Silicon carbide coated susceptors represent a breakthrough in material science, offering unmatched performance in high-temperature environments. In 2025, manufacturers employ cutting-edge techniques to produce these advanced components. The process begins with selecting premium materials, followed by precision shaping and machining. Surface preparation ensures optimal adhesion for the silicon carbide coating, applied using state-of-the-art methods like chemical vapor deposition (CVD).

The advancements in manufacturing techniques for silicon carbide coated susceptors in 2025 focus on enhanced durability, thermal performance, and the integration of smart technologies for improved efficiency. Silicon carbide (SiC) coatings have revolutionized susceptor technology by significantly enhancing durability. These coatings provide exceptional resistance to thermal degradation and chemical corrosion, making them ideal for high-temperature semiconductor processes.

Smicera Semiconductor has emerged as a leader in this field, leveraging its expertise in SIC coating and surface treatment. With a strong R&D team and ISO 9001:2015 certification, the company delivers innovative solutions for industries like photovoltaics, semiconductors, and renewable energy. Its SiC coated graphite susceptors exemplify the fusion of durability, thermal stability, and precision engineering, meeting the demands of modern technologies. The company's commitment to producing high-quality SiC coated susceptors ensures that they remain at the forefront of advanced material technology.

Key Takeaways

- Silicon carbide coated susceptors work well in very hot places. They are important for industries like semiconductors and aerospace.

- Making them includes using good materials, shaping carefully, and using special coatings like chemical vapor deposition (CVD).

- These coatings help with heat transfer, resist chemicals, and stay strong, making them last longer.

- They keep materials clean during manufacturing by lowering contamination risks.

- New technologies, like PECVD and ALD, bring better coating methods for even surfaces and better results.

- They help the environment by lasting longer and using less energy.

- Smicera Semiconductor is a leader, using research and certified quality to make great products.

- Using these susceptors can save money and make work faster and better.

Understanding Silicon Carbide Coated Susceptors

What Are Silicon Carbide Coated Susceptors?

Silicon carbide coated susceptors are advanced components designed to withstand extreme conditions in high-performance industrial processes. These susceptors consist of a base material, often graphite, coated with a layer of silicon carbide (SiC). The SiC coating enhances the base material's properties, making it more durable and resistant to harsh environments.

Silicon carbide (SiC) coatings possess unique properties that make them indispensable for protecting graphite susceptors in harsh environments. These properties enhance the material’s ability to resist corrosion, maintain structural integrity, and perform reliably under extreme conditions. The non-reactive nature of SiC coatings prevents it from interacting with aggressive chemicals such as acids, alkalis, and salts. Research highlights that SiC coatings effectively resist chemical reactions, making them ideal for applications in semiconductor manufacturing and chemical processing industries. Their ability to maintain purity reduces contamination risks, a crucial factor in sensitive industrial processes.

The coating process, such as chemical vapor deposition (CVD), ensures a uniform and high-quality SiC layer. This layer provides exceptional thermal conductivity, chemical resistance, and mechanical strength. These characteristics make silicon carbide coated susceptors essential for industries requiring precision and reliability.

Why Are They Important in High-Performance Applications?

Silicon carbide coated susceptors play a critical role in industries that demand materials capable of withstanding extreme temperatures, chemical exposure, and mechanical stress. Their unique properties make them indispensable in several high-performance applications.

SiC coatings excel in thermal conductivity and stability, enabling them to withstand extreme temperatures without compromising their structural integrity. This property is particularly important in high-temperature environments, where materials often face thermal stress and degradation. Studies emphasize that SiC coatings provide superior thermal stability, allowing them to endure rapid temperature changes and resist thermal shock.

Industries such as semiconductor manufacturing, aerospace, and renewable energy rely heavily on these susceptors. In semiconductor manufacturing, they are essential for processes like chemical vapor deposition (CVD) and epitaxy, where precise thermal control and chemical resistance are crucial. Aerospace applications benefit from their ability to maintain structural integrity under extreme conditions, while renewable energy systems use them for their durability and efficiency.

- Photovoltaic cell production: Enhances solar panel efficiency through precise thermal processing.

- Semiconductor manufacturing: Essential for chemical vapor deposition (CVD) and epitaxy processes.

- Aerospace: Supports advanced manufacturing processes for cutting-edge materials.

- Renewable energy: Adapts to the demands of emerging technologies.

