Tantalum carbide stands as a marvel in material science due to its extraordinary physical and chemical properties. With a melting point exceeding 3,800°C, it outperforms most materials in extreme heat environments. Its exceptional hardness, ranking just below diamond, makes it indispensable for applications requiring durability and wear resistance. Additionally, its remarkable chemical stability ensures resilience against corrosion and oxidation. These unique attributes position tantalum carbide as a critical material in industries that demand high performance under the most challenging conditions.

Key Takeaways

- Tantalum carbide boasts an extraordinary melting point exceeding 3,800°C, making it ideal for extreme heat applications in aerospace and defense.

- Its exceptional hardness, ranking just below diamond, enhances the durability of cutting tools and machining equipment, leading to cost savings and increased efficiency.

- The material's remarkable chemical stability ensures it remains resistant to corrosion and oxidation, making it suitable for harsh chemical environments.

- Tantalum carbide is a key additive in tungsten carbide composites, improving wear resistance and preventing grain growth for optimal performance.

- In electronics, tantalum carbide serves as a diffusion barrier and heat dissipation component, ensuring reliability in high-temperature devices.

- Its unique properties position tantalum carbide as a 'super material,' essential for advancing high-performance materials across various industries.

- Understanding the synthesis methods of tantalum carbide can help industries customize its properties for specific applications, enhancing its versatility.

What Is Tantalum Carbide and Why Is It Significant?

Defining Tantalum Carbide

Composition and Structure of Tantalum Carbide

Tantalum carbide, often abbreviated as TaC, is a compound formed by tantalum and carbon atoms. It belongs to the family of transition metal carbides, which are known for their exceptional physical and chemical properties. The material exhibits a crystalline structure, specifically a face-centered cubic lattice, which contributes to its remarkable hardness and thermal stability. This unique arrangement of atoms allows tantalum carbide to withstand extreme conditions, making it a preferred choice in demanding applications.

The compound's chemical formula, TaC, reflects its stoichiometric balance, although variations in carbon content can occur. These variations slightly alter its properties, enabling customization for specific industrial needs. Its density, approximately 14.5 g/cm³, further highlights its robustness and suitability for high-performance environments.

How Tantalum Carbide Is Synthesized

The synthesis of tantalum carbide typically involves high-temperature reactions between tantalum and carbon sources. One common method includes the direct reaction of tantalum metal powder with carbon black in a controlled atmosphere. This process requires temperatures exceeding 2,000°C to ensure complete formation of the compound.

Another approach involves carbothermal reduction, where tantalum oxide reacts with carbon at elevated temperatures. This method not only produces tantalum carbide but also minimizes impurities, resulting in a high-purity product. Advanced techniques, such as chemical vapor deposition (CVD), are also employed to create thin films or coatings of tantalum carbide for specialized applications, including electronics and aerospace components.

Importance in Material Science

Role in Advancing High-Performance Materials

Tantalum carbide plays a pivotal role in the development of high-performance materials. Its exceptional hardness, comparable to diamond, enhances the durability of cutting tools and machining equipment. When added to tungsten carbide composites, tantalum carbide improves wear resistance and prevents grain growth, ensuring optimal performance under extreme conditions.

In the field of electronics, tantalum carbide contributes to the creation of diffusion barriers and heat dissipation components. These applications leverage its excellent thermal conductivity and chemical stability, which are essential for maintaining the integrity of electronic devices in high-temperature environments. Additionally, its use in optical coatings enhances the durability and efficiency of lenses and mirrors exposed to harsh conditions.

Why It Is Considered a "Super Material"

Tantalum carbide earns its reputation as a "super material" due to its unparalleled combination of properties. Its melting point, exceeding 3,800°C, ranks among the highest of any known material, enabling it to perform reliably in extreme heat environments. This characteristic makes it indispensable in aerospace and defense industries, where materials must endure intense thermal stress.

