Tantalum carbide (TaC) coatings, including the Momentive TAC coating, play a critical role in modern industrial applications. Their exceptional wear resistance, high melting point, and ability to withstand extreme temperatures make them indispensable in sectors like aerospace, automotive, and semiconductor manufacturing. The global TaC coating market, valued at USD 1.42 billion in 2022, is expected to reach USD 2.55 billion by 2030, growing at a CAGR of 7.5%. Similarly, the Momentive TAC coating market is projected to grow significantly, with an estimated CAGR of 17.9% from 2025 to 2031. These coatings, especially when applied as TAC coating on graphite, enhance durability and performance, making them a preferred choice for high-performance applications. Additionally, TaC-coated Graphite for sale is becoming increasingly popular among stakeholders looking to capitalize on emerging opportunities. It is essential for stakeholders to stay informed about these trends to maximize their potential in the market.

Key Takeaways

- Momentive TaC coatings are important for aerospace and car industries. They are strong and can handle high heat.

- The global TaC coating market may grow from USD 1.42 billion in 2022 to USD 2.55 billion by 2030. This shows high demand.

- New technology like CVD and PVD makes TaC coatings work better and be more useful.

- Companies now focus on eco-friendly coatings to help the environment.

- Growing markets have big chances for success, especially in green energy and electronics.

Market Overview

Current Market Size and Growth Rate

The current market for Momentive TaC coatings has shown remarkable growth due to increasing demand for high-performance materials. I have observed that industries such as aerospace and automotive are driving this demand. These coatings offer excellent wear resistance, a high melting point, and superior hardness, making them ideal for high-temperature and high-wear conditions.

Several factors influence the market's growth rate:

- The aerospace industry in North America uses these coatings to protect aircraft components.

- The automotive sector relies on them for wear protection and performance enhancement.

- Advanced manufacturing industries in North America and Europe contribute significantly to market expansion.

- Rapid industrialization in the Asia-Pacific region further fuels demand.

The focus on reducing wear and corrosion has also played a pivotal role in the market's steady growth.

Projected Market Size for 2025

The Momentive TaC coating market is poised for substantial growth in the coming years. By 2025, the market is projected to reach approximately USD 45.4 million. This growth trajectory is based on a compound annual growth rate (CAGR) of 17.9% from 2025 to 2031. I believe this projection reflects the increasing adoption of these coatings across various industries. Their ability to enhance durability and performance makes them a preferred choice for stakeholders.

Industries Driving Demand for Momentive TaC Coating

The demand for Momentive TaC coatings spans multiple industries. I have summarized the key industries and their reasons for demand in the table below:

| Region | Industries Driving Demand | Reasons for Demand |

|---|---|---|

| North America | Aerospace, Automotive, Oil & Gas | Protects components from wear and corrosion |

| Europe | Automotive, Medical, Manufacturing | Protects tools, medical devices, and improves performance |

| Asia Pacific | Aerospace, Automotive, Electronics | Protects components in aircraft and electronic devices |

| Latin America | Automotive, Oil & Gas, Medical | Protects components in cars and medical devices |

These industries rely on Momentive TaC coatings to improve the longevity and efficiency of their products. The aerospace and electronics sectors, in particular, benefit from the coatings' ability to withstand extreme conditions.

Key Drivers of Market Growth

Advancements in Coating Technologies

Advancements in coating technologies have significantly contributed to the growth of the Momentive TaC coating market. I have observed that new entrants and investments are reshaping the industry. These developments bring innovative techniques and materials, enhancing the performance and application of TaC coatings.

| Advancements in TaC Coating Technologies | Description |

|---|---|

| New Entrants | Introduction of innovative companies into the market |

| New Investments | Increased funding and resources allocated to TaC coating technologies |

| Innovations | Development of new techniques and materials in TaC coatings |

These advancements ensure that the coatings meet the evolving demands of industries, particularly in high-performance applications. I believe this continuous innovation will drive the market forward.

Demand in High-Temperature Applications

The demand for TaC coatings in high-temperature applications is another key growth driver. Their exceptional wear resistance, high melting point, and superior hardness make them indispensable in industries like aerospace and semiconductor manufacturing.