Smicera Semiconductor has established itself as a leader in producing silicon carbide coated susceptors. The company combines advanced R&D capabilities with ISO 9001:2015-certified quality management systems to deliver innovative solutions. Its products, including SiC coated graphite susceptors, are widely used in photovoltaics, semiconductors, and other high-performance industries. By focusing on durability, thermal stability, and precision engineering, Smicera ensures its products meet the demands of modern technologies.

The hardness and mechanical strength of SiC coatings play a vital role in enhancing the durability of graphite susceptors. SiC ranks high on the Mohs scale of hardness, making it resistant to wear and abrasion. According to industry reports, SiC coatings improve the resilience of graphite susceptors, enabling them to withstand mechanical impacts and maintain their structural integrity.

These properties and applications highlight the importance of silicon carbide coated susceptors in driving innovation and efficiency across various industries.

Step-by-Step Manufacturing Process of Silicon Carbide Coated Susceptors

Material Selection

Choosing the Base Material

The selection of the base material is a critical step in manufacturing silicon carbide coated susceptors. Manufacturers prioritize materials that exhibit high thermal conductivity, stability, and corrosion resistance. These properties ensure the base material can endure the extreme conditions of high-performance applications. Additionally, surface flatness and bonding strength are essential for achieving a uniform coating and preventing thermal cycle-induced cracking. The table below outlines the key criteria for selecting the base material:

| Criteria | Description |

|---|---|

| Thermal Conductivity | Essential for fast and uniform heat distribution during chip growth. |

| Stability | The base material must maintain its properties under high-temperature conditions. |

| Corrosion Resistance | The material should withstand corrosive environments without degrading. |

| Surface Flatness | High surface flatness is required for applications like single crystal growth. |

| Bonding Strength | Strong bonds between the base and coating are necessary to prevent cracking during thermal cycles. |

| High Melting Point | The coating must resist oxidation and corrosion at elevated temperatures. |

Importance of High-Quality Silicon Carbide

High-quality silicon carbide plays a pivotal role in enhancing the performance of susceptors. Recent advancements in SiC coatings have significantly improved their durability and thermal efficiency. These coatings protect against oxidation and erosion, ensuring long-term reliability in semiconductor manufacturing. They also optimize heat distribution and resist chemical degradation, reducing contamination risks. These features extend the operational lifespan of susceptors, making them indispensable in high-performance industries.

Shaping and Machining

Techniques for Shaping the Base Material

Shaping the base material requires precision to meet the exact specifications of silicon carbide coated susceptors. Abrasive machining is a preferred technique as it minimizes micro-cracks and subsurface damage. This method ensures the base material maintains its structural integrity during high-temperature operations. Microwave annealing further enhances the material by improving recrystallization and activating dopants, making it suitable for demanding applications.

Precision Machining for Complex Designs

Precision machining has evolved to meet the intricate design requirements of modern susceptors. Techniques like mechanical polishing with diamond abrasives reduce surface roughness, ensuring a smooth finish. Chemical-mechanical polishing (CMP) minimizes micro-cracks and subsurface damage, providing uniformity across the surface. Finishing polish controls protrusion heights, preventing defects during semiconductor manufacturing. These advancements enable manufacturers to produce susceptors with complex geometries and superior performance.

Surface Preparation

Cleaning and Pre-Treatment

Surface preparation is essential for achieving a strong bond between the base material and the silicon carbide coating. Cleaning methods such as chemical cleaning, ultrasonic cleaning, and plasma cleaning remove contaminants and ensure a pristine surface. The table below highlights the steps involved in pre-treatment:

| Step | Description | Conditions |

|---|---|---|

| 1 | Formation of initial layer | Pressure: 3.5 Torr, Temperature: 400°C, Power: 3000 W |

| 2 | Formation of CF coating | Temperature: 350°C or more, Cleaning gas: NF3 or C2F6, Noble gas ratio: 60%-80% |

Ensuring Adhesion for the Coating Process

Proper surface preparation ensures the silicon carbide coating adheres uniformly to the base material. Techniques like plasma cleaning enhance the surface's bonding properties, reducing the risk of delamination during thermal cycles. This step is crucial for maintaining the coating's durability and performance in extreme environments.

Coating Application

Chemical Vapor Deposition (CVD) Process

The chemical vapor deposition (CVD) process is a widely used method for applying silicon carbide coatings. This technique ensures a uniform and high-quality layer, enhancing the performance of silicon carbide coated susceptors. The process involves several key steps:

- Introduce gaseous raw materials, such as silicon and carbon precursors, into a reaction chamber.

