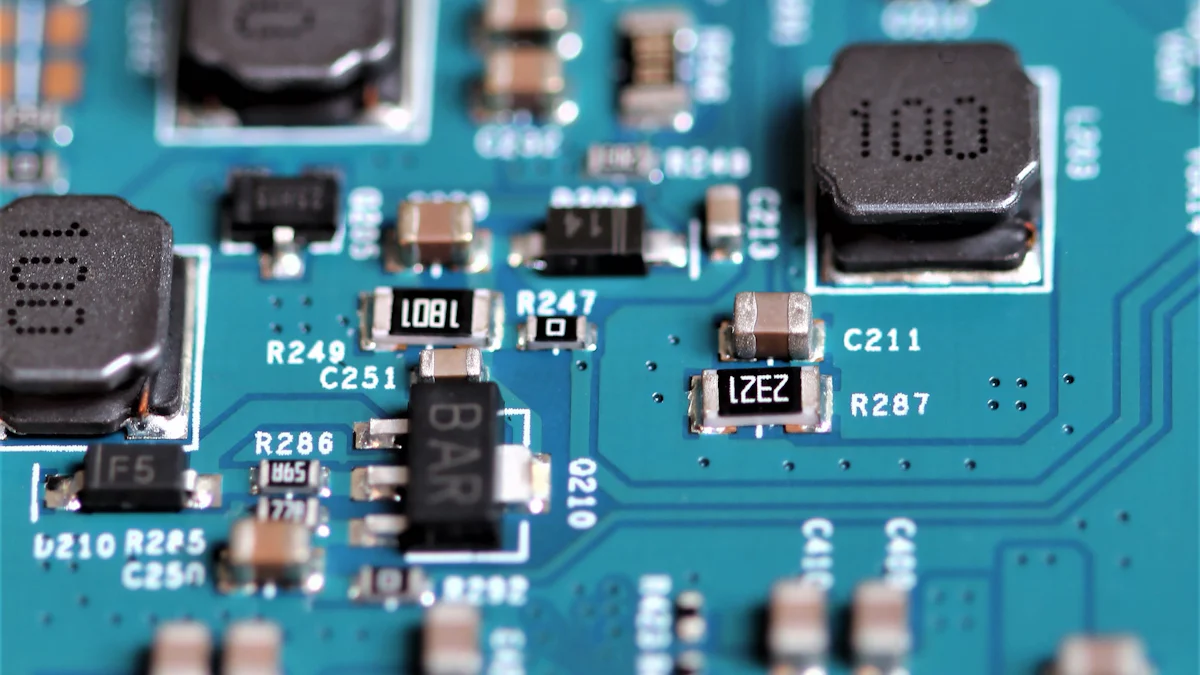

High-Temperature Applications in Semiconductor Manufacturing

High-temperature environments are common in semiconductor production, and graphite susceptors excel in these conditions. They manage heat efficiently, ensuring uniform temperature distribution across the substrate. This is vital for processes like epitaxy and CVD, where precision is everything.

Their high thermal stability and resistance to chemical erosion make them perfect for demanding applications. Whether it’s handling extreme temperatures or corrosive chemicals, graphite susceptors deliver consistent performance. This reliability helps manufacturers maintain the quality and efficiency of their production lines.

In short, graphite susceptors are the backbone of high-temperature applications. They ensure precision, durability, and efficiency, making them a must-have for semiconductor production.

Graphite susceptors bring unmatched advantages to semiconductor production. Their thermal stability ensures consistent temperatures, while their chemical resistance protects wafers during fabrication. SiC or TaC coatings enhance these properties, enabling precise temperature control and maintaining high-purity environments. These features make them essential for producing high-quality materials with fewer defects.

Looking ahead, the demand for graphite susceptors will only grow. With advancements in processes like CVD and MBE, and the rise of electric vehicles, their role in semiconductor technology will expand. I see them driving innovation and shaping the future of electronics.

The graphite susceptor isn’t just a component—it’s a cornerstone of modern semiconductor manufacturing.

FAQ

What is a graphite susceptor used for in semiconductor production?

Graphite susceptors heat and support substrates during processes like epitaxy and Chemical Vapor Deposition (CVD). They ensure precise temperature control, which is critical for creating high-quality semiconductor materials.

Why is silicon carbide (SiC) coating important for graphite susceptors?

SiC coatings enhance the thermal stability and chemical resistance of graphite susceptors. This makes them more durable and reliable, especially in high-temperature or corrosive environments.

How do graphite susceptors improve manufacturing efficiency?

They provide uniform heat distribution and last longer than many alternatives. This reduces defects, minimizes downtime, and lowers maintenance costs, making the entire process more efficient.

Are graphite susceptors environmentally friendly?

Yes! Graphite susceptors are durable and reusable, which reduces waste. Their energy efficiency also helps lower the environmental impact of semiconductor production.

Can graphite susceptors be customized for specific applications?

Absolutely! Graphite is easy to machine into complex shapes. This makes it perfect for creating custom susceptors tailored to unique manufacturing needs.