The compound's chemical stability further solidifies its status as a super material. It resists corrosion from acids and other aggressive chemicals, ensuring longevity in chemically harsh environments. Moreover, its electrical conductivity and thermal shock resistance expand its utility across diverse sectors, from semiconductors to industrial manufacturing. These attributes collectively position tantalum carbide as a cornerstone of modern material science.

Unique Properties of Tantalum Carbide

Exceptional Heat Resistance

Melting Point Exceeding 3800°C

Tantalum carbide exhibits an extraordinary melting point, surpassing 3,800°C. This characteristic places it among the materials with the highest known melting points. Such thermal resilience stems from its robust atomic structure, which maintains stability even under extreme heat. This property makes tantalum carbide indispensable in applications requiring materials to endure intense thermal stress without degradation.

"Tantalum carbide's melting point exceeds 3,800°C, making it a critical material for high-temperature environments," as noted in various industrial studies.

Its ability to retain strength and integrity at temperatures between 2,900°C and 3,200°C further enhances its utility in demanding sectors like aerospace and defense.

Applications in Extreme Heat Environments

The exceptional heat resistance of tantalum carbide finds extensive use in extreme heat environments. In aerospace engineering, it serves as a key material for thermal protection systems in hypersonic vehicles. These systems must withstand the intense heat generated during high-speed atmospheric reentry. Jet engines and spacecraft components also benefit from tantalum carbide's ability to endure prolonged exposure to extreme temperatures.

In manufacturing, tantalum carbide plays a vital role in high-temperature furnaces and reactors. Its stability ensures consistent performance, even in the most challenging thermal conditions. These applications highlight its importance in industries where heat resistance is paramount.

Extreme Hardness

Ranking on the Mohs Scale and Wear Resistance

Tantalum carbide ranks just below diamond on the Mohs scale of hardness, showcasing its exceptional mechanical strength. This extreme hardness enables it to resist wear and abrasion, making it ideal for applications requiring durability. Its crystalline structure contributes to this property, ensuring long-lasting performance in environments where other materials may fail.

The material's wear resistance extends its lifespan in tools and components subjected to constant friction. This quality makes tantalum carbide a preferred choice for enhancing the durability of cutting tools and machining equipment.

Durability in Cutting and Machining Tools

Tantalum carbide's hardness and wear resistance make it a cornerstone in the production of cutting and machining tools. It is often added to tungsten carbide composites to improve their physical properties. This combination enhances the tools' ability to cut through tough materials while maintaining sharpness over extended periods.

In industrial settings, tantalum carbide extends the life of tools used in drilling, milling, and grinding. Its mechanical resilience reduces the frequency of tool replacement, leading to cost savings and increased efficiency. These advantages underscore its value in manufacturing processes.

Remarkable Chemical Stability

Insolubility in Water and Resistance to Acids

Tantalum carbide demonstrates remarkable chemical stability, remaining insoluble in water and resistant to most acids. This resistance ensures its longevity in chemically aggressive environments. Unlike many materials that degrade when exposed to corrosive substances, tantalum carbide retains its structural integrity.

This property makes it suitable for use in environments where exposure to harsh chemicals is unavoidable. Its stability ensures consistent performance, even under prolonged chemical stress.

Performance in Chemically Aggressive Environments

The chemical stability of tantalum carbide enables its use in chemically aggressive environments. In industrial applications, it serves as a protective coating for components exposed to corrosive agents. This coating prevents damage and extends the lifespan of the underlying material.

In the electronics industry, tantalum carbide acts as a diffusion barrier, protecting sensitive components from chemical contamination. Its ability to withstand both thermal and chemical stress makes it a versatile material for various high-performance applications.

Applications of Tantalum Carbide in Industry

Aerospace and Defense

Use in Thermal Protection Systems for Hypersonic Vehicles

Hypersonic vehicles, traveling at speeds exceeding Mach 5, generate extreme heat during atmospheric reentry. Tantalum Carbide plays a critical role in thermal protection systems for these vehicles. Its exceptional heat resistance, with a melting point surpassing 3,800°C, ensures structural integrity under intense thermal stress. Engineers utilize it as a coating material for components exposed to high temperatures, such as leading edges and nose cones. This application enhances the durability and performance of hypersonic vehicles, enabling safe and efficient operation in extreme conditions.