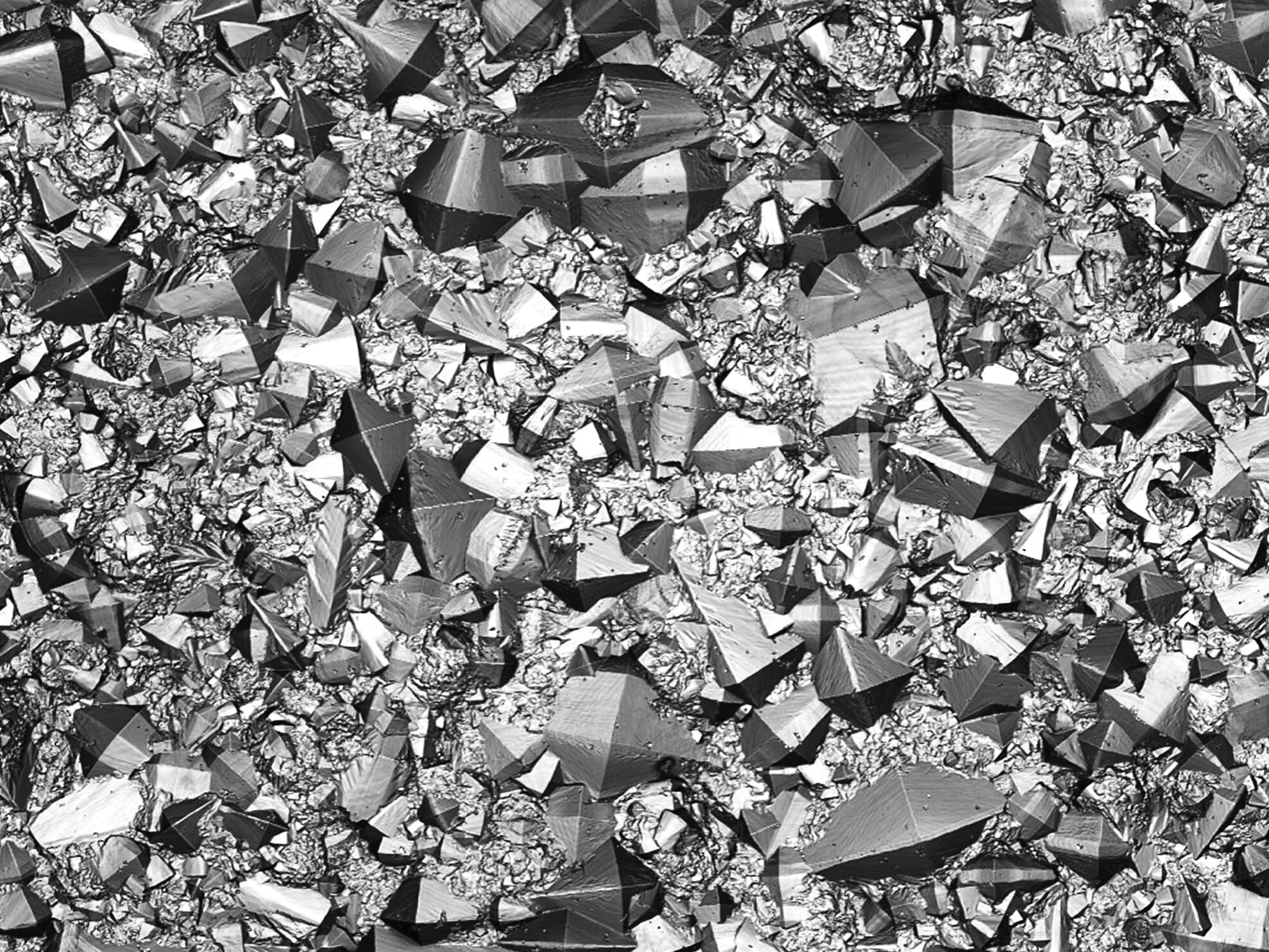

- Tantalum carbide (TaC) has a melting point of 3950 °C and hardness ranging from 15-19 GPa.