- React the gases at high temperatures, typically ranging from 1000°C to 2000°C.

- Deposit silicon carbide onto the substrate, which could be a silicon wafer or another base material.

This process creates a dense and durable coating that adheres strongly to the substrate. The high-temperature reaction ensures the formation of a pure silicon carbide layer, which provides excellent thermal conductivity and chemical resistance. Manufacturers rely on CVD for its precision and ability to produce coatings with consistent thickness and quality.

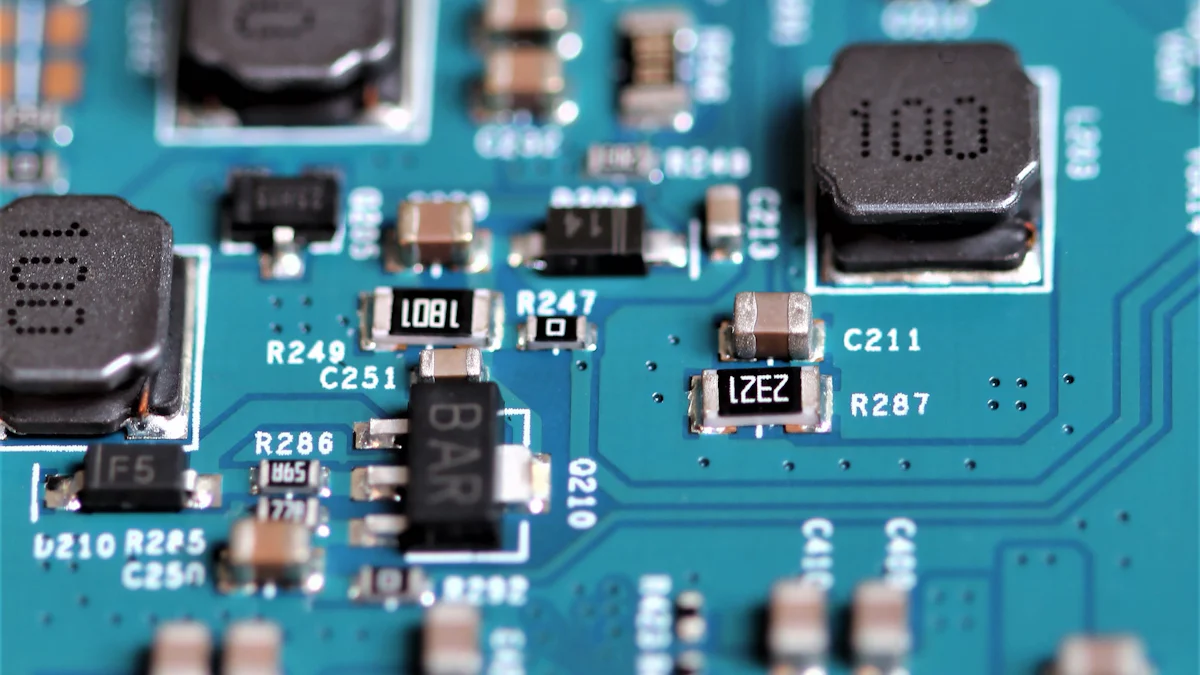

Alternative Coating Techniques in 2025

In 2025, advancements in technology have introduced alternative methods for applying silicon carbide coatings. Techniques such as plasma-enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD) offer enhanced control over coating thickness and composition. PECVD uses plasma to activate chemical reactions at lower temperatures, making it suitable for temperature-sensitive substrates. ALD, on the other hand, allows for atomic-level precision, ensuring uniform coatings even on complex geometries.

These innovative methods complement traditional CVD by addressing specific application needs. For instance, PECVD is ideal for substrates requiring lower thermal exposure, while ALD excels in creating ultra-thin, conformal coatings. Together, these techniques expand the possibilities for manufacturing high-performance silicon carbide coated susceptors.