Applications in Jet Engines and Spacecraft

Jet engines and spacecraft demand materials capable of withstanding high temperatures and corrosive environments. Tantalum Carbide serves as a coating for turbine blades and rocket nozzles, where it provides superior thermal stability and resistance to oxidation. Its ability to endure prolonged exposure to extreme heat makes it indispensable in aerospace engineering. Additionally, its chemical stability ensures that critical components maintain their performance even in chemically aggressive atmospheres, such as those encountered in space exploration.

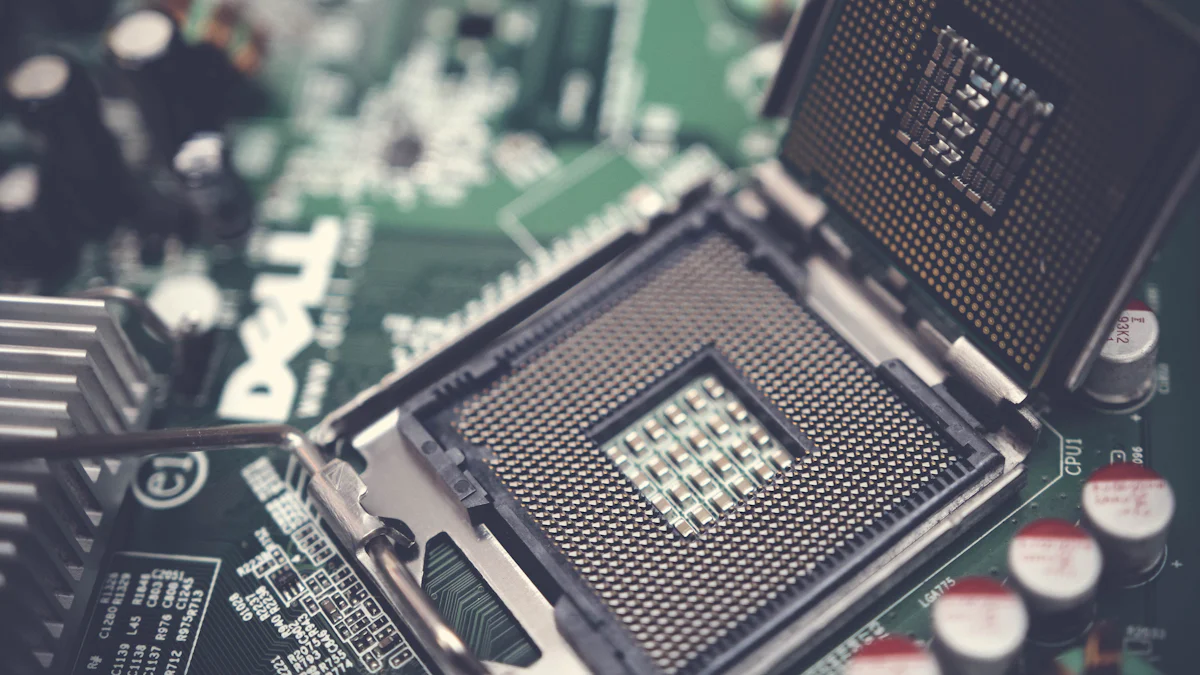

Electronics and Semiconductors

Role in Electrical Contacts and Diffusion Barriers

In the electronics industry, Tantalum Carbide is widely used for its excellent electrical conductivity and chemical stability. It acts as a diffusion barrier in semiconductor devices, preventing the migration of materials that could compromise the functionality of electronic components. Its high thermal conductivity also aids in heat dissipation, ensuring the reliability of electrical contacts in high-temperature environments. These properties make it a preferred choice for advanced electronic applications, including microchips and integrated circuits.

