Purity levels in high-purity silicon carbide refer to the concentration of the desired material relative to impurities. These levels play a critical role in determining the material's suitability for advanced applications. Even trace impurities can alter its electrical, thermal, and mechanical properties, leading to performance degradation. Industries demand high-purity silicon carbide to ensure consistent reliability in high-performance environments. Maintaining purity requires stringent control during production and precise measurement techniques. This focus on purity guarantees the material meets the rigorous standards necessary for cutting-edge technologies.

Key Takeaways

- Purity in silicon carbide is key for its performance. Higher purity improves electrical, thermal, and mechanical properties.

- Impurities include metals like iron and aluminum. Non-metals like oxygen and nitrogen are also common. Removing these impurities keeps the material high-quality.

- High-purity silicon carbide is used in semiconductors and aerospace. It reduces defects and works well under high stress.

- Tools like mass spectrometry check purity levels accurately. These tools help meet industry requirements.

- Manufacturers use good raw materials to keep purity consistent. Strict quality checks during production are also important.

What Are Purity Levels in High-Purity Silicon Carbide?

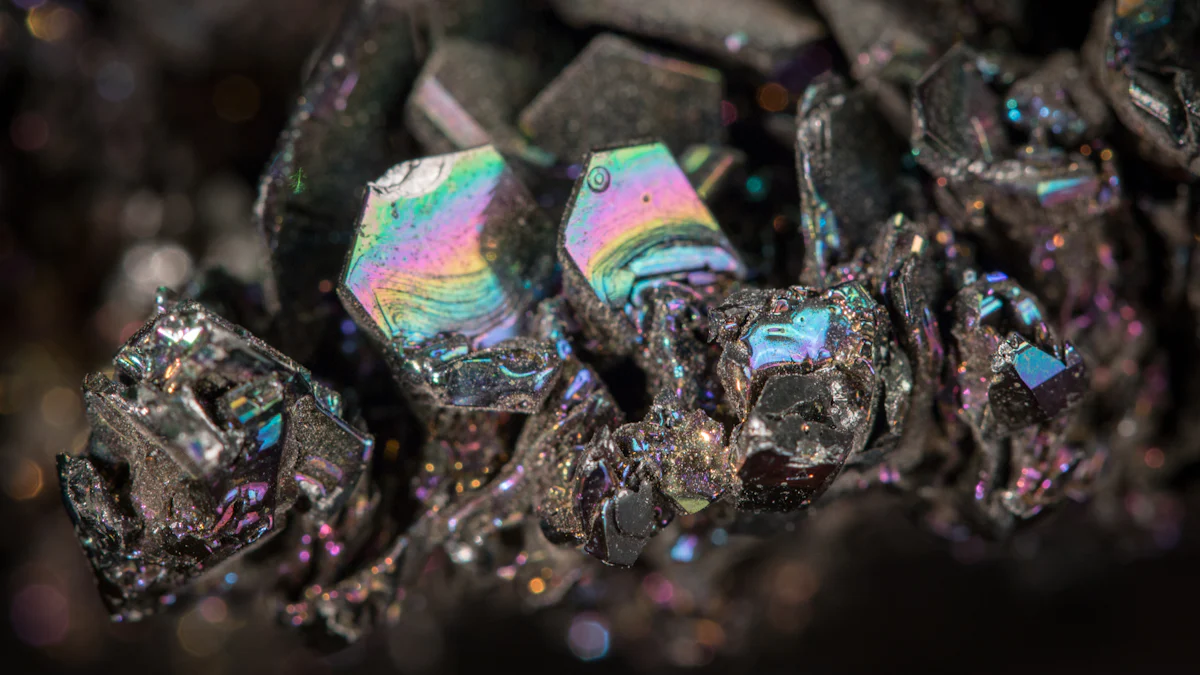

Definition and Significance of Purity Levels

Purity levels in high-purity silicon carbide refer to the percentage of silicon carbide present in the material compared to impurities. These levels are critical in determining the material's suitability for advanced applications. High purity ensures that the material exhibits consistent electrical, thermal, and mechanical properties. Industries such as semiconductors and aerospace rely on precise purity levels to achieve optimal performance. Even minor deviations in purity can lead to defects, reduced efficiency, or compromised durability. Understanding and controlling these levels is essential for maintaining the reliability of high-purity silicon carbide in demanding environments.