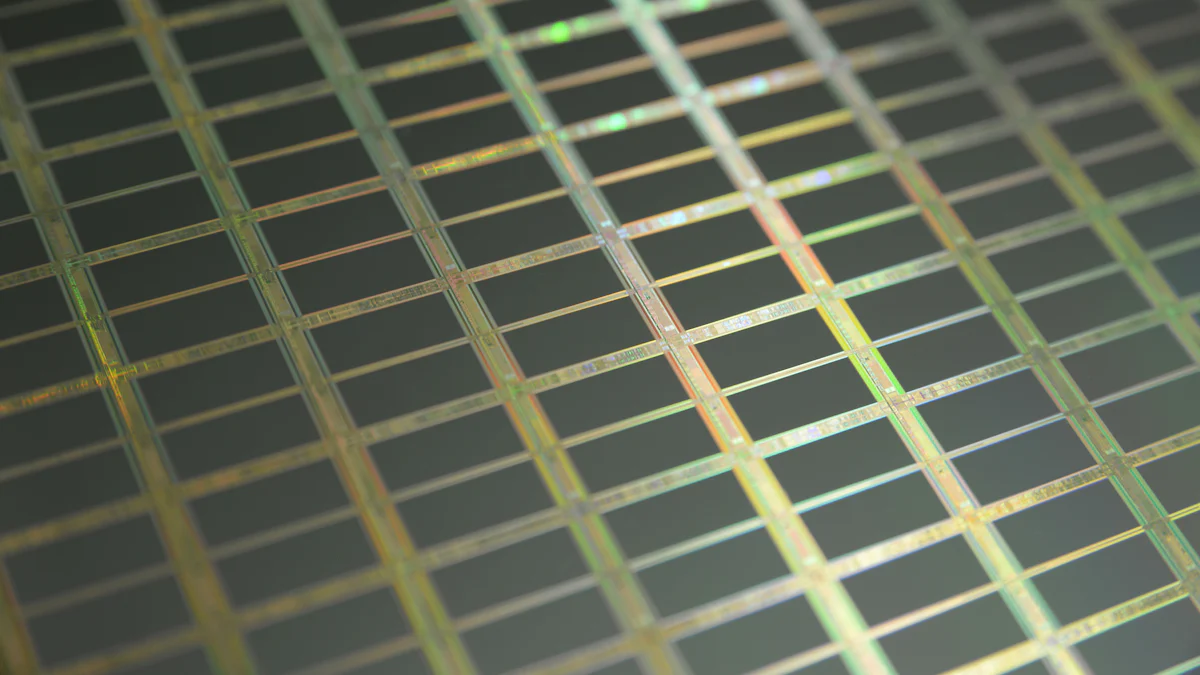

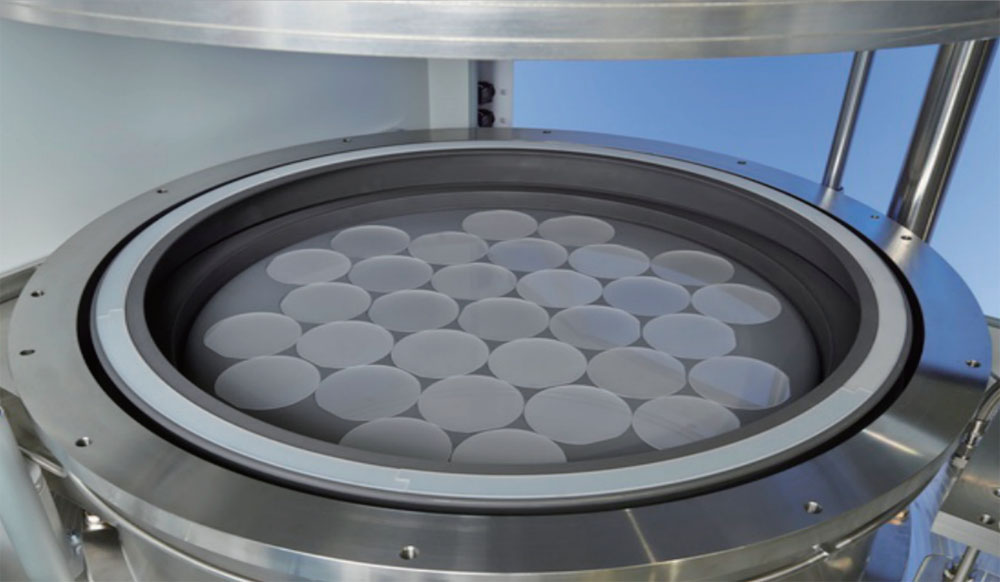

- It protects graphite components in semiconductor processing, extending their lifespan and improving performance.

- TaC coatings maintain reaction stoichiometry and inhibit impurity migration, which is critical in extreme conditions.

These properties make Momentive TaC coatings ideal for high-temperature environments. I see this as a major factor fueling their adoption across various sectors.

Growth in Aerospace, Automotive, and Electronics

The aerospace, automotive, and electronics industries play a pivotal role in driving the growth of the Momentive TaC coating market. These industries rely on the coatings' high hardness and thermal stability for critical applications.

- The aerospace sector uses TaC coatings to protect aircraft components from wear and corrosion.

- The automotive industry employs these coatings to enhance the durability and performance of car components.