Quality Control and Testing

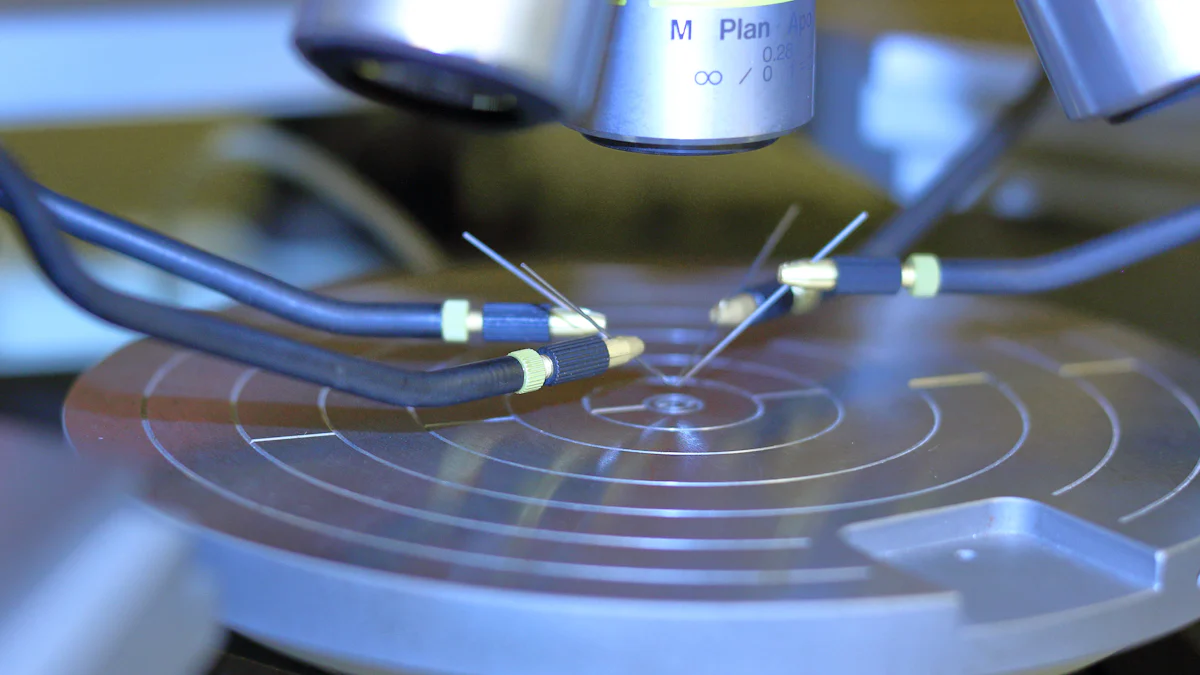

Inspection for Coating Uniformity

Quality control plays a vital role in ensuring the reliability of silicon carbide coated susceptors. Inspection for coating uniformity involves advanced imaging techniques, such as scanning electron microscopy (SEM) and optical profilometry. These methods detect any inconsistencies in the coating's thickness or surface finish. Uniform coatings are essential for maintaining thermal and mechanical performance during high-temperature operations.

Automated inspection systems have become standard in 2025, enabling manufacturers to identify defects with greater accuracy and efficiency. These systems analyze large batches of susceptors, ensuring consistent quality across production lines. By prioritizing uniformity, manufacturers enhance the durability and performance of their products.

Thermal and Mechanical Testing

Thermal and mechanical testing validates the performance of silicon carbide coated susceptors under extreme conditions. Key tests include:

- Thermal Conductivity Testing: Measures the coating's ability to distribute heat evenly.

- Thermal Shock Resistance: Assesses the coating's endurance against rapid temperature changes.

- Mechanical Strength Testing: Evaluates resistance to physical stress, including tensile and compressive forces.

- Doping Uniformity Assessment: Ensures consistent doping concentrations during semiconductor growth processes.

- Thermal Expansion Compatibility: Verifies that the coating's thermal expansion matches the substrate, preventing cracks or delamination.

These tests ensure that silicon carbide coated susceptors meet the rigorous demands of industries like semiconductors and aerospace. Smicera Semiconductor employs state-of-the-art testing facilities to maintain the highest standards of quality. Their commitment to excellence has earned them recognition as a leader in advanced material technology.

Key Properties of Silicon Carbide Coated Susceptors

Thermal Conductivity and Heat Resistance

Silicon carbide coated susceptors excel in thermal conductivity and heat resistance, making them indispensable in high-temperature applications. The silicon carbide coating enhances the thermal conductivity of the graphite substrate, ensuring rapid and uniform heating. This property is critical for semiconductor manufacturing, where precise temperature control directly impacts the quality of the final product.

- The uniform heat distribution minimizes temperature inconsistencies, leading to precise results during processes like epitaxy.

- The enhanced thermal conductivity reduces energy waste, contributing to higher operational efficiency.