Use in High-Temperature Electronic Components

High-temperature electronic components, such as those used in power systems and industrial machinery, benefit from the unique properties of Tantalum Carbide. Its resistance to wear and corrosion ensures long-lasting performance, even under harsh operating conditions. Manufacturers incorporate it into components like resistors and capacitors to enhance their durability and efficiency. This application highlights its versatility and importance in modern electronics.

Manufacturing and Cutting Tools

Enhancing Tungsten Carbide Composites

Tantalum Carbide is a key additive in tungsten carbide composites, which are widely used in cutting tools. By improving the physical properties of these composites, it enhances their hardness, wear resistance, and high-temperature strength. This addition prevents grain growth during sintering, resulting in a more robust and reliable material. Industries such as automotive and aerospace rely on these enhanced composites for precision machining and manufacturing processes.

Extending Tool Life in Machining Applications

Cutting tools and machining equipment face constant wear and tear during operation. Tantalum Carbide extends the lifespan of these tools by providing exceptional hardness and resistance to abrasion. It is often used as a coating for tool bits, ensuring sharpness and durability over extended periods. This reduces the frequency of tool replacement, leading to cost savings and increased productivity in industrial settings. Its role in machining applications underscores its value in the manufacturing sector.

How Does Tantalum Carbide Compare to Other Materials?

Comparison to Other Carbides (e.g., Tungsten Carbide, Silicon Carbide)

Advantages in Heat Resistance and Hardness

Tantalum carbide surpasses many other carbides in heat resistance and hardness. Its melting point, exceeding 3,800°C, outperforms tungsten carbide and silicon carbide, which have lower thermal thresholds. This exceptional heat resistance allows tantalum carbide to maintain structural integrity in extreme environments where other materials may fail.

In terms of hardness, tantalum carbide ranks just below diamond, making it harder than tungsten carbide and silicon carbide. This superior hardness enhances its wear resistance, ensuring durability in applications such as cutting tools and machining equipment. These properties make tantalum carbide a preferred choice for industries requiring materials that can endure both high temperatures and mechanical stress.

"Tantalum carbide's combination of high melting point and exceptional hardness makes it indispensable in high-performance applications," as noted in material science research.

Differences in Cost and Availability

While tantalum carbide offers unmatched performance, its cost and availability differ significantly from other carbides. Tungsten carbide, for instance, is more abundant and less expensive, making it a common choice for general-purpose applications. Silicon carbide, known for its affordability and versatility, is widely used in electronics and abrasives.

Tantalum carbide, however, is less readily available due to the limited supply of tantalum, a rare transition metal. This scarcity increases its cost, restricting its use to specialized applications where its unique properties justify the expense. Industries prioritize tantalum carbide for critical components where performance outweighs cost considerations.

Comparison to Ceramics and Metals

Superior Performance in Extreme Conditions

Tantalum carbide outperforms traditional ceramics and metals in extreme conditions. Unlike ceramics, which can become brittle under mechanical stress, tantalum carbide retains its toughness and structural integrity. Its high melting point and chemical stability enable it to withstand intense heat and corrosive environments, surpassing the capabilities of most metals.

Metals, while ductile and versatile, often lack the hardness and wear resistance of tantalum carbide. For example, steel and titanium alloys degrade more quickly in high-temperature or chemically aggressive settings. Tantalum carbide's ability to resist oxidation and corrosion ensures long-term performance in environments where metals may fail.

Trade-Offs in Manufacturing and Processing

Despite its advantages, tantalum carbide presents challenges in manufacturing and processing. Its extreme hardness, while beneficial for durability, complicates machining and shaping processes. Manufacturers require advanced techniques, such as chemical vapor deposition or sintering, to produce components with precision.

In contrast, metals and ceramics are easier to process and mold into complex shapes. This ease of fabrication makes them more suitable for applications where intricate designs are necessary. However, the trade-off lies in their reduced performance under extreme conditions. Tantalum carbide's superior properties often justify the additional effort and cost involved in its production.