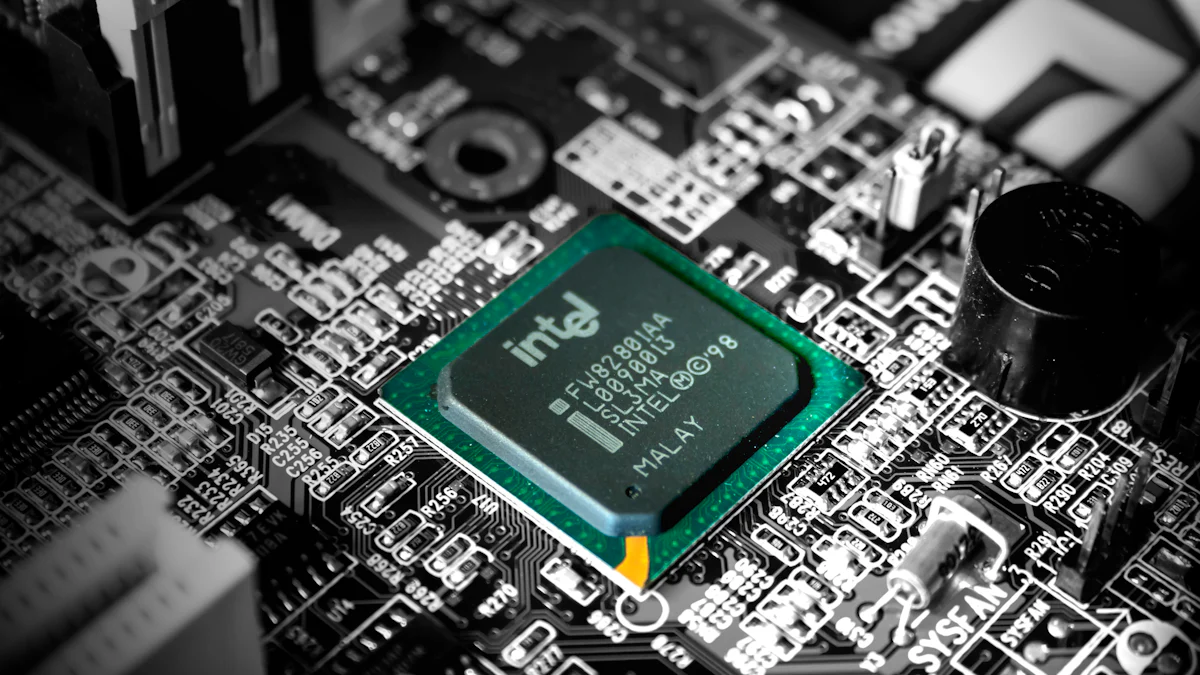

- The electronics industry benefits from TaC coatings by safeguarding sensitive components, especially in the Asia-Pacific region.

I have noticed that the growing focus on high-performance vehicles and advanced electronic devices further accelerates the demand for these coatings. The Momentive TaC coating market is well-positioned to capitalize on these trends.

Focus on Durability and Corrosion Resistance

Durability and corrosion resistance are two critical factors that drive the adoption of advanced coatings in industrial applications. I have observed that industries today demand materials that can withstand harsh environments while maintaining their structural integrity. Momentive TaC coatings excel in meeting these requirements, making them a preferred choice for high-performance applications.

The exceptional durability of these coatings stems from their unique composition. Tantalum carbide, known for its extreme hardness and high melting point, forms a protective layer that resists wear and tear. This feature ensures that components coated with Momentive TaC maintain their functionality even under intense mechanical stress. For instance, in the aerospace sector, these coatings protect turbine blades and other critical parts from degradation caused by friction and high temperatures.

Corrosion resistance is another standout feature of Momentive TaC coatings. I have seen how industries like oil and gas, where exposure to corrosive chemicals is common, benefit from this property. The coatings act as a barrier, preventing chemical reactions that could weaken the underlying material. This not only extends the lifespan of components but also reduces maintenance costs, a significant advantage for businesses.

In my experience, the combination of durability and corrosion resistance makes Momentive TaC coatings indispensable across various sectors. Their ability to enhance the performance and longevity of industrial components ensures their continued demand in the market. As industries prioritize efficiency and reliability, I believe these coatings will play an even more prominent role in the future.

Market Segmentation

By Application

Aerospace and Defense

I have seen how aerospace and defense industries rely heavily on Momentive TaC coatings for their exceptional durability and resistance to extreme conditions. These coatings protect critical components like turbine blades and engine parts from wear and corrosion. Their ability to withstand high temperatures ensures the longevity and reliability of aircraft and defense equipment.

Automotive

In the automotive sector, Momentive TaC coatings enhance the performance and lifespan of components such as brake pads and gears. These coatings reduce wear and corrosion, which is essential for maintaining vehicle efficiency. I believe their application in high-performance vehicles will continue to grow as the industry prioritizes durability and reliability.

Electronics and Semiconductors

The electronics industry benefits significantly from the protective properties of these coatings. They safeguard sensitive components from wear and corrosion, ensuring optimal performance. In my experience, the Asia-Pacific region, with its dominance in electronics manufacturing, drives much of this demand.