- The coating withstands thermal shock and cyclic loads, ensuring long-term durability in demanding environments.

These properties allow silicon carbide coated susceptors to maintain their structural integrity even under extreme thermal conditions. Smicera Semiconductor’s advanced R&D capabilities ensure that their susceptors meet the highest standards of thermal performance, supporting industries like photovoltaics and semiconductors.

Chemical and Corrosion Resistance

Silicon carbide coatings provide exceptional resistance to chemical corrosion, making them ideal for harsh industrial environments. The chemical inertness of silicon carbide prevents reactions with corrosive agents such as acids, alkalis, and salts. This non-reactive nature minimizes contamination risks, which is essential in sensitive processes like semiconductor manufacturing.

- The coatings maintain the structural integrity of the underlying graphite, ensuring consistent performance over time.

- Their resistance to chemical degradation protects wafers during epitaxy, preserving the purity of the materials.

Smicera Semiconductor’s silicon carbide coated susceptors exemplify these qualities. Their products are designed to endure aggressive chemical environments while maintaining high performance. This durability ensures that industries relying on these susceptors experience fewer interruptions and lower maintenance costs.

Mechanical Strength and Durability

The mechanical strength of silicon carbide coatings significantly enhances the durability of graphite susceptors. Silicon carbide ranks high on the Mohs scale of hardness, making it resistant to wear and abrasion. This property is particularly important in applications involving mechanical stress or abrasive conditions.

The silicon carbide layer provides mechanical stability, enabling susceptors to endure extreme conditions without compromising functionality. This durability reduces the frequency of replacements, minimizing downtime and boosting productivity. Smicera Semiconductor’s commitment to quality ensures that their susceptors deliver consistent performance, even in the most demanding applications.

These key properties—thermal conductivity, chemical resistance, and mechanical strength—make silicon carbide coated susceptors essential for modern industries. Smicera Semiconductor’s expertise in advanced materials and surface treatments positions them as a leader in this field, delivering solutions that meet the evolving needs of high-performance applications.

Longevity and Cost-Effectiveness

Silicon carbide coated susceptors demonstrate exceptional longevity, making them a cost-effective choice for industries requiring high-performance materials. The silicon carbide layer acts as a robust shield, protecting the base material from wear, corrosion, and thermal stress. This protective barrier significantly extends the lifespan of the susceptor, even in the most demanding environments. Industries benefit from this durability, as it reduces the frequency of replacements and minimizes operational disruptions.

Enhanced thermal efficiency further contributes to cost-effectiveness. The silicon carbide coating improves heat distribution, ensuring processes consume less energy. This reduction in energy usage lowers operational costs, making these susceptors an economical solution for industries like semiconductor manufacturing and photovoltaics. By optimizing thermal performance, manufacturers achieve higher productivity while maintaining lower energy expenses.

The durability of silicon carbide coated susceptors also reduces maintenance costs. Frequent replacements and repairs are unnecessary due to the material's ability to withstand harsh conditions. This reliability ensures uninterrupted operations, saving both time and resources. For example, in semiconductor manufacturing, where precision and consistency are critical, the long-lasting nature of these susceptors ensures stable performance over extended periods.

Smicera Semiconductor exemplifies the balance between longevity and cost-effectiveness in its products. The company’s silicon carbide coated susceptors are designed to endure extreme conditions while maintaining high performance. By leveraging advanced R&D capabilities and ISO 9001:2015-certified quality management systems, Smicera delivers solutions that meet the rigorous demands of modern industries. Their products reduce downtime and operational costs, providing customers with a reliable and economical option for high-performance applications.