Common Impurities in High-Purity Silicon Carbide

Types of Impurities (e.g., metallic, non-metallic)

Impurities in high-purity silicon carbide can be broadly categorized into metallic and non-metallic types. Metallic impurities include elements like iron, aluminum, and titanium, which may enter during production or from raw materials. Non-metallic impurities, such as oxygen, nitrogen, and carbon, often arise from environmental exposure or chemical reactions during processing. Each type of impurity affects the material differently, making their identification and removal a priority.

Effects of Impurities on Material Properties and Applications

Impurities can significantly alter the properties of high-purity silicon carbide. Metallic impurities may increase electrical conductivity, which is undesirable in semiconductor applications. Non-metallic impurities can weaken the material's thermal stability or mechanical strength. These changes can reduce the efficiency of power electronics, compromise the durability of aerospace components, or limit the performance of renewable energy systems. Maintaining low impurity levels ensures the material meets the stringent requirements of high-performance applications.

Importance of Purity in High-Performance Applications

High-purity silicon carbide plays a vital role in industries requiring precision and reliability. In semiconductors, high purity minimizes defects, ensuring consistent performance in power electronics and high-frequency devices. Aerospace applications demand materials that can withstand extreme temperatures and corrosive environments, which is only possible with high-purity silicon carbide. Renewable energy systems, such as inverters and converters, benefit from the material's efficiency and longevity when purity levels are maintained. The importance of purity cannot be overstated in these critical applications.

How Are Purity Levels Measured and Maintained?

Traditional Methods for Measuring Purity

Chemical Analysis Techniques

Chemical analysis techniques play a foundational role in assessing the purity of high-purity silicon carbide. These methods involve breaking down the material to identify and quantify impurities. Wet chemical analysis, for instance, uses reagents to dissolve the sample and detect contaminants through titration or precipitation. Gravimetric analysis measures the mass of impurities after chemical reactions. These techniques provide reliable results but often require significant time and expertise.

Spectroscopic Methods

Spectroscopic methods offer a faster and more precise alternative for measuring purity. Techniques like atomic absorption spectroscopy (AAS) and inductively coupled plasma optical emission spectroscopy (ICP-OES) detect trace elements by analyzing the light emitted or absorbed by atoms. These methods excel at identifying metallic impurities in high-purity silicon carbide. Their high sensitivity makes them indispensable for industries requiring stringent purity standards.

Advanced Techniques for Purity Measurement

Mass Spectrometry

Mass spectrometry has revolutionized impurity detection in high-purity silicon carbide. This technique ionizes the sample and separates ions based on their mass-to-charge ratio. It can detect impurities at parts-per-billion levels, making it ideal for applications demanding extreme precision. Time-of-flight and quadrupole mass spectrometers are commonly used for this purpose.

X-Ray Diffraction (XRD)

X-ray diffraction (XRD) provides a non-destructive method for analyzing the crystalline structure of silicon carbide. By measuring the diffraction patterns of X-rays passing through the material, XRD identifies structural defects and impurities. This technique ensures the material meets the required specifications for high-performance applications.

Ensuring Purity During Production

Raw Material Selection and Processing

Maintaining purity begins with selecting high-quality raw materials. Producers must source silicon and carbon with minimal impurities. Advanced processing techniques, such as chemical vapor deposition (CVD), further enhance purity by controlling the reaction environment. These steps ensure the final product meets the desired purity levels.

Quality Control and Process Optimization

Quality control measures are essential throughout production. Techniques like real-time monitoring and statistical process control (SPC) help identify deviations early. Process optimization, including refining temperature and pressure conditions, minimizes contamination risks. These practices ensure consistent production of high-purity silicon carbide.

Specifications and Standards for High-Purity Silicon Carbide

Industry Standards and Grades

5N and 3N Purity Levels

The purity levels of high-purity silicon carbide are often classified into grades such as 5N and 3N. These grades indicate the material's purity percentage, with 5N representing 99.999% purity and 3N representing 99.9% purity. The 5N grade is typically used in applications requiring exceptional precision, such as semiconductors and aerospace components. The 3N grade, while slightly less pure, remains suitable for many industrial uses where ultra-high purity is not critical. These classifications help manufacturers and end-users select the appropriate material for their specific needs.