Other Industrial Applications

Beyond the primary industries, Momentive TaC coatings find applications in medical, manufacturing, and oil & gas sectors. For instance, they protect surgical instruments, manufacturing tools, and drilling equipment from wear and corrosion. The versatility of these coatings makes them indispensable across various industrial applications.

| Industry | Applications |

|---|---|

| Aerospace | Protecting components in aircraft from wear and corrosion, including turbine blades and engine components. |

| Automotive | Protecting components in cars, such as brake pads and gears, from wear and corrosion, while improving performance. |

| Medical | Protecting medical implants and devices, including surgical instruments and orthopedic implants, from wear and corrosion. |

| Manufacturing | Protecting tools and components in manufacturing from wear and corrosion. |

| Oil & Gas | Protecting components in oil & gas drilling equipment from wear and corrosion. |

| Electronics | Protecting electronic components from wear and corrosion. |

By Technology

Chemical Vapor Deposition (CVD)

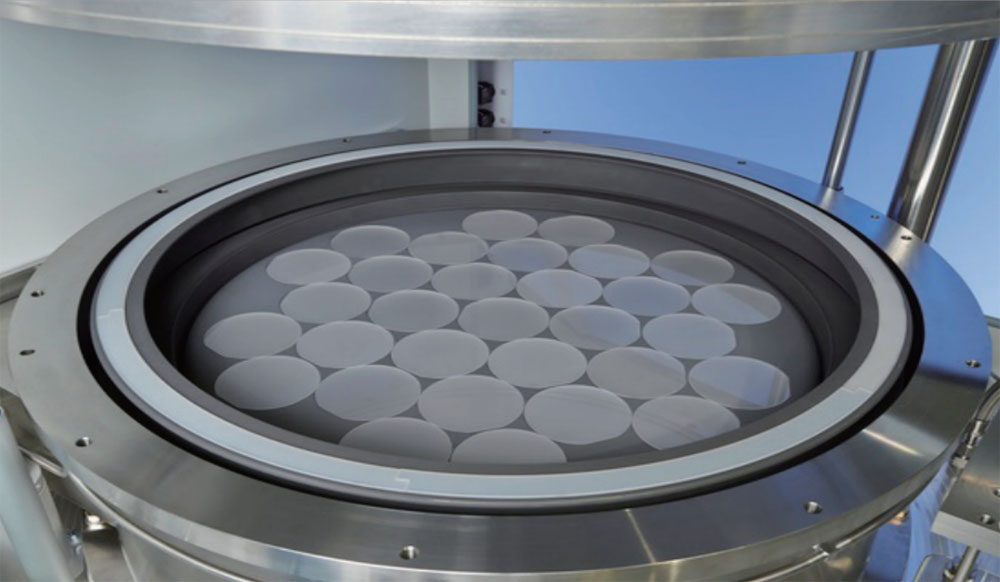

CVD technology plays a crucial role in the application of Momentive TaC coatings. This process involves gas-phase chemical reactions to form solid thin films on substrates. I have observed that CVD is particularly effective for creating uniform coatings, making it ideal for high-precision applications.

Physical Vapor Deposition (PVD)

PVD, on the other hand, is a purely physical process. It vaporizes materials through evaporation or sputtering and condenses them onto substrates to form thin films. This method is widely used for its efficiency and ability to produce durable coatings.

Other Coating Technologies

While CVD and PVD dominate the market, other technologies also contribute to the application of Momentive TaC coatings. These include advanced hybrid techniques that combine the benefits of both CVD and PVD, offering enhanced performance and versatility.

| Technology | Process Description |

|---|---|

| PVD | A purely physical process where materials are vaporized through evaporation or sputtering and then condensed on the substrate to form a thin film. |

| CVD | A technique that involves gas-phase chemical reactions to form solid thin films on the substrate. |

By Region

North America

North America remains a key market for Momentive TaC coatings. The aerospace and automotive industries drive much of the demand here. I have noticed that the region's focus on advanced manufacturing technologies further supports market growth.

Europe

Europe's market growth is fueled by its automotive, medical, and manufacturing sectors. The region's emphasis on sustainability and innovation aligns well with the properties of Momentive TaC coatings. I expect Europe to maintain a strong growth trajectory.

Asia-Pacific

Asia-Pacific dominates the market due to rapid industrialization and its leadership in electronics manufacturing. The region's aerospace and automotive industries also contribute significantly to the demand for these coatings. I believe its high CAGR reflects the immense potential of this market.

Rest of the World

Emerging markets in Latin America and the Middle East present untapped opportunities for Momentive TaC coatings. However, challenges such as limited infrastructure and market penetration strategies need to be addressed to unlock their full potential.

| Region | Major Growth Drivers | CAGR (%) |

|---|---|---|

| North America | Aerospace, Automotive, Oil & Gas | N/A |

| Europe | Automotive, Medical, Manufacturing | 27.85 |

| Asia Pacific | Aerospace, Automotive, Electronics | 29.63 |

Regional Insights

North America

Market Size and Growth Potential

North America remains a significant market for Momentive TaC coatings. The region's market size was valued at USD 1.42 billion in 2022 and is projected to reach USD 2.55 billion by 2030, growing at a CAGR of 7.5%. Between 2024 and 2030, the market is expected to experience an impressive CAGR of 28.74%. This growth reflects the increasing adoption of advanced coatings across industries.