Applications of Silicon Carbide Coated Susceptors in 2025

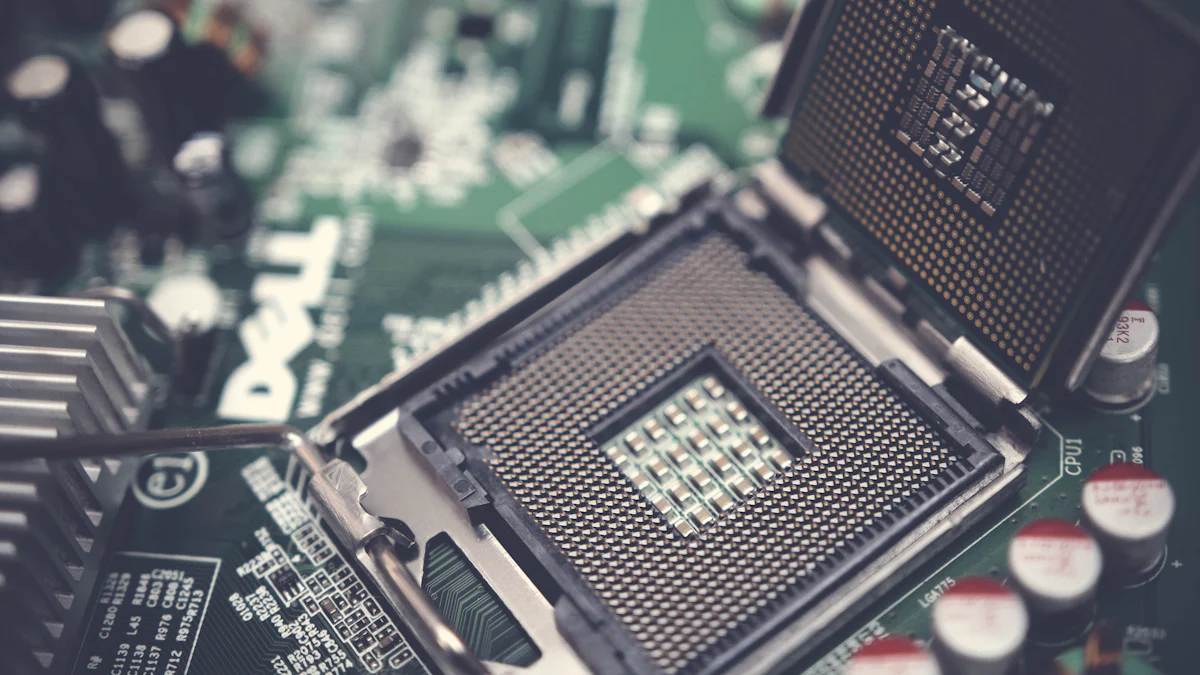

Semiconductor Manufacturing

Silicon carbide coated susceptors play a vital role in semiconductor manufacturing. These components enhance the performance and durability of graphite substrates in high-temperature processes. Their silicon carbide coating provides superior thermal conductivity, chemical resistance, and mechanical stability. These attributes make them essential for critical processes like chemical vapor deposition (CVD) and epitaxy.

- The coating prevents contamination by resisting chemical reactions and particle generation.

- It creates a clean processing environment, reducing the risk of impurities affecting wafers.

- The coating ensures structural integrity under high temperatures and corrosive conditions.

These features improve the reliability and quality of semiconductor devices. Smicera Semiconductor’s silicon carbide coated susceptors exemplify these qualities. Their products meet the rigorous demands of semiconductor manufacturing, ensuring consistent performance and high-quality results.

Aerospace and Defense

In aerospace and defense, silicon carbide coated susceptors provide exceptional performance under extreme conditions. Their ability to endure high temperatures and corrosive environments makes them indispensable in these industries.

- The coating offers thermal stability and chemical resistance, ensuring consistent performance.

- Mechanical durability reduces equipment downtime and replacement frequency.

These properties are crucial for high-performance applications, such as advanced material processing and thermal management systems. Smicera Semiconductor’s expertise in producing durable and reliable susceptors supports the demanding needs of aerospace and defense operations. Their products ensure efficiency and longevity, even in the harshest environments.

Renewable Energy Systems

Renewable energy systems benefit greatly from silicon carbide coated susceptors. Their durability and thermal efficiency make them ideal for applications like solar panel production.

- The coating extends the lifespan of susceptors, reducing waste and replacement frequency.

- Enhanced thermal efficiency improves energy usage, which is critical for renewable energy processes.

- Chemical resistance allows them to withstand harsh industrial environments.

These advantages contribute to the efficiency and sustainability of renewable energy systems. Smicera Semiconductor’s silicon carbide coated susceptors support the production of photovoltaic cells and other renewable energy technologies. Their products help industries achieve higher productivity while maintaining environmental responsibility.

Emerging Technologies and Future Trends

Emerging technologies in 2025 are reshaping industries and driving the demand for advanced materials like silicon carbide coated susceptors. These innovations require materials that can withstand extreme conditions while delivering superior performance. Silicon carbide coated susceptors meet these demands, making them indispensable in cutting-edge applications.