Variations Across Applications

Different industries demand varying purity levels based on application requirements. For instance, the semiconductor industry prioritizes 5N purity to minimize defects in electronic devices. In contrast, applications like abrasives or certain mechanical components may tolerate lower purity levels. Understanding these variations ensures that high-purity silicon carbide is utilized effectively, optimizing both performance and cost-efficiency.

Key Specifications for High-Purity Silicon Carbide

Electrical and Thermal Properties

High-purity silicon carbide exhibits excellent electrical and thermal properties. Its high thermal conductivity allows efficient heat dissipation, making it ideal for power electronics. Additionally, its wide bandgap ensures superior electrical performance, even under high temperatures. These properties are critical for industries like renewable energy and electric vehicles, where efficiency and reliability are paramount.

Mechanical Strength and Durability

The material's mechanical strength and durability set it apart from other advanced ceramics. High-purity silicon carbide resists wear, corrosion, and thermal shock, ensuring long-term performance in demanding environments. These characteristics make it a preferred choice for aerospace and defense applications, where components must endure extreme conditions without failure.

Certification and Compliance Requirements

Role of Third-Party Testing

Third-party testing plays a crucial role in verifying the purity and quality of high-purity silicon carbide. Independent laboratories assess the material against industry standards, ensuring it meets the required specifications. This impartial evaluation builds trust between manufacturers and end-users, guaranteeing the material's reliability.

Importance of Meeting Industry Standards

Adhering to industry standards ensures consistency and compatibility across applications. Meeting these standards minimizes the risk of defects and enhances the material's performance. Compliance also facilitates global trade, as many industries require certification before accepting materials for production. Manufacturers must prioritize these standards to remain competitive in the market.

Applications of High-Purity Silicon Carbide and the Role of Purity

Semiconductor Industry

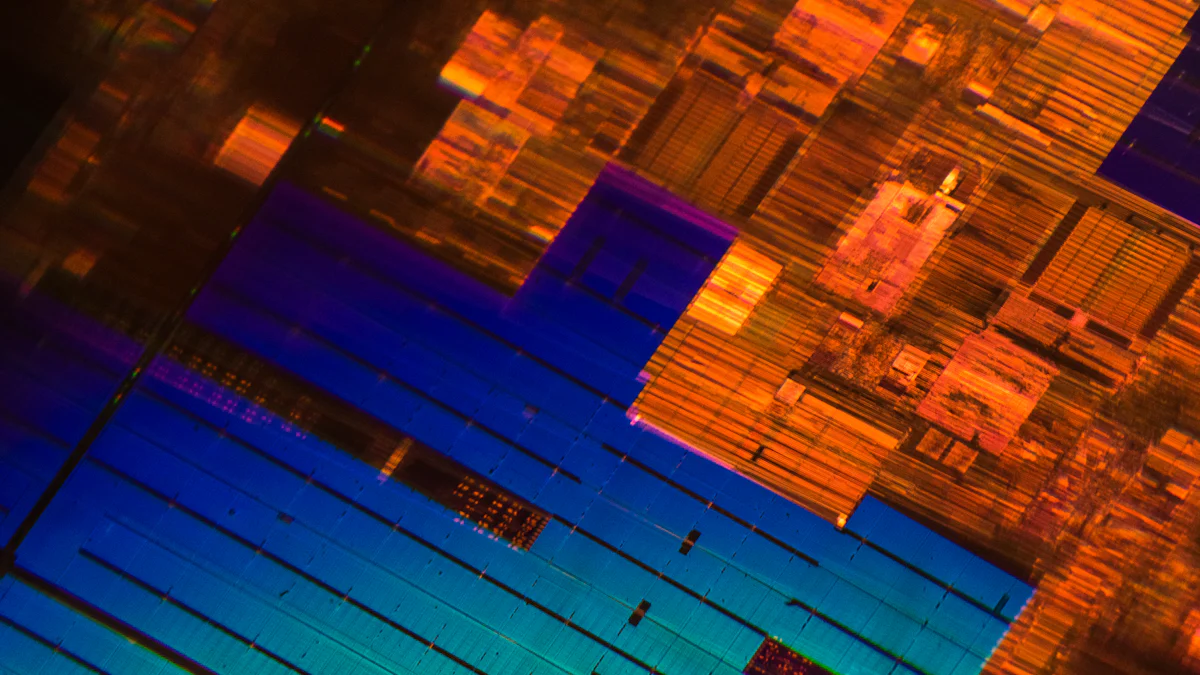

Power Electronics and High-Frequency Devices

High-purity silicon carbide has become indispensable in the semiconductor industry. Its exceptional electrical properties, such as a wide bandgap and high thermal conductivity, make it ideal for power electronics and high-frequency devices. These components, including diodes and transistors, operate under extreme conditions where traditional materials fail. Silicon carbide enables efficient energy conversion, reduced heat generation, and compact device designs. This material supports advancements in technologies like 5G networks and electric power systems, where performance and reliability are critical.