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2022 | 1.42 | N/A |

| 2030 | 2.55 | 7.5 |

| 2024-2030 | N/A | 28.74 |

Key Industries and Applications

The aerospace industry in North America drives much of the demand for these coatings. They protect aircraft components from wear and corrosion, ensuring reliability and safety. The automotive sector also benefits from Momentive TaC coatings, which enhance the durability of car components. Additionally, the oil and gas industry uses these coatings to safeguard drilling equipment from harsh conditions. These industries rely on the unique properties of TaC coatings to improve performance and reduce maintenance costs.

Europe

Technological Advancements Driving Growth

Europe's market growth is fueled by technological advancements that enhance the performance and applicability of Momentive TaC coatings. These innovations are particularly impactful in the automotive, medical, and manufacturing sectors. For example, advanced coating techniques now allow for better protection of components from wear and corrosion. This broadens the range of applications for TaC coatings, making them indispensable in industries that demand high-performance materials.

Focus on Sustainability and Innovation

Sustainability plays a crucial role in the adoption of Momentive TaC coatings in Europe. I have observed a growing demand for eco-friendly solutions in the region. Companies are actively developing sustainable TaC coating technologies to meet this demand. This focus on innovation and environmental responsibility aligns with Europe's broader commitment to sustainability, further driving market growth.

- Sustainability is becoming a priority in the TaC coating market.

- The demand for sustainable solutions is increasing rapidly.

- Companies are investing in eco-friendly TaC coating technologies.

Asia-Pacific

Rapid Industrialization and Infrastructure Development

Asia-Pacific is experiencing the highest growth rate in the Momentive TaC coating market. Rapid industrialization in countries like China and India is a key driver. The region's expanding electronics sector also contributes significantly to this growth. Investments in the automotive and aerospace industries further boost demand for these coatings. I believe this combination of factors positions Asia-Pacific as a dominant player in the global market.

Dominance in Electronics Manufacturing

Asia-Pacific leads the world in electronics manufacturing, which directly impacts the demand for Momentive TaC coatings. These coatings are essential for thermal management systems, thin film deposition, and semiconductor manufacturing. They enhance the thermal and electrical properties of components, making them ideal for high-performance electronics. The region's dominance in this sector ensures a steady demand for TaC coatings.

- Thermal management systems rely on TaC-coated graphite substrates for efficient heat dissipation.

- Thin film deposition processes benefit from the stable surfaces provided by these coatings.

- Semiconductor manufacturing uses TaC coatings to improve thermal and electrical properties.

Rest of the World

Emerging Markets and Untapped Opportunities

I see immense potential for Momentive TaC coatings in emerging markets across the globe. Latin America, in particular, stands out as a region with significant growth opportunities. Economic development and increasing investments in technology and infrastructure are driving demand for advanced materials like TaC coatings. These coatings are becoming essential in industries such as automotive, aerospace, and manufacturing.

Several factors contribute to the untapped opportunities in these regions:

- Latin America: Economic growth and infrastructure development are creating a demand for durable and high-performance materials.

- Middle East and Africa: The oil and gas sector in these regions can benefit from the corrosion resistance of TaC coatings.

- Southeast Asia: Rapid industrialization and the expansion of the electronics industry are fueling demand for advanced coatings.

The global TaC coating market is projected to grow from USD 1.42 billion in 2022 to USD 2.55 billion by 2030, with a CAGR of 7.5% from 2024 to 2030. This growth highlights the increasing adoption of these coatings in emerging markets. I believe these regions represent a golden opportunity for stakeholders to expand their reach and capitalize on the growing demand.

Challenges in Market Penetration

Despite the promising opportunities, penetrating these emerging markets comes with its own set of challenges. I have observed that infrastructure limitations often hinder the adoption of advanced technologies like TaC coatings. Many regions lack the necessary facilities for manufacturing and applying these coatings effectively.

Other challenges include:

- High upfront costs: The initial investment required for TaC coating technology can deter smaller businesses.

- Range anxiety: Limited awareness about the benefits of TaC coatings can slow down market adoption.

Addressing these challenges requires strategic investments in infrastructure and education. Companies must also focus on reducing costs through innovation and economies of scale. By overcoming these barriers, I believe the Momentive TaC coating market can unlock its full potential in these regions.