Advancements in Semiconductor Manufacturing

The semiconductor industry continues to evolve with the development of metal-organic chemical vapor deposition (MOCVD) solutions. These processes demand materials with exceptional thermal stability and chemical resistance. Silicon carbide coated susceptors enhance process efficiency and yield, making them a preferred choice for manufacturers. Their ability to maintain structural integrity under high temperatures ensures consistent performance during critical operations.Wide-Bandgap Semiconductors

The adoption of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is transforming power electronics, RF devices, and optoelectronics. These materials offer higher efficiency and reliability compared to traditional semiconductors. Silicon carbide coated susceptors play a vital role in the production of these advanced devices, supporting the growing demand for high-performance components.Energy Efficiency and Sustainability

The global focus on energy efficiency has increased the demand for SiC-based semiconductors. These semiconductors enable energy-efficient technologies, reducing power consumption in various applications. Silicon carbide coated susceptors contribute to this trend by ensuring precise thermal control and minimizing energy waste during manufacturing processes.Emerging Applications

Applications such as electric vehicles (EVs), renewable energy systems, and 5G wireless communications rely on high-performance semiconductor devices. These devices require materials with enhanced power handling capabilities and reliability. Silicon carbide coated susceptors provide the durability and thermal efficiency needed to meet these requirements, supporting the rapid growth of these industries.Government Initiatives

Governments worldwide are promoting the adoption of advanced semiconductor technologies through various initiatives. These efforts stimulate market growth and encourage the development of innovative materials like silicon carbide coated susceptors. By supporting these initiatives, manufacturers can address the increasing demand for high-quality components.

Smicera Semiconductor plays a pivotal role in meeting the needs of these emerging technologies. The company’s expertise in silicon carbide coatings and surface treatments ensures that its products deliver unmatched performance and reliability. With a strong R&D team and ISO 9001:2015-certified quality management systems, Smicera provides innovative solutions for industries like semiconductors, renewable energy, and electric vehicles. Its silicon carbide coated susceptors exemplify the fusion of advanced engineering and practical application, making them essential for the technologies of tomorrow.

The future of silicon carbide coated susceptors lies in their ability to adapt to the demands of emerging technologies. As industries continue to innovate, these advanced materials will remain at the forefront, driving progress and efficiency across various sectors.

Advancements in Manufacturing Techniques for Silicon Carbide Coated Susceptors

Innovations in Coating Technology

Recent innovations in coating technology have significantly improved the efficiency and performance of silicon carbide coated susceptors. Enhanced thermal conductivity now ensures even heat distribution during high-temperature processes. This improvement reduces energy waste and shortens processing times, making manufacturing more efficient. Increased durability allows susceptors to withstand extreme conditions without degradation, minimizing the need for frequent replacements. These advancements lower operational costs and improve reliability.

Chemical vapor deposition (CVD) remains a cornerstone of coating technology. It ensures uniform heating and exceptional thermal conductivity, which are critical for high-precision applications like semiconductor manufacturing. The chemical resistance of silicon carbide coatings protects susceptors from corrosive environments, ensuring long-term stability and preventing contamination. These features make CVD SiC coatings indispensable for industries requiring consistent performance under harsh conditions.

Emerging techniques, such as plasma-enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD), offer additional benefits. PECVD operates at lower temperatures, making it suitable for sensitive substrates. ALD provides atomic-level precision, ensuring uniform coatings even on complex geometries. Together, these technologies expand the possibilities for manufacturing high-performance susceptors.

Automation and Precision in 2025

Automation has revolutionized the manufacturing of silicon carbide coated susceptors in 2025. Automated systems now manage wafer placement and retrieval with unparalleled precision, minimizing human error. Smart susceptor systems equipped with sensors monitor critical parameters in real time, ensuring optimal processing conditions. These systems use artificial intelligence (AI) to fine-tune heat transfer and gas dynamics, improving wafer quality and reducing operational costs.

CVD SiC coatings benefit from these advancements by achieving superior thermal stability and uniform heating. This uniformity enhances heat distribution, reducing energy waste and processing times. AI-driven optimization further refines production cycles, ensuring consistent results across batches. These improvements have led to higher yields in semiconductor fabrication, meeting the growing demand for high-quality components.

Automation also enhances safety and efficiency. By reducing manual intervention, automated systems lower the risk of errors and accidents. They streamline production processes, enabling manufacturers to scale operations without compromising quality. Smicera Semiconductor exemplifies this approach by integrating advanced automation into its manufacturing processes. The company’s commitment to precision and innovation ensures that its silicon carbide coated susceptors meet the highest industry standards.