Importance of Purity in Reducing Defects

Purity directly impacts the performance of semiconductor devices. Impurities introduce defects in the crystal structure, leading to electrical inconsistencies and reduced efficiency. High-purity silicon carbide minimizes these defects, ensuring consistent performance and longer device lifespans. Manufacturers prioritize purity to meet the stringent demands of modern electronics, where even minor imperfections can compromise functionality.

Aerospace and Defense

High-Temperature and Corrosion-Resistant Applications

Aerospace and defense industries rely on high-purity silicon carbide for its ability to withstand extreme environments. Its high melting point and resistance to oxidation make it suitable for high-temperature applications, such as turbine components and heat shields. Additionally, its corrosion resistance ensures durability in chemically aggressive environments, such as those encountered in space exploration or military operations.

Enhancing Durability and Performance

The mechanical strength of silicon carbide enhances the durability of aerospace and defense components. Its ability to resist wear and thermal shock ensures reliable performance under stress. High-purity silicon carbide contributes to the development of lightweight, high-strength materials, improving fuel efficiency and operational effectiveness in these industries.

Renewable Energy and Electric Vehicles

Use in Inverters, Converters, and Energy Storage

Renewable energy systems and electric vehicles benefit significantly from high-purity silicon carbide. Inverters and converters, essential for energy management, utilize this material for its superior efficiency and thermal performance. Silicon carbide also plays a role in energy storage systems, where it supports high-capacity and long-lasting battery technologies.

Impact of Purity on Efficiency and Longevity

Purity influences the efficiency and longevity of renewable energy and electric vehicle components. Impurities can lead to energy losses and reduced operational lifespans. High-purity silicon carbide ensures optimal performance, enabling sustainable energy solutions and extending the life of critical systems. Its role in improving energy efficiency aligns with global efforts to reduce carbon emissions and promote clean energy adoption.

Understanding purity levels in high-purity silicon carbide is essential for industries that demand precision and reliability. Purity directly influences the material's electrical, thermal, and mechanical properties, making it a cornerstone of performance in applications like semiconductors, aerospace, and renewable energy. Maintaining these levels requires advanced measurement techniques, adherence to industry standards, and rigorous quality control. By prioritizing purity, manufacturers ensure that high-purity silicon carbide meets the stringent requirements of modern technology, enabling innovation and long-term success.

FAQ

What does "5N" purity mean in high-purity silicon carbide?

"5N" purity signifies 99.999% pure silicon carbide, with only 0.001% impurities. This grade is essential for applications requiring exceptional precision, such as semiconductors and aerospace components. Its high purity ensures consistent performance and reliability in demanding environments.

How are impurities removed during silicon carbide production?

Producers remove impurities by using advanced techniques like chemical vapor deposition (CVD) and high-temperature processing. These methods control the reaction environment, ensuring minimal contamination. Selecting high-quality raw materials further reduces impurity levels during production.

Why is purity critical for semiconductor applications?

Purity minimizes defects in the crystal structure of silicon carbide, ensuring consistent electrical performance. Impurities can disrupt conductivity and thermal stability, leading to inefficiencies. High-purity silicon carbide supports the reliability and longevity of semiconductor devices, especially in power electronics and high-frequency systems.

What industries benefit most from high-purity silicon carbide?

Industries like semiconductors, aerospace, defense, and renewable energy benefit significantly. High-purity silicon carbide enhances performance in power electronics, high-temperature components, and energy storage systems. Its unique properties make it indispensable for cutting-edge technologies.

How can manufacturers ensure consistent purity levels?

Manufacturers ensure consistent purity through rigorous quality control, real-time monitoring, and process optimization. Techniques like spectroscopic analysis and mass spectrometry verify impurity levels. Adhering to industry standards and sourcing high-quality raw materials also play a crucial role in maintaining purity.