Competitive Landscape

Major Players in the Momentive TaC Coating Market

Overview of Key Companies

The Momentive TaC coating market features several prominent players. These companies have established themselves as leaders through innovation and strategic growth. I have observed that Momentive Technologies, Tokai Carbon Co., Ltd., Toyo Tanso Co., Ltd., Bay Carbon Inc., and ACME dominate the market. Each company contributes significantly to the industry's development.

| Company Name | Revenue (2020-2025) | Gross Margin (%) | Market Share (%) |

|---|---|---|---|

| Momentive Technologies | $XX million | XX% | XX% |

| Tokai Carbon Co., Ltd. | $XX million | XX% | XX% |

| Toyo Tanso Co., Ltd. | $XX million | XX% | XX% |

| Bay Carbon Inc. | $XX million | XX% | XX% |

| ACME | $XX million | XX% | XX% |

These companies have maintained their competitive edge by focusing on quality, innovation, and customer satisfaction. Their ability to adapt to market demands ensures their continued success.

Market Share and Strategies

I have noticed that market leaders employ diverse strategies to strengthen their positions. Momentive Technologies, for instance, invests heavily in R&D to develop advanced coating solutions. Tokai Carbon Co., Ltd. focuses on expanding its global footprint through acquisitions and partnerships. Toyo Tanso Co., Ltd. emphasizes sustainability, aligning its products with eco-friendly standards. These strategies not only enhance their market share but also set benchmarks for the industry.

Innovations and R&D Investments

New Coating Technologies

Innovation drives the growth of the Momentive TaC coating market. Companies are developing new technologies to meet the evolving needs of industries. For example, advancements in chemical vapor deposition (CVD) and physical vapor deposition (PVD) techniques have improved the performance and durability of coatings. I believe these innovations will continue to shape the market, offering solutions for high-performance applications.

Strategic Partnerships and Collaborations

Strategic partnerships play a crucial role in the market's evolution. I have observed that collaborations between companies enhance R&D efforts, enabling the development of cutting-edge technologies. These partnerships also help optimize supply chains and adapt to changing consumer preferences. As the market recovers from global disruptions, such collaborations will be essential for sustained growth.

Note: Strategic alliances not only foster innovation but also create opportunities for market expansion. Companies that prioritize collaboration are better positioned to address industry challenges and capitalize on emerging trends.

Emerging Trends and Opportunities

Innovations in TaC Coating Materials

I have observed that the demand for high-performance materials is reshaping the TaC coating market. Industries like aerospace and semiconductor manufacturing increasingly require durable, high-temperature-resistant materials. This trend has led to a surge in the use of TaC-coated susceptors. Technological advancements in coating processes, particularly in CVD and PVD technologies, are also enhancing the efficiency and reliability of these coatings. These innovations make them more appealing for industrial applications.

The semiconductor industry, especially in SiC-based technologies, is another major driver. As this sector grows, the need for high-quality substrates like TaC-coated susceptors expands. Emerging markets are also opening new doors for these coatings, with applications in energy production and electronics gaining traction. Ongoing research and development in advanced coatings promise further breakthroughs, ensuring the market remains dynamic and full of opportunities.

| Trend/Opportunity | Description |

|---|---|

| Growing Demand for High-Performance Materials | The need for durable, high-temperature-resistant materials in industries like semiconductor manufacturing and aerospace is driving the demand for TaC-coated susceptors. |

| Technological Advancements in Coating Processes | Innovations in CVD and PVD technologies are increasing the efficiency and reliability of TaC-coated susceptors, making them more attractive for industrial applications. |

| Rise in Semiconductor Industry Demand | As the semiconductor industry grows, particularly in SiC-based technologies, the need for high-quality substrates like TaC-coated susceptors is expanding. |

| Expanding Applications in Emerging Markets | As industries in developing economies increase their demand for advanced materials, the opportunity for TaC-coated susceptors to enter new markets, such as energy production and electronics, is growing. |

| Research and Development in Advanced Coatings | Ongoing R&D into improving TaC coating processes and exploring new materials can lead to innovations and increased market opportunities. |

| Rising Demand for SiC in Semiconductor Manufacturing | As SiC technology becomes more prevalent in power electronics, there is significant potential for the growth of TaC-coated susceptors in this niche application. |

Adoption in Emerging Industries

I see a growing interest in TaC coatings across emerging industries. Sectors like renewable energy, advanced manufacturing, and medical devices are beginning to adopt these coatings for their unique properties. For instance, in renewable energy, TaC coatings improve the durability of components exposed to extreme conditions. In medical devices, they enhance the wear resistance of surgical tools and implants, ensuring longer lifespans and better performance.

The electronics industry, particularly in Asia-Pacific, continues to dominate the adoption of these coatings. However, I believe industries in developing economies are also recognizing their value. As these markets expand, the adoption of TaC coatings will likely accelerate, creating new opportunities for stakeholders.

Sustainability and Eco-Friendly Solutions

Sustainability is becoming a cornerstone of the TaC coating market. I have noticed a shift toward eco-friendly and sustainable solutions in the industry. Companies are developing greener coating processes and recycling materials to reduce environmental impact. These efforts not only align with global sustainability goals but also improve brand reputation and customer loyalty.