Sustainability and Eco-Friendly Practices

Sustainability has become a key focus in the production of silicon carbide coated susceptors. Advanced materials and coatings now improve durability and performance, reducing waste from frequent replacements. Energy-efficient designs contribute to lowering the carbon footprint of manufacturing processes. These innovations align with global sustainability efforts in the semiconductor industry.

The extended lifespan of susceptors minimizes waste, while enhanced thermal efficiency reduces energy consumption. These improvements support greener manufacturing goals by lowering environmental impact. For example, SiC-coated susceptors optimize thermal transfer, minimizing heat loss and conserving energy. This efficiency benefits industries like photovoltaics and semiconductors, where energy-intensive processes are common.

Smicera Semiconductor has embraced sustainable practices by prioritizing resource efficiency and environmental responsibility. The company’s silicon carbide coated susceptors exemplify this commitment. By extending product lifespans and reducing energy usage, Smicera supports the transition to more sustainable industrial practices. These efforts not only benefit the environment but also provide cost savings for customers, making sustainability a win-win solution.

The manufacturing process of silicon carbide coated susceptors in 2025 showcases a blend of precision and innovation. From selecting high-quality materials to applying advanced coatings like chemical vapor deposition, each step ensures superior performance. These susceptors excel in thermal conductivity, chemical resistance, and mechanical durability, making them indispensable in industries such as semiconductors, aerospace, and renewable energy.

Future trends promise exciting advancements. Key developments include enhanced thermal performance, wider adoption in CVD applications, and innovative packaging solutions for electronics. Sustainability remains a priority, with manufacturers focusing on eco-friendly practices and reducing waste. Emerging technologies, such as wide-bandgap semiconductors and energy-efficient systems, will further drive demand for these advanced materials.

Silicon carbide coated susceptors continue to shape modern industries by improving efficiency and sustainability. Their role in advancing technology highlights their importance in meeting the challenges of tomorrow.

FAQ

What is the primary purpose of silicon carbide coated susceptors?

Silicon carbide coated susceptors enhance the performance of base materials like graphite. They provide superior thermal conductivity, chemical resistance, and mechanical strength. These properties make them essential for high-temperature and high-precision industrial processes, such as semiconductor manufacturing and photovoltaic cell production.

How does the chemical vapor deposition (CVD) process work?

The CVD process involves introducing silicon and carbon precursors into a reaction chamber. High temperatures cause these gases to react and form a silicon carbide layer on the substrate. This method ensures a uniform, durable coating with excellent thermal and chemical properties.

Why is silicon carbide preferred for coating susceptors?

Silicon carbide offers unmatched thermal conductivity, chemical resistance, and mechanical durability. Its non-reactive nature prevents contamination in sensitive processes. These qualities make it ideal for industries requiring materials that perform reliably under extreme conditions, such as semiconductors and aerospace.

What industries benefit most from silicon carbide coated susceptors?

Industries like semiconductors, aerospace, renewable energy, and photovoltaics benefit significantly. These susceptors improve efficiency, durability, and precision in processes like chemical vapor deposition, epitaxy, and solar panel production. Their ability to withstand harsh environments makes them indispensable in these fields.

How do silicon carbide coated susceptors contribute to sustainability?

Silicon carbide coated susceptors reduce waste by extending the lifespan of base materials. Their enhanced thermal efficiency lowers energy consumption during manufacturing. These features align with global sustainability goals, making them an eco-friendly choice for industries like photovoltaics and semiconductors.

What advancements in 2025 improve susceptor manufacturing?

Automation and AI-driven systems optimize production by ensuring precision and reducing errors. Emerging coating techniques like PECVD and ALD enhance coating uniformity and performance. These advancements improve efficiency, reduce costs, and meet the growing demand for high-quality susceptors.

How does Smicera Semiconductor ensure product quality?

Smicera Semiconductor employs ISO 9001:2015-certified quality management systems. Advanced R&D capabilities and state-of-the-art testing facilities ensure consistent quality. Their silicon carbide coated susceptors meet the rigorous demands of industries like semiconductors, photovoltaics, and aerospace.

Are silicon carbide coated susceptors cost-effective?

Yes, their durability and thermal efficiency reduce replacement frequency and energy consumption. These features lower operational costs and improve productivity. Smicera Semiconductor’s products exemplify cost-effectiveness by delivering long-lasting performance and reliability in high-performance applications