Tantalum carbide stands as a cornerstone in material science, offering unmatched heat resistance, exceptional hardness, and remarkable chemical stability. These properties make it indispensable in industries such as aerospace, electronics, and manufacturing, where performance under extreme conditions is critical. Its applications range from thermal protection systems in hypersonic vehicles to cutting tools with extended durability. As technological advancements continue, tantalum carbide will remain pivotal in driving innovation and enhancing the capabilities of high-performance materials across various sectors.

FAQ

What are the properties and applications of tantalum carbide?

Tantalum carbide exhibits exceptional hardness and heat resistance, making it a highly sought-after material in industrial applications. It is a refractory ceramic with one of the highest known melting points, exceeding 3,800°C. This property makes it ideal for use in cutting tools, where durability and wear resistance are critical. Additionally, tantalum carbide serves as a fine-crystalline additive in tungsten carbide alloys, enhancing their performance in demanding environments.

How is tantalum carbide used in industrial applications?

Industries utilize tantalum carbide to improve the physical properties of materials and components. It is commonly added to tungsten carbide/cobalt (WC/Co) powders to enhance the strength and wear resistance of sintered products. Manufacturers also apply tantalum carbide as a coating to protect surfaces from abrasion and corrosion. In steel molds used for aluminum alloy injection molding, it ensures durability and precision under high-stress conditions.

What are the key properties of tantalum carbide powder?

Tantalum carbide powder is renowned for its ability to withstand extreme conditions. It endures temperatures up to 3,800°C and possesses hardness comparable to diamonds. When used as a grain refiner in tungsten-based hard alloys, it significantly enhances the material's mechanical properties. These qualities make tantalum carbide powder indispensable in applications requiring high performance and reliability.

What has nanoparticle research discovered about tantalum carbide?

Nanoparticle research has revealed fascinating insights into tantalum carbide's behavior at the atomic and molecular levels. Altering its properties at the nanoscale has unlocked new potential in various fields, including biomedicine, electronics, and ceramics. These advancements demonstrate how modifying basic elements can lead to innovative applications and improved material performance.

"Nanoparticle research has shown that even small changes in atomic structure can yield significant benefits across multiple industries," according to material science studies.

Why is tantalum carbide considered a "super material"?

Tantalum carbide earns its reputation as a "super material" due to its unparalleled combination of properties. Its extreme hardness, high melting point, and chemical stability enable it to perform reliably in harsh environments. These attributes make it indispensable in aerospace, electronics, and manufacturing industries, where materials must endure intense thermal, mechanical, and chemical stress.

How does tantalum carbide enhance tungsten carbide/cobalt alloys?

Tantalum carbide improves the physical properties of tungsten carbide/cobalt (WC/Co) alloys by acting as a grain refiner. It prevents grain growth during the sintering process, resulting in a more robust and wear-resistant material. This enhancement ensures that tools and components made from these alloys maintain their performance and longevity, even under extreme conditions.

What role does tantalum carbide play in cutting tools?

Tantalum carbide is a critical component in cutting tools due to its exceptional hardness and wear resistance. It is often combined with tungsten carbide to create composites that can cut through tough materials with precision. These tools retain their sharpness over extended periods, reducing the need for frequent replacements and improving efficiency in industrial operations.

Can tantalum carbide be used in high-temperature environments?

Yes, tantalum carbide is specifically designed for high-temperature applications. Its melting point exceeds 3,800°C, allowing it to maintain structural integrity in extreme heat. This property makes it a preferred choice for aerospace components, such as thermal protection systems in hypersonic vehicles, and for industrial furnaces and reactors.

What makes tantalum carbide chemically stable?

Tantalum carbide resists corrosion and oxidation due to its remarkable chemical stability. It remains insoluble in water and withstands exposure to most acids, ensuring durability in chemically aggressive environments. This stability makes it suitable for protective coatings and diffusion barriers in electronics and industrial applications.

How does tantalum carbide contribute to advancements in material science?

Tantalum carbide drives innovation in material science by enabling the development of high-performance materials. Its unique properties, such as extreme hardness and heat resistance, expand the possibilities for creating durable and efficient components. From aerospace engineering to semiconductor manufacturing, tantalum carbide continues to push the boundaries of what materials can achieve.