- Development of eco-friendly coating processes.

- Recycling of coating materials to minimize waste.

- Reducing the environmental impact of coating operations.

Implementing sustainable practices involves using renewable energy, optimizing transportation, and adopting circular economy concepts. These initiatives offer long-term benefits, including regulatory compliance and enhanced market competitiveness. I believe the momentive tac coating market is well-positioned to lead this sustainability movement, setting an example for other industries.

Challenges and Market Risks

The Momentive TaC coating market, despite its promising growth, faces several challenges that could hinder its trajectory. I have observed that product differentiation remains a critical issue. Many companies struggle to stand out in a competitive landscape where similar offerings dominate. This lack of uniqueness can dilute brand value and make it harder to attract customers.

Cost reduction is another pressing concern. Manufacturing TaC coatings involves advanced technologies like chemical vapor deposition (CVD) and physical vapor deposition (PVD), which require significant investment. High production costs often translate to higher prices for end-users, limiting adoption in cost-sensitive markets. Companies must find innovative ways to streamline processes and reduce expenses without compromising quality.

Supply chain optimization also poses a challenge. The global nature of the TaC coating market means that raw materials and components often come from multiple regions. Disruptions in the supply chain, whether due to geopolitical tensions or logistical issues, can delay production and increase costs. I believe businesses need to invest in robust supply chain management systems to mitigate these risks.

Infrastructure limitations further complicate market expansion, particularly in emerging economies. Many regions lack the facilities needed to manufacture and apply advanced coatings effectively. This gap restricts the market's ability to penetrate new territories and capitalize on untapped opportunities.

High upfront costs represent another significant risk. The initial investment required for TaC coating technology can deter smaller businesses from entering the market. This barrier limits competition and innovation, which are essential for long-term growth.

Addressing these challenges requires a strategic approach. Companies must focus on innovation, cost efficiency, and infrastructure development to overcome these hurdles and unlock the full potential of the Momentive TaC coating market.

The Momentive TaC coating market presents immense growth potential, driven by its adoption across industries like aerospace, automotive, and medical. These sectors rely on TaC coatings for their durability, high-temperature resistance, and corrosion protection. Technological advancements continue to expand their applications, while the push for sustainability fosters the development of eco-friendly solutions.

Staying informed about market trends is crucial for stakeholders. Opportunities abound in emerging economies, technological innovations, and strategic partnerships. By investing in research and optimizing supply chains, businesses can position themselves for success. I encourage stakeholders to act on these insights and capitalize on the evolving landscape of the momentive tac coating market.

FAQ

What makes Momentive TaC coatings unique compared to other coatings?

Momentive TaC coatings stand out due to their exceptional durability, high melting point, and superior corrosion resistance. These properties make them ideal for high-temperature and high-wear applications. I’ve seen industries like aerospace and electronics rely on these coatings to enhance the performance and lifespan of their components.

Which industries benefit the most from Momentive TaC coatings?

Industries such as aerospace, automotive, and electronics benefit the most. These coatings protect components from wear and corrosion, ensuring reliability in extreme conditions. For example, I’ve noticed their widespread use in turbine blades, semiconductor manufacturing, and high-performance vehicle parts.

How do advancements in coating technologies impact the market?

Advancements in technologies like CVD and PVD improve the efficiency and precision of Momentive TaC coatings. These innovations allow industries to meet evolving demands for high-performance materials. I believe this continuous improvement drives market growth and expands the range of applications.

Are Momentive TaC coatings environmentally friendly?

Yes, companies are increasingly focusing on sustainable practices. I’ve observed efforts to develop eco-friendly coating processes and recycle materials. These initiatives align with global sustainability goals, making Momentive TaC coatings a responsible choice for industries prioritizing environmental impact.

What challenges do companies face in adopting Momentive TaC coatings?

High upfront costs and infrastructure limitations pose challenges. I’ve seen smaller businesses struggle with the investment required for advanced coating technologies. Additionally, supply chain disruptions can hinder adoption. Addressing these issues requires strategic planning and innovation.

Contact Us To Get Better Information

By:semicera

Address : No. 1958 Jiangnan Road, Ningbo High tech Zone, Zhejiang Province, 315201, China

E-mail : sales01@semi-cera.com

E-mail : sales05@semi-cera.com

Tel : 86-0574-8650 3783

Phone : 86-13373889683

Skype : xianeryeah@outlook.com

Whatsapp : 86-13373889683

Xing:https://www.xing.com/discover/your-posts

Pinterest:https://www.pinterest.com/Semicera/

Facebook:https://www.facebook.com/profile.php?id=61575124466678

Youtube:https://www.youtube.com/@